0 inspection – Harrington Hoists and Cranes NER2 Smart Limits Supplement User Manual

Page 8

5.0 Inspection

5.7

Inspection Methods and Criteria

5.7.1

This section covers the inspection of specific items. The list of items in this section is based on

those listed in ANSI/ASME B30.16 for the Frequent and Periodic Inspection. In accordance with

ANSI/ASME B30.16, these inspections are not intended to involve disassembly of the hoist.

Rather, disassembly for further inspection would be required if frequent or periodic inspection

results so indicate. Such disassembly and further inspection should only be performed by a

qualified person trained in the disassembly and re-assembly of the hoist.

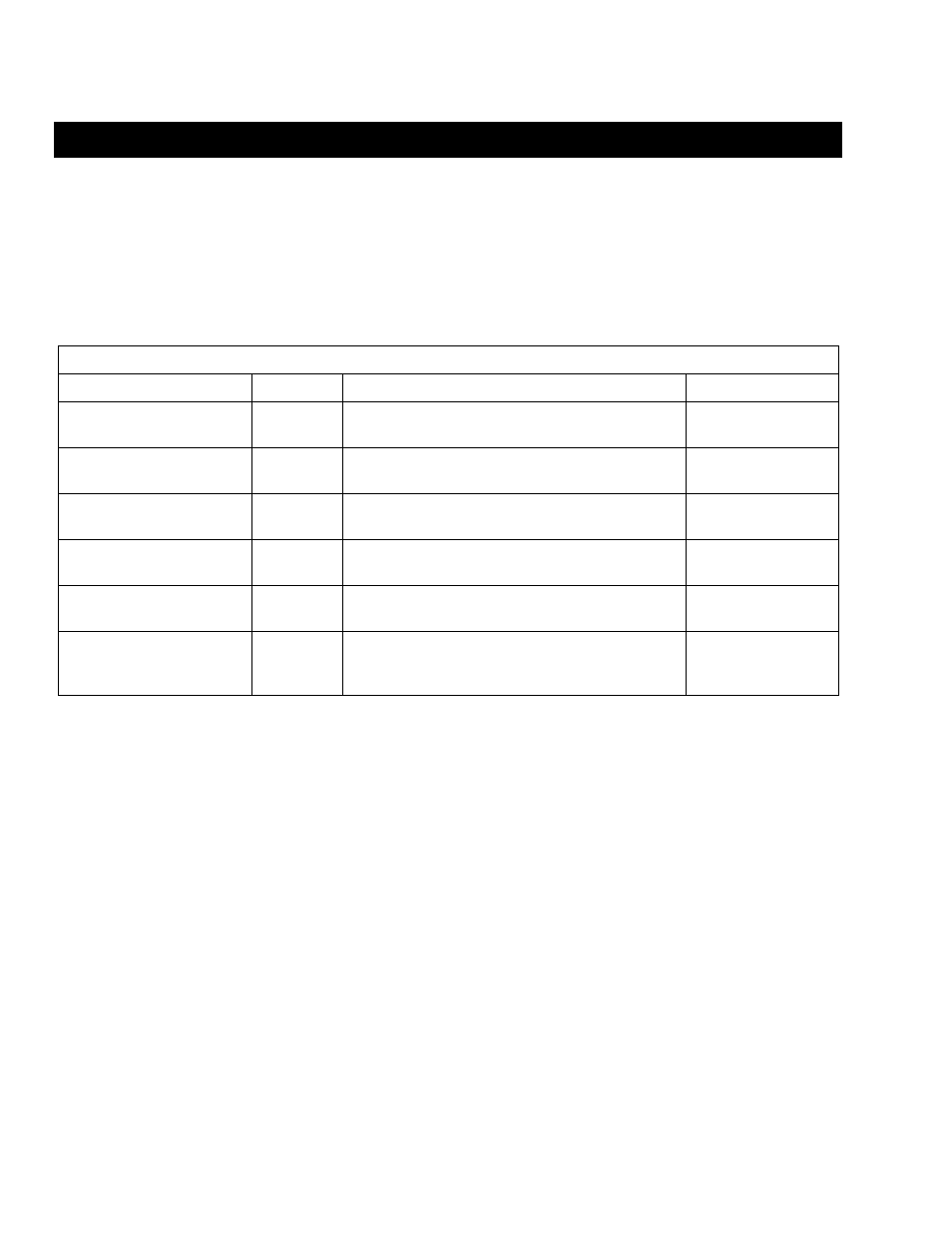

Table 5-10 Smart Limit Components Inspection Methods and Criteria

Item

Method

Criteria

Action

Mounting screws

Visual

Mounting screws should not be loose.

Tighten or replace

as required.

Smart Limit precision

Function

Precision of Smart Limit should not exceed +/-

10mm (0.4in).

Repair or replace

as required.

Photosensor mount

Visual

Photosensor mount should not be loose.

Tighten or replace

as required.

Trigger wheel mount

Visual

Trigger wheel mount should not be loose.

Tighten or replace

as required.

Micro-computer

assembly mount

Visual

Micro-computer assembly should not be loose.

Tighten or replace

as required.

Lead wire guard and lead

wires (for 1/8 ton to 1/2

ton units)

Visual

Lead wires should be located against the lead

wire guard to prevent them from getting

entangled with the trigger wheel.

Move the wires to

proper location.

8