Maintenance, Installation instructions, Gear reducer drive shaft recommendations – Grove Gear Bravo Aluminum User Manual

Page 5

Maintenance

Your BRAVO

®

reducer has been tested and adjusted at the factory. Dismantling or replacement of components must be done by Factory to maintain

the warranty .

Mounting bolts should be routinely checked to ensure that the unit is firmly anchored for proper operation .

Seals: The BRAVO

®

line of speed reducers utilize premium quality seals which are state-of-the-art in sealing technology . Seals are, however, a wear

item and eventually need to be replaced . Replacement can easily be accomplished by following the procedure below .

1 . Remove the worn seal without damaging the shaft surface or the seal bore. This can be done by drilling a .062” diameter hole in the seal

casing (being careful not to drill into the bearing behind the seal). Screw a #10 sheet metal screw into the hole and pry out the seal.

2 . Clean the seal bore of sealant .

3 . Before installing the new seal, use electrical tape to cover any keyways on the shaft to prevent seal lip damage .

4 . Grease the seal lips with bearing grease and apply a sealant to the seal bore .

5 . Slide the seal onto the shaft being careful not to fold the inner lip over on any shaft steps .

6 . Press the seal into its bore with a sleeve that presses on the seal casing, being careful to keep the seal square in its bore .

If seal leakage has resulted in the loss of a significant amount of lubricant, it may be necessary to add more . Contact Factory for more detail .

Always check for proper oil level after filling. Do not overfill or underfill with oil, or injury to personnel, reducer, or other equipment

may result .

Do not mix different oils in the reducer.

