D. collector angle, plane, and direction, Collector direction, Collector angle (tilt) – HTP SSU-119SE User Manual

Page 10: Collector plane (horizontal or vertical), E. collector piping, F. collector loop pipe insulation

10

LP-199 REV. 4.15.14

D. COLLECTOR ANGLE, PLANE, AND DIRECTION

1. COLLECTOR DIRECTION

The collector should face the equator. In the northern hemisphere, this

is due south, and in the southern hemisphere, due north. Facing the

collector in the correct direction and angle is important to ensure optimal

heat output. A deviation of up to 15

o

from due south is acceptable, and

will have minimal effect on heat output.

2. COLLECTOR ANGLE (TILT)

It is common for collectors to be installed at an angle that corresponds

to the installation latitude. While adhering to this guideline, an angle of

latitude +/- 10

o

is acceptable, and will not greatly reduce solar output.

The solar collector should be installed at an angle of between 20

– 80

o

to ensure optimal operation.

For year-round domestic hot water, the collector should be tilted to an

angle of equal to the latitude of the installation site. Add 15

o

to the

latitude to optimize for winter performance (space heating). Subtract 15

o

from the latitude to optimize for summer performance (pool heating).

Given the formula above, a solar collector installed at 30

o

N latitude should face due south at an angle of 45

o

for wintertime advantage,

and 15

o

for summertime heating.

Preventing Overheating

To reduce summer heat output, angle the collector for optimal winter absorption. This is achieved by installing the collector at an angle

of around 15

o

above the latitude angle (e.g. 45

o

at 30

o

N latitude). This angle corresponds closely to the angle of the sun in the sky

during the winter months, thus maximizing winter output. Conversely, during the summer when the sun is high in the sky, the relative

collector surface area exposed to sunlight is reduced, cutting overall heat production considerably (by about 15%). This option is ideal

for installations where solar thermal is being used for space heating.

3. COLLECTOR PLANE (HORIZONTAL OR VERTICAL)

The collector could be installed vertically, but may be installed at an angle, such as sideways on a pitched roof. In vertical installations,

collectors may be installed level, or with ¼” pitch towards the return port. See more detail in Part 2, Section D, Number 3.

E. COLLECTOR PIPING

Never use dielectric unions or galvanized steel fittings in the collector loop. Doing so will lead to corrosion, property damage, and

possible early water heater failure. Such damage IS NOT covered by warranty. Use only copper and brass fittings.

Collector piping requires the use of copper and brass fittings in the collector loop. To avoid leaks and fluid loss, copper and brass

ground joint unions should be used to join the collectors. Use only lead-free solder. Engelhard Silvabrite 100 or equivalent is the

required soldering material. Use of 50/50 lead solder is expressly prohibited. Use of galvanized steel, CPVC, PVC or any other non-

rated plastic pipe is prohibited.

Penetrations through walls or other surfaces shall not allow intrusion by insects and/or other vermin. Ensure that all structural

penetrations are properly sealed with an elastomer, such as Tremco “POLYroof”.

Piping in new solar installations may have dirt, grease, solder flux, or other impurities that will affect the quality of HTF over time.

Thorough cleaning is required before charging new solar installations with glycol.

Ensure that there are no dips or low points in solar piping that could trap fluid and possibly rupture in freezing conditions. Copper

plumbers tape or tube strap is the required strapping material. The pipe insulation may not be compressed or crimped by the strapping

material.

The installation of all piping may not reduce the performance or rating of structural members or fire rated assemblies and must adhere

to all applicable local codes and ordinances.

F. COLLECTOR LOOP PIPE INSULATION

The collector loop supply and return lines must be well insulated with high quality, flexible, closed cell insulation to minimize heat loss.

Wall thickness of pipe insulation should not be less than ¾". 1" wall thickness is required in all areas prone to annual hard freeze

conditions. When it comes to pipe insulation the rule is simple: thicker is better. The specified insulation material is HT/Armaflex or

equivalent.

