Operation – Lincoln Electric IM10092 LN-25 PIPE User Manual

Page 20

WIRE FEED SPEED KNOB

Wire Feed Speed, CV Operation

When Across the Arc models are operated with CV

power sources, the wire feed speed will remain a con-

stant value, independent of arc voltage changes, as

along as the arc voltage does not drop below the val-

ues per the following table.

83% Wire Feed Speed

The 83% wire feed speed reduces the wire feed

speed to 83% of the original set value when activated.

For example, if the original wfs = 200 in/min, the feed-

er will regulate to 0.83 x 200 = 166 in/min.

The 83% trigger requires a gun with a dual procedure

switch.

This feature is often useful when welding pipe, and a

“cooler” procedure is required on the bottom portion.

THERMAL LED, MOTOR

OVERLOAD

The thermal light illuminates when the wire drive

motor draws too much current. If the thermal light illu-

minates, the wire drive will automatically shutdown for

up to 30 seconds to allow the motor to cool. To start

welding again, release the gun trigger, inspect the gun

cable, liner (and conduit). Clean and make repairs as

necessary. Start welding again when the problem has

been safely resolved.

For best results, keep the gun cable and conduit as

straight as possible. Perform regular maintenance

and cleaning on the gun liner, conduit and gun.

Always use quality electrode, such as L-50 or L-56

from Lincoln Electric.

Maximum WFS

280

340

440

520

600

Minimum Arc Volts

15 V

17 V

21 V

24 V

27 V

B-3

OPERATION

B-3

(See Customer Assistance Policy in the front of this

Instruction Manual)

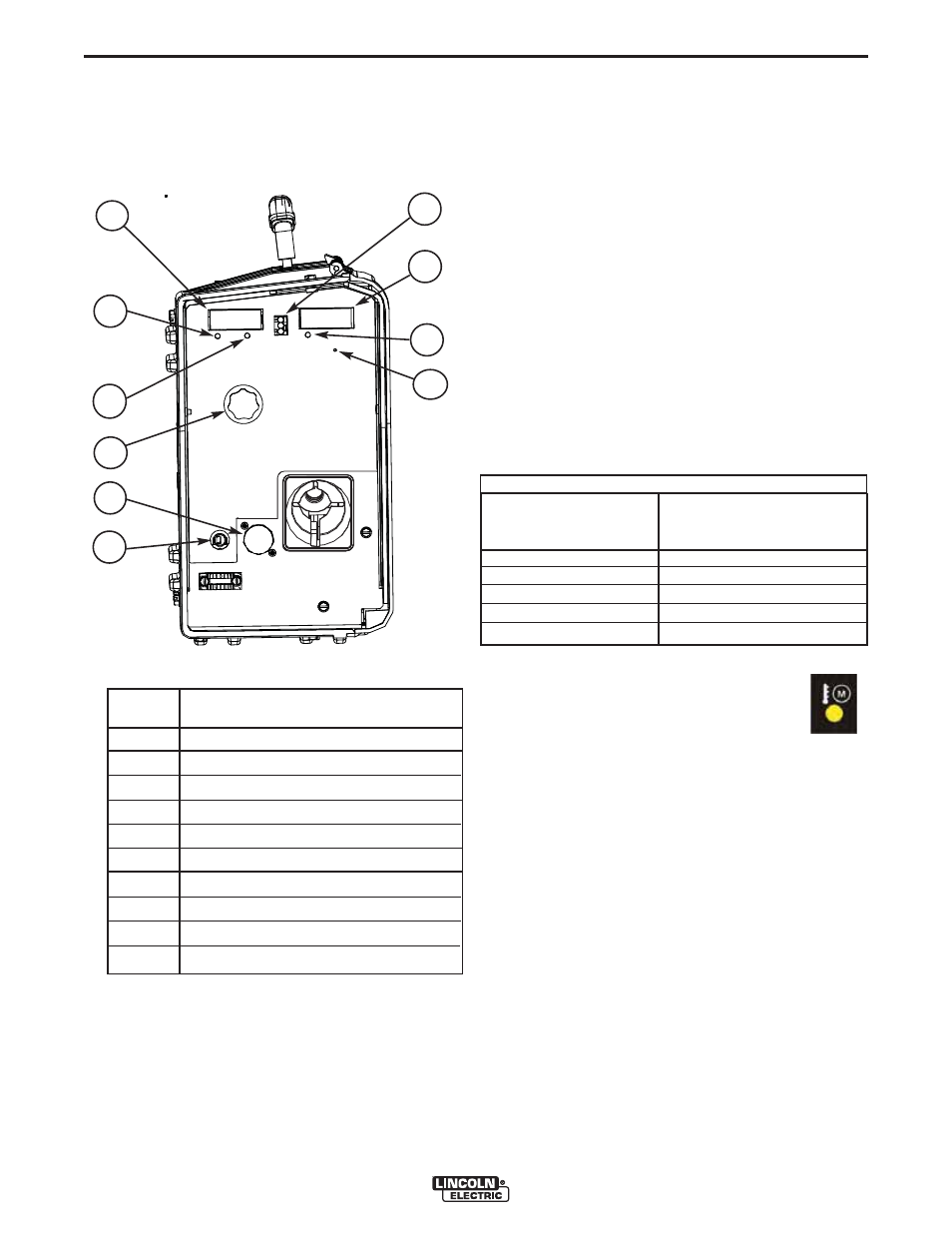

CASE FRONT CONTROLS

(See Figure B.1)

ITEM DESCRIPTION

1

Wire Feed Speed/Amperage Display

2

Wire Feed Speed LED

3

Amperage LED

4

Wire Feed Speed Knob

5

5 pin gun trigger connector

6

Work Clip Connection

7

Thermal LED

8

Voltage Display

9

Voltage LED

10

Set-up Push Button

LN-25™ PIPE

1

5

2

6

7

8

9

10

3

4

FIGURE B.1

CV OPERATION