INSTALLATION

INSTRUCTIONS

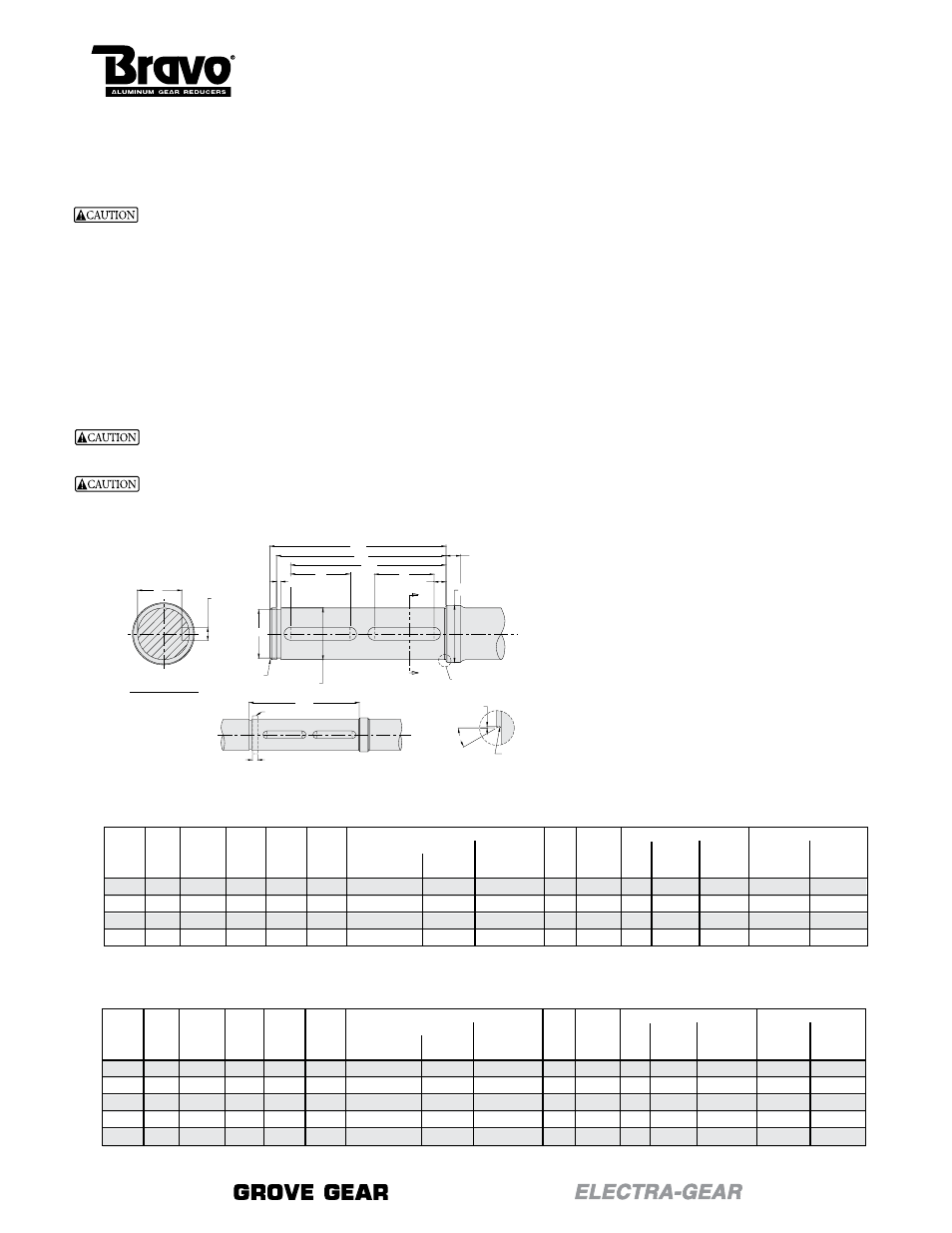

There are several possible methods to retain

a drive shaft into the hollow bore of a gear reducer.

A few common options are listed below:

l

Retain drive shaft with a retaining ring (illustrated above)

l

Retain drive shaft with a locknut

l

Retain drive shaft with a thrust plate and fastener

l

Retain drive shaft with a collar and setscrew

l

Retain drive shaft with a recessed plate and fastener

SPACER

W

BD

DOUBLE ENDED EXTENSION

30° REF

.005/.010

SEE UNDERCUT

DETAIL

UNDERCUT DETAIL

.030R

E

D

C

L

K

J

SECTION: X-X

I

H

G

E

F

A

B

.04x45°

CHAMFER

(2 PLCS - 520, 525 & 534)

DRIvEN SHAFT RECOMMENDATIONS

X

X

Gear Reducer Drive Shaft Recommendations

DRIVEN SHAFT RECOMMENDATIONS l HOLLOW BORE IN INCHES

Dimensions - Inches

* Dimension “W” refers to the width of spacer used.

Retaining Ring

Keyway

Double Extension Details

Series

A

B

C

D

F Groove

Mfg. No.

I

+/- 0.0025

G

J

H +/- 0.0005 E

K

L

BD

W *

+0.005/ - 0.000

+/- 0.002 (Waldes Truarc)

+/- 0.0025 +/- 0.001

+/ 0.0025 +/- 0.001

518 2.80 2.6445 0.43

N/A

0.18

0.086

0.703

5160-75 0.88 0.749 1.15 0.6365 0.1875

3.0755 0.430

520 3.50 3.2725 0.30

3.00 0.23

0.086

0.937

5160-98 1.12 0.999 1.15 0.8565 0.250

3.5735 0.300

525 5.00 4.8225 0.13

4.25 0.22

0.103

1.058

5160-112 1.25 1.124 1.53 0.9785 0.250

4.9535 0.130

534 5.65 5.4315 0.53

5.00 0.28

0.120

1.405

5160-150 1.75 1.499 1.65 1.2815 0.375

5.9625 0.530

DRIVEN SHAFT RECOMMENDATIONS l HOLLOW BORE IN MILLIMETERS

Dimensions - MM

* Dimension “W” refers to the width of spacer used.

Retaining Ring

Keyway

Double Extension Details

Series

A

B

C

D

F Groove

Mfg. No.

I

+/- 0.064

G

J

H

- 0.005/

E

K

L

BD

W *

+0.12/ - 0.00

+/- 0.05

(Waldes Truarc)

-0.020

+/- 0.05 + 0.015/-0.000 +/ 0.064 +/- 0.02

512 60.5 56.223

10

N/A

5

1.1

13

5100-55 19.1

14

20.2 10.8

5

66.383 10.16

518 71.1 67.170

11

N/A

5

1.4

16

5160-66 22.4

18

30.2 14.5

6

78.118 10.92

520 88.9 83.120

8

76.2

5

2.3

23.5

5160-98 28.4

25

30.2 21.0

8

90.767 7.62

525 127.0 122.492

3

108.0

8

2.6

26

5160-106 31.8

28

40.2 24.0

8

125.819 3.30

534 143.5 137.960 14

127.0

9

2.6

32.8

5160-137 44.5

35

50.2 30.0

10

151.448 13.46

www.grovegear.com