Joyce DSWJ2410 User Manual

Page 4

4

7. When fastening the load to a jack, make sure the jack is in the retracted position. This

positions the load accurately with respect to the jack screw centerline. Never pull the

screw to one side to make connection with your structure. Fully extend the jack to

make sure the load is aligned with the lifting screw.

8. Jacks should be mounted with S.A.E. Grade 8 bolts or equivalent.

9. Torque all mounting bolts in a symmetric pattern to avoid damage to the sleeve.

10. Shaft and coupling guards are the responsibility of the user.

11. Optional limit switches furnished with the jacks are NOT preset and require field

adjustment before use. These limit switches do not have stainless steel housings.

Section II

Maintenance

2-1 Lubrication

1. Jacks are lubricated before leaving the factory.

2. For normal operation, jacks should be greased at least once per month. Under

extended use, grease twice monthly or as conditions dictate. Grease through the

fitting on the jack with hand or power operated equipment. Grease with No. 1

Consistency Grease. Do not allow jacks to operate without lubrication. It is the

responsibility of the user to maintain sufficient lubrication of the jack.

3. The products listed below are recommended by the lubricant manufacturers to meet

the requirements for normal operation. The listing of brand names is solely for the

convenience of users of Joyce equipment and their lubricant suppliers; it does not

constitute any endorsement. Joyce/Dayton assumes no responsibilities for the quality,

performance or availability of any listed products

COMPANY .....................................BRAND NAME

Mobilgrease ..................................XHP 461

Shell Oil Company .......................Retinax HD NLGI 1

Shell Oil Company .......................Albina SLC 460

Mobil Oil.........................................Mobilith SHC PM 460

4. For operation above 250° F or extreme loading, c onsult the Engineering Department of

Joyce/Dayton Corp. ([email protected]).

5. Do not operate jack without lubrication.

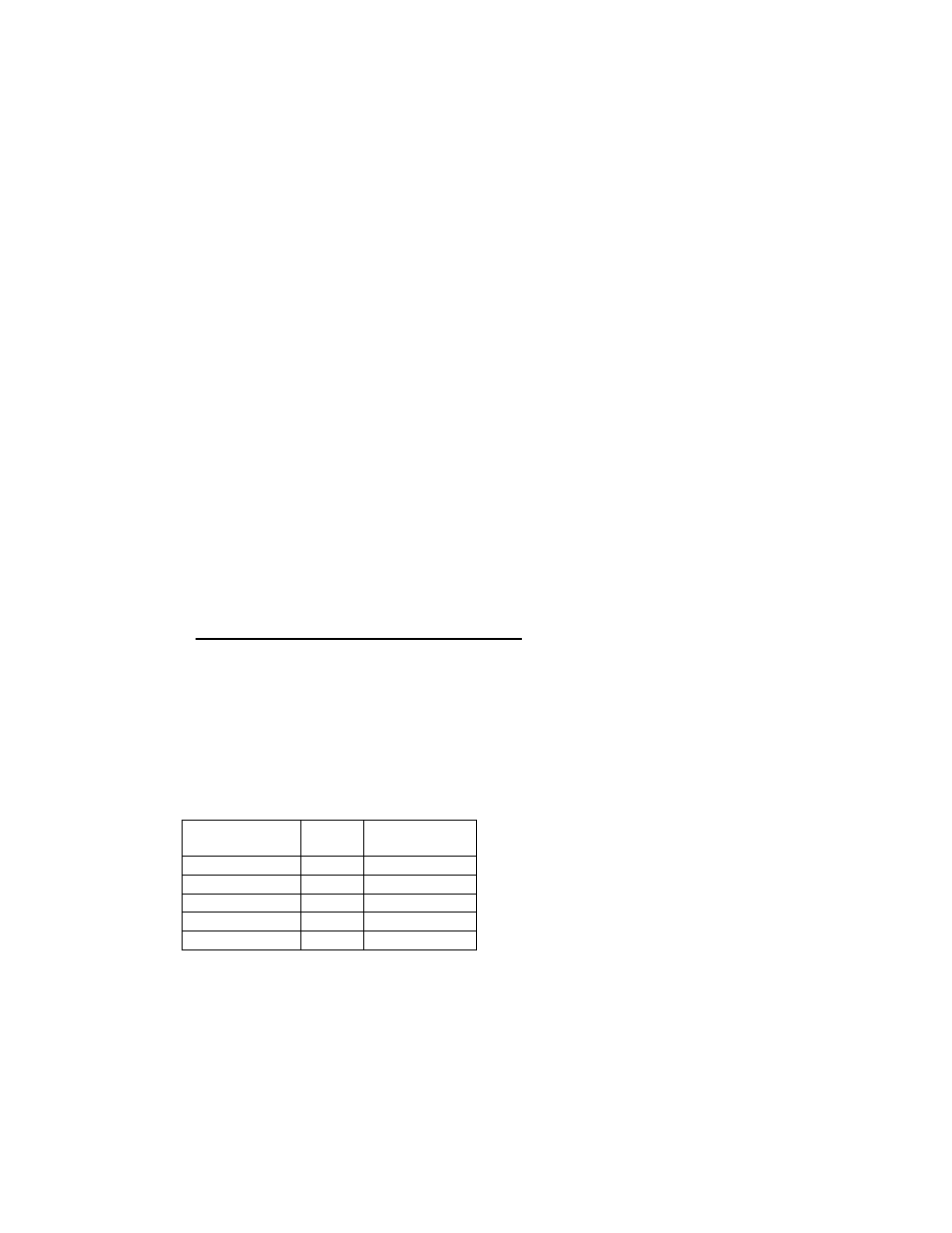

6. Total grease capacity by jack type:

Jack Capacity

Shots

Approximate

Weight

2 ton

13

4.5 oz

5 ton

26

9 oz

10-15 ton

50

17 oz

20 ton

95

33 oz.

25 ton

140

49 oz.

2-2 Repair Parts

Obtain repair parts by contacting Joyce/Dayton Customer Service at (800) 523-5204, (937)

294-6261, (937) 297-7371 (facsimile), [email protected], or call your local sales

representative. When ordering repair parts, please supply the serial number (located on

the jack nameplate).