Staub Electronics SM-PROJ-L-WH STRONG - UNIVERSAL PROJECTOR MOUNT FOR PROJECTORS UP TO 50LBS User Manual

Sm-proj-l-blk

SM-PROJ-L-BLK

Strong™ Universal Projector Mount for Projectors up to 50 Lbs. (Black)

For Mounting on a Concrete Ceiling (Fig. 4)

a. Pre-drill four holes into concrete using 3/8” Masonry bit.

Insert Concrete Anchors and tap in with hammer, if necessary.

WARNING: When installing Ceiling Plate on cinder block, first verify there is a minimum of 1-3/8”

of concrete thickness to be used for the Concrete Wall Anchors. Do not drill into mortar joints!

Be sure to mount in a solid part of the block, generally 1”minimum from the side of the block.

Cinder block must meet ASTM C-90 specifications. It is suggested that a standard electric drill on slow

setting is used to drill the hole instead of a hammer drill to avoid breaking out the back of the hole

when entering a void or cavity. Concrete must be 2000 psi density minimum. Lighter density concrete

may not hold concrete anchor.

Make sure that the supporting surface will safely

support the combined load of the equipment and

all attached hardware and components.

b. Insert four Lag Screws into the Concrete Anchors

through the Extended Ceiling Plate.

WARNING: Tighten screws so that the Extended

Ceiling Plate is firmly attached, but do not over-tighten.

Over-tightening can damage the screws, greatly

reducing their holding strength.

c. Insert Extension Pole (UL Listed SM-FIXPOLE series, not

included) into Extended Ceiling Plate. Lock pole in

place with two M5 set screws.

d. On bottom of Extension Pole, thread on Low-Profile

Ceiling Plate, making sure the arrow (on bottom)

faces the screen when installed. Tighten Security Screw

(pre-installed) to lock Low-Profile Ceiling Plate onto Extension

Pole to set in place.

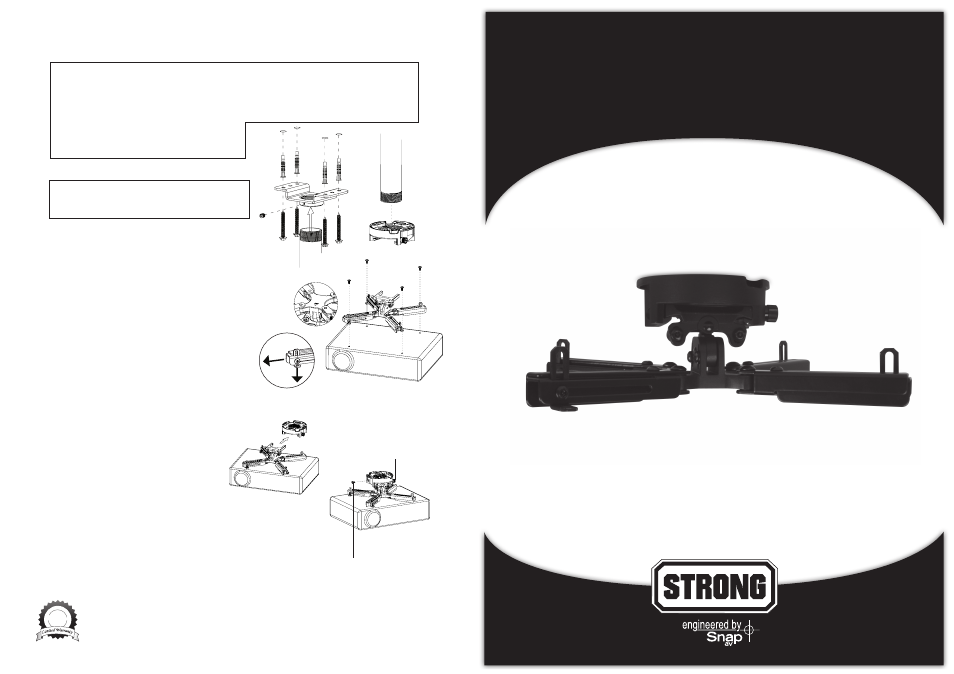

Step 3: Attach the Projector Mount Body

(Fig. 5)

a. Slightly loosen all screws so arms easy rotate and extend to

match the holes on the projector. Making sure the arrow

on bottom points toward the projector lens, attach the

Projector Mount Body onto projector using supplied M3,

M4, M5 or M6 Socket Screws and M2 or M4 Allen Key.

b. Depending on the surface of the projector, lowering

the Angle Brackets on the end of the arms to get a flush

mounting may be necessary (Fig 6).

NOTE: Position center of gravity of projector to the middle

of the mount, if possible.

Step 5: Assemble Projector Mount Body

with Low-Profile Ceiling Plate

a. While holding projector, slide top of Projector

Mount Body into the Low-Profile Ceiling

Plate as indicated (Fig. 7).

b. Using either a Philips Head Screwdriver or

fingers, push in and turn lock screw (attached

to Low-Profile Ceiling Plate) to secure.

c. Using 4mm Allen key, install 10-32 Socket Security

Screw into opposite side as indicated (Fig. 8).

Adjustments

To change the tilt or roll of the mount for centering the picture,

use Allen key and first loosen screws on Projector Mount Body.

Tilt the projector into the desired position and re-tighten the screws.

Lifetime

Fig 4

Fig 5

Fig 6

Fig 7

Fig 8

Lifetime Limited Warranty

All Strong™ products have a Lifetime Limited Warranty. This warranty includes parts and labor repairs on all

components found to be defective in material or workmanship under normal conditions of use. This warranty

shall notapply to products which have been abused, modified or disassembled. Products to be repaired under

this warranty must be returned to SnapAV or a designated service center with prior notification and an

assigned return authorization number (RA).

For Techincal Support : 1.866.838.5052

10-32 Security Screw

Lock Screw