Operation, Warning – Lincoln Electric IM10110 IDEALARC R3R-400 User Manual

Page 10

B-1

OPERATION

B-1

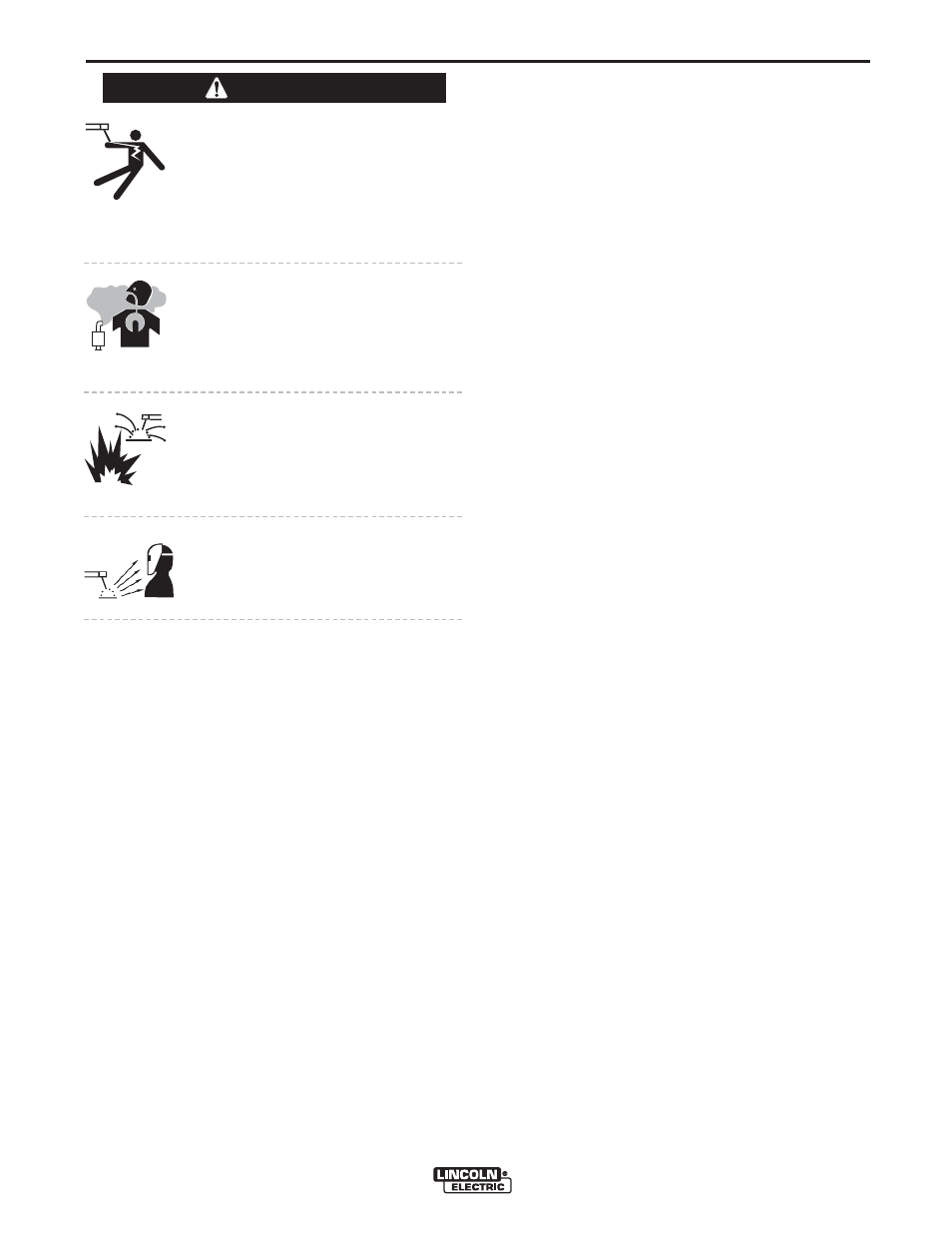

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts

or electrode with skin or wet cloth-

ing.

• Insulate yourself from work and ground.

• Always wear dry insulating gloves.

FUMES AND GASES can be danger-

ous.

• Keep your head out of fumes.

• Use ventilation or exhaust to

•

remove fumes from breathing zone.

WELDING SPARKS can cause fire or

explosion.

• Keep flammable material away.

• Do not weld on containers that

have held combustibles.

ARC RAYS can burn.

• Wear eye, ear and body protection.

NOTE: The P.C. Board is protected by a moisture

resistant coating. When the welder is operated, this

coating will “bake off” of certain power resistors that

normally operate at high temperatures, emitting some

smoke and odor for a short time. These resistors and

the P.C. Board beneath them may become blackened.

This is a normal occurrence and does not damage the

component or affect the machine performance.

1. To Start the Welder, move the “Power” switch to

“On”. This starts the welder and lights the white pilot

light on the machine control panel. This light indi-

cates that the line contactor is energized).

2. Setting Welding Current

a. The “Current Control” dial on the front of the

machine indicates the output current at the

NEMA arc voltage.

On the R3R-400 two dials are used, The “A”

range controls the current over about 1/2 of the

range of the “B” range. A toggle switch on the

control panel allows selection of the desired

range. The output control can be adjusted while

welding.

b. Provisions for remote control are standard on

each power source. A current control switch on

the machine control panel labeled “Current

Control at R3R” or “Current Control Remote” is

provided for selecting the desired mode of oper-

ation, either at the machine or remote, Be certain

the machine remote switch is in the machine

position, unless a remote control is connected,

or the R3R is equipped with optional pocket

amptrol.

c. The “Arc Force Control”, located on the right side

of the front control panel, is calibrated from one

to ten. Lower settings will provide less short cir-

cuit current and a softer arc. A setting that is too

low may cause the electrode to stick in the pud-

dle. Higher settings will provide a higher short

circuit current, a more forceful arc, and possibly

more spatter. For most welding, the dial should

be set at approximately mid range (5

– 6).

Adjustment up or down can then be made

depending on the electrode, procedures, and

operator preference. For most TIG welding appli-

cations adjust this control to minimum for best

operating characteristics.

OPTIONAL EQUIPMENT

1. Remote Current Control – See “Operation”.

2. Amptrol – See “Operation”.

3. Polarity Switch (Factory Installed Only). Permits

changing polarity at the machine output terminals.

(See also “Output Connections”.)

4. Meters – Ammeter and Voltmeter (Factory Installed

Only)

RATINGS

Transformer insulation class 155(F)

IP21 enclosure protection

IDEALARC

®

R3R-400

WARNING