Troubleshooting – HTP SSC-119 User Manual

Page 17

17

LP-65 Rev. 3.24.14

RELIEF AND DRAIN VALVE

Relief Valve

Lift and release the relief valve on the water heater. Make

certain that the valve operates properly by allowing several

gallons to flush through the discharge line. Replace if valve is

blocked or does not operate properly.

NOTE: DISCHARGED WATER MAY PRESENT A SCALD

RISK. TAKE CAUTION WHEN OPERATING RELIEF VALVE.

Drain Valve

Open the drain valve and drain a few quarts of water from the

bottom of the tank to flush any hard water deposits. Replace if

valve is blocked or does not operate properly.

NOTE: DRAINED WATER MAY PRESENT A SCALD RISK.

TAKE CAUTION WHEN OPERATING DRAIN VALVE.

FINAL INSPECTION

Check list

Verify that you have completed entire check list. WARNING:

FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY

OR DEATH

Homeowner

Review what you have done with the homeowner.

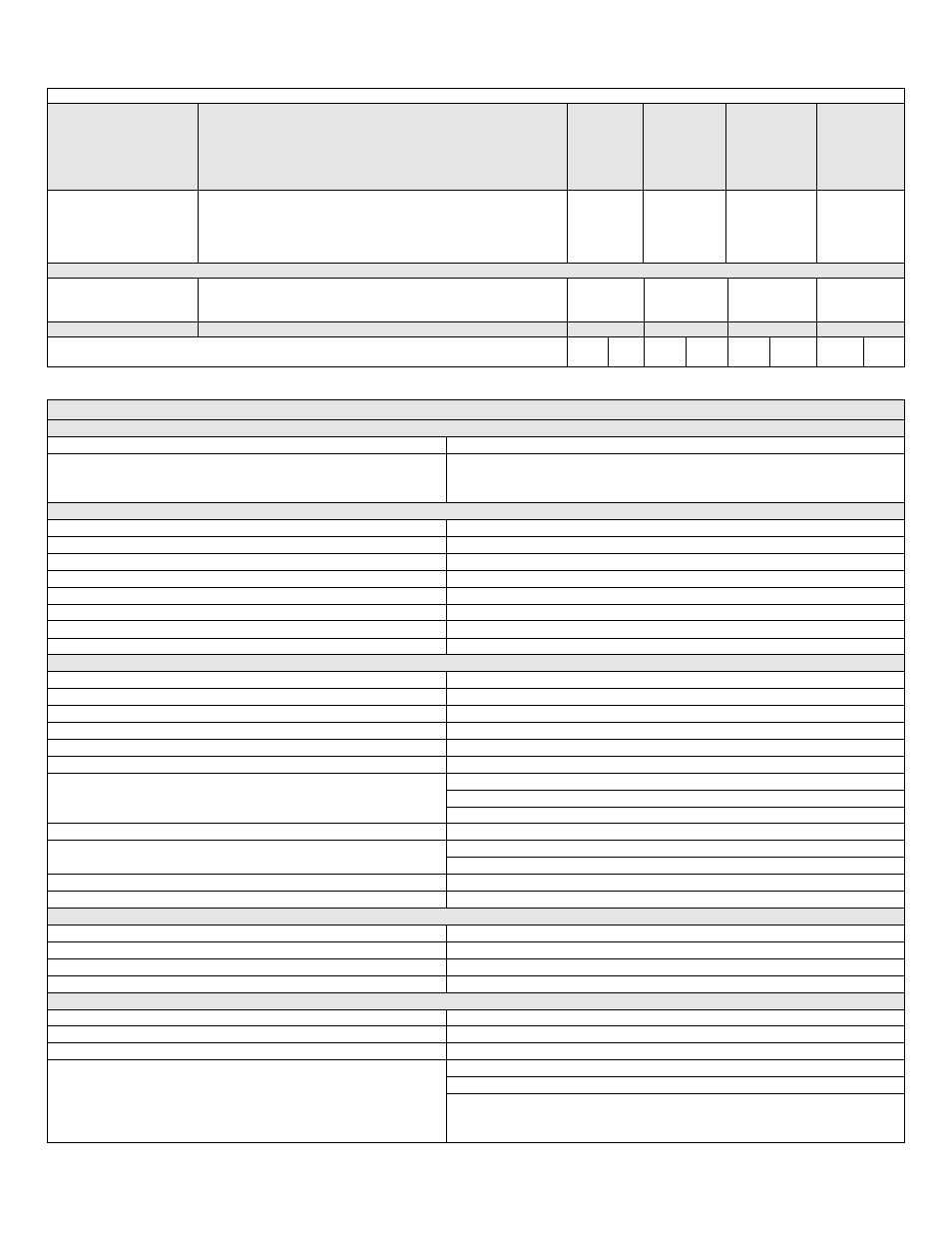

INITIAL AND DATE AFTER INSPECTION/SERVICE. CONTINUE INSPECTIONS

ANNUALLY BEYOND THE FOURTH YEAR.

Table 4 - *If applicable to system.

TROUBLESHOOTING

HOT WATER HAS A ROTTEN EGG ODOR

PROBLEM

POSSIBLE SOLUTION

Supply water has high sulfate or mineral content

Check with water quality specialist in your area. Have water supply

analyzed. Address water quality

issues according to specialist’s

recommendations.

NO HOT WATER

PROBLEM

POSSIBLE SOLUTION

Zone valve not opening

Check or replace.

Circulator not operating

Check or replace

Tank control set too low

Raise tank temperature* (SEE NOTE BELOW)

Boiler control set too low

Raise boiler temperature

Wiring incorrect

Recheck wiring

Tank control failure

Replace control

Air trap in loop

Purge air

NOT ENOUGH HOT WATER

PROBLEM

POSSIBLE SOLUTION

Zone valve restriction

1” full bore replace zone valve

Circulator arrow reversed

Reverse circulator

Boiler temperature too low

Raise boiler temperature

Boiler sized too small

Check sizing chart

Tank sized too small

Check sizing chart

Demand flow rate too high

Check sizing chart

Install mixing valve, raise tank temperature*

Install flow regulator

Air trap in loop

Purge to remove air

Heat and tank come on together

Recheck wiring or coincidence

Draw tank down and lower thermostat. Recheck.

Not enough space heat

Boiler sized too small. Consult chart.

Slow recovery

Circulator head capacity too low

T & P VALVE DISCHARGES

PROBLEM

POSSIBLE SOLUTION

Tank temperature too high

Lower temperature on tank

Water expands when heated

Install expansion tank

Water pressure too high

Install pressure reducing valve

HOT TUBS, SPAS, MULTIPLE SHOWERS, HIGH DEMAND

PROBLEM

POSSIBLE SOLUTION

Pressure too low

Check line pressure for restriction

Recovery of tank slow

Slow startup boiler. See chart.

Not enough hot water

Boiler sized too small. See chart.

Check flow rate and compare to chart

Demand too great. Check flow rates and compare to chart. Install

mixing valve and/or flow restricting valve and raise tank and boiler

temperature*.

Table 5

– See Scald Warning Below