Mounting positions / lubrication – Grove Gear Helical-Worm Cast Iron (S Series) User Manual

Page 5

Phone: (262) 878-1221

Fax: (262) 878-1968

5

Mounting Positions / Lubrication

Motorized Reducers & Gearmotors

The Reducer and Motor are assembled at the factory, and

filled with the proper quantity of lubricant based on your

specified mounting position. Integral Gearmotors are

supplied with 3 phase 230/460v totally enclosed, fan cooled

(TEFC) 1750 rpm general purpose motors. Special integral

gearmotors are available. Consult the factory for details.

Standard Integral Gearmotors and Motorized Reducers are

assembled at the factory with the conduit box and the conduit

opening at the position illustrated in the dimensional section

of the catalog. The user may rotate the body of the motor to

reposition the conduit box (in 90° increments from the

original position). The conduit opening may also be

repositioned at 90° increments from the original position.

Both operations may be performed without disassembling

the drive.

Lubrication

Size 8472 through 8774 Reducers and Gearmotors are filled

with gear lubricant at the factory, to the correct level for the

mounting position specified on the order. This lubricant is

recommended for continuous operation with ambient

temperatures of 40° to 100°F (4° to 38° C) and operating

temperature to 225°F (107° C).

If the mounting position is changed, the oil

quantity must be adjusted to obtain the proper oil level per

the Lubrication Instruction enclosed with each unit. Mounting

position must be one shown on page 4. Consult the factory if

you are not certain of the correct oil level or quantity. Consult

the factory for mounting positions not shown.

For Double and Triple reduction units and the secondary

unit of quad reduction units, use Mobil 600W Cylinder oil,

or equivalent worm gear lubricant (ISO VG 460 AGMA 7

Comp.). For the primary unit of quad reduction units, use

Mobilgear 630 gear lubricant or equivalent (ISO VG 220

AGMA 5 EP).

Consult the factory for recommendations for other ambient

temperatures or intermittent duty.

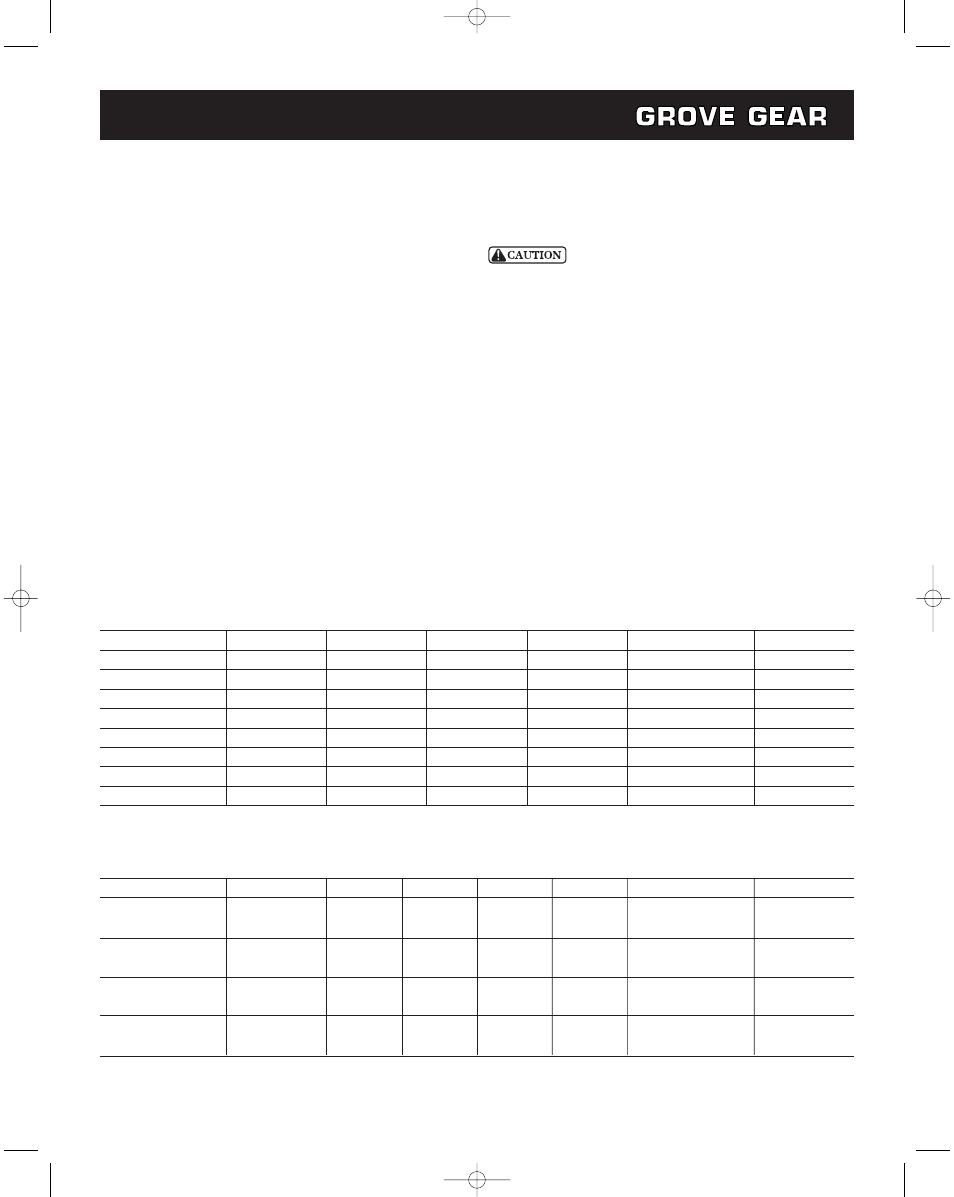

Approximate Oil Capacity (pints) Double and Triple Reduction

Mounting Position

Reducer Size

B3/B6

B8

V5/V5I

V6/V6I

B6/B8I

B3I/B6II

8472

1.7

2.4

1.9

1.9

Contact Factory

2.1

8473

2.1

2.8

2.2

2.2

Contact Factory

2.8

8572

2.0

3.9

3.3

3.3

Contact Factory

3.7

8573

2.8

4.5

3.9

3.9

Contact Factory

4.8

8672

4.3

5.6

5.1

5.3

Contact Factory

6.0

8673

6.3

8.3

7.3

7.3

Contact Factory

8.0

8772

7.7

14.0

11.6

11.6

Contact Factory

12.7

8773

11.2

18.0

15.1

15.1

Contact Factory

16.2

Approximate Oil Capacity (pints) Quadruple Reduction

(1)

Mounting Position

Reducer Size

Unit

B3/B6

B8

V5/V5I

V6/V6I

B6/B8I

B3I/B6II

8674 Primary

1.9

2.2

1.6

1.6

Contact

Factory

2.5

Solid Input Shaft

Secondary

4.3

5.6

5.3

5.3

Contact Factory

6.0

8674

Primary

1.6

3.0

2.3

2.3

Contact Factory

2.3

“C” Face Input

Secondary

3.6

9.0

8.3

8.6

Contact Factory

10.8

8774

Primary

3.0

3.1

2.4

2.4

Contact Factory

3.6

Solid Input Shaft

Secondary

7.7

14.0

11.6

11.6

Contact Factory

12.7

8774

Primary

1.6

3.0

2.3

2.3

Contact Factory

2.3

“C” Face Input

Secondary

7.7

14.0

11.6

11.6

Contact Factory

12.7

(1) Quad reduction units are compound units, the primary and secondary units are filled separately. Refer to the model table above and use the oil

capacities shown.

HelicalWormMan,7-07 8/2/07 11:46 AM Page 5