Warning, Specifications, Helmet information – Lincoln Electric IM10086 SHADE 11 AUTO-DARKENING HELMET User Manual

Page 3: Operating instructions

SPECIFICATIONS

LCD Viewing Area

Cartridge size

UV/IR Protection

Arc Sensors

Light State Shade

Fixed Welding Shade

Power Supply

Power On/Off

Light to Dark Switching Time

TIG Rating

Operating Temperature

Storage Temperature

Total Weight

Compliance

(1)

97 x 35mm (3.82 x 1.83in)

133 x 114mm (5.25 x 4.50in)

Up to Shade DIN 16 at all times

2

DIN 3

DIN 11

Solar cells - Rechargeable Battery

No battery change required

Fully automatic

0.0008 sec (1/1,200 sec)

> 35 amps

23°F ~ 131°F (-5°C ~ 55°C)

-4° ~ 158°F (-20°C ~ 70°C)

493g (17.4 Oz.)

ANSI Z87.1-2003, CSA Z94.3, CE EN379

(1)

Headgear compliance with ANSI Z87.1 is without sweatband installed.

HELMET INFORMATION

This Auto-Darkening Welding Helmet will automatically change from a light state (shade 3) to a

dark state (Shade 11) when arc welding starts.

The filter automatically returns to a light state when the arc stops.

Match your welding application to the shade indicated on the shade chart. (See Page 4)

• Operating temperature: 23°F ~ 131°F (-5°C ~ 55°C).

• Do not use or open the auto-darkening filter if damaged by shock, vibration or pressure.

• Keep the sensors and solar cell clean. Clean the filter cartridge using a soapy water solution

and soft cloth which should be damp but not saturated.

This Auto-Darkening Welding Helmet is designed for use with GMAW, GTAW, MMAW, SMAW,

FCAW welding, or Plasma Arc and air carbon arc cutting.

The cartridge provides protection from harmful UV and IR radiation, in both dark and light states.

The cartridge contains two sensors to detect the light from the welding arc, resulting in the lens

darkening to the welding shade.

• Do not use solvents or abrasive cleaning detergent.

• If cover lens is spattered or covered with dirt, it should be replaced immediately.

• Do not use the helmet without the outside cover lens properly installed.

2

OPERATING INSTRUCTIONS

BEFORE FIRST USE:

The Auto-Darkening welding helmet needs to be charged prior to use and

after extended storage. Face the solar cell on the helmet toward sun light or

light bulb for at least 1 hour before use.

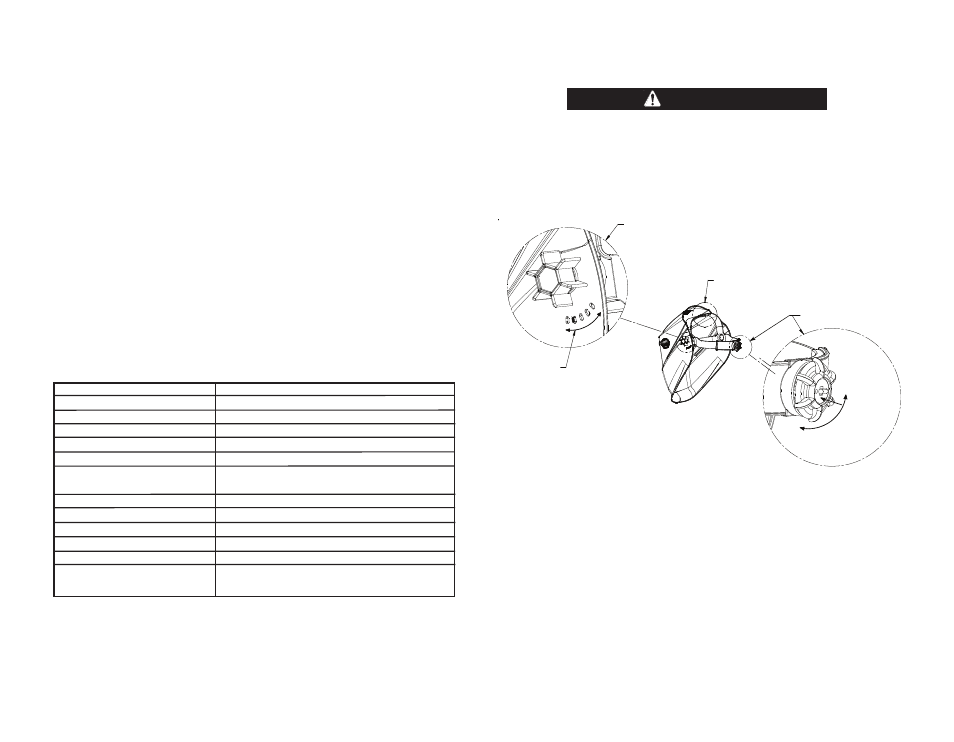

HEADGEAR ADjUSTMENT:

Headband tightness is adjusted by pushing in the ratchet knob and turning to

adjust to desired comfort level. This knob is located at the back of the hel-

met. HEAD GEAR CROWN ADjUSTMENT is made by adjusting crown

strap for vertical placement on the head and snapping the pin into the hole to

lock securely in place.

Tilt: Tilt is adjusted on the left side of the helmet. TILT is adjusted by loos-

ening outside tension knob and releasing the adjustment lever from its cur-

rent location and moving it to another location. Retighten the outside tension

knob when finished.

3

CROWN

ADJUSTMENT

TILT ADJUSTMENT

RATCHET KNOB

PIN HOLES FOR

ADJUSTMENT

CROWN

ADJUSTMENT

TILT ADJUSTMENT

RATCHET KNOB

PIN HOLES FOR

ADJUSTMENT

WARNING