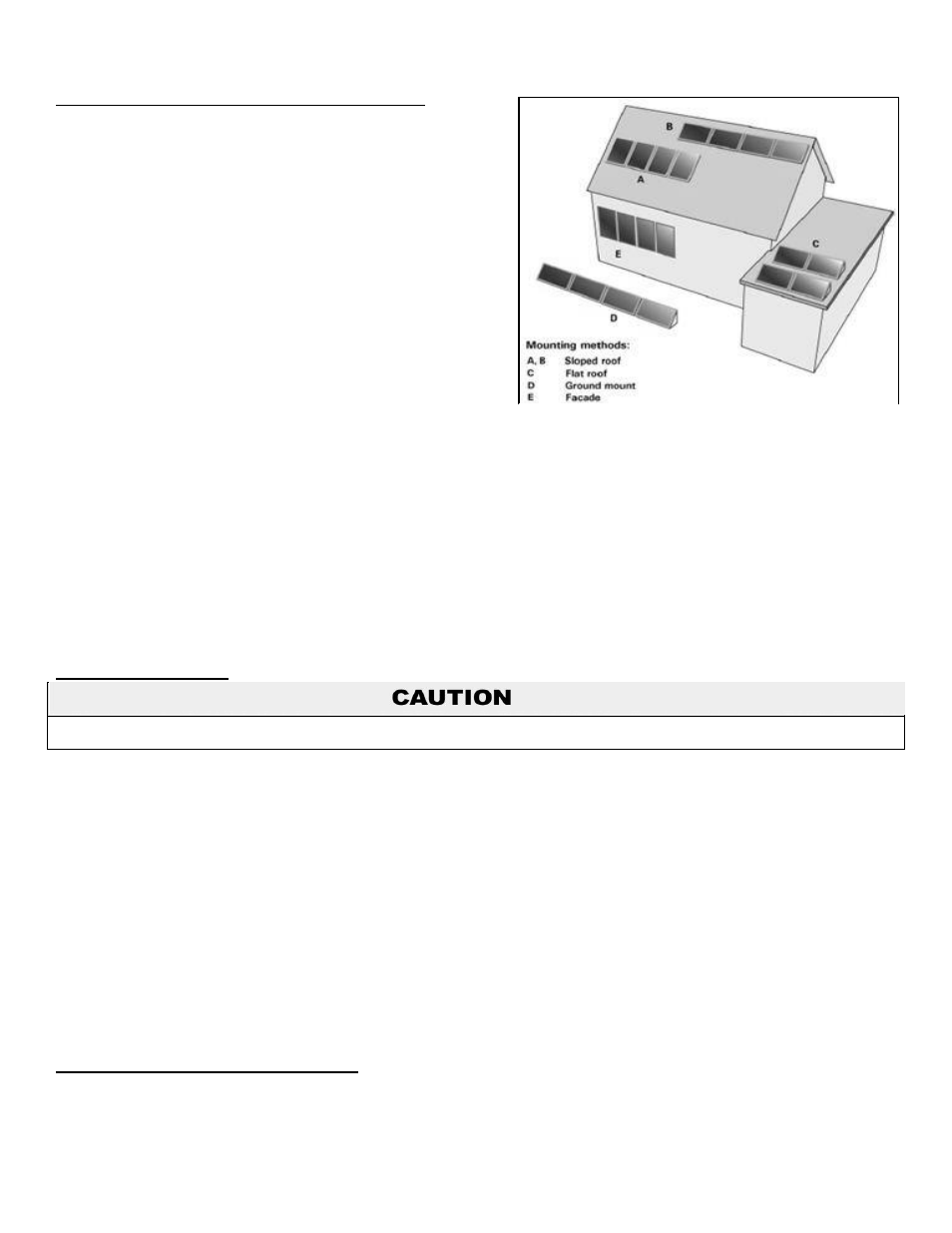

Figure 1 - Suggested placement of solar collectors