Selection information, Safety alert, Class of service – Grove Gear Cast Iron – Narrow (NH Series) User Manual

Page 6: Parts list, Hollow shaft models h, hm, hmq

www.grovegear.com

Selection Information

Read ALL instructions prior to operating reducer. Injury to personnel or reducer failure may be caused

by improper installation, maintenance or operation.

Written authorization from GROVE GEAR / ELECTRA-GEAR is required to operate or use reducers in

man lift or people moving devices.

Check to make certain application does not exceed the allowable load capacities published in the

current catalog.

Buyer shall be solely responsible for determining the adequacy of the product for any and all uses to

which Buyer shall apply the product. The application by Buyer shall not be subject to any implied

warranty of fitness for a particular purpose.

Safety Alert

• Forsafety,BuyerorUsershouldprovideprotectiveguardsoverallshaft

extensionsandanymovingapparatusmountedthereon.TheUserisresponsible

for checking all applicable safety codes in his area and providing suitable guards.

Failuretodosomayresultinbodilyinjuryand/ordamagetoequipment.

• Hotoilandreducerscancausesevereburns.Useextremecarewhenremoving

lubrication plugs and vents.

• Makecertainthatthepowersupplyisdisconnectedbeforeattemptingtoservice

or remove any components. Lock out the power supply and tag it to prevent

unexpected application of power.

• Reducersarenottobeconsideredfailsafeorself-lockingdevices.Ifthese

features are required, a properly sized, independent holding device should be

utilized. Reducers should not be used as a brake.

• Anybrakesthatareusedinconjunctionwithareducermustbesizedorpositioned

in such a way so as to not subject the reducer to loads beyond the catalog rating.

• Liftingsupportsincludingeyeboltsaretobeusedforverticallyliftingthegearbox

only, with no other associated attachments or motors.

• UseofanoilwithanEPadditiveonunitswithbackstopsmaypreventproper

operation of the backstop. Injury to personnel, damage to the reducer or other

equipment may result.

• Overhungloadssubjectshaftbearingsandshaftstostresswhichmaycause

premature bearing failure and/or shaft breakage from bending fatigue, if not

sized properly.

WARNING

Worm Gear Reducers

Installation, Lubrication

and Maintenance Instructions

www.grovegear.com

Page 6

Class of Service

Load conditions must be within cataloged ratings published in the current Grove Gear / Electra-Gear

Catalog (available upon request).

PublishedratingsassumelubricationwithISO460viscositygradepolyglycol(PAG)oil.ContactFactory

for ratings when an alternate lubricant is used.

Warranty From Grove Gear / Electra-Gear-See8050catalogforwarrantytermsandconditions.

www.grovegear.com

Page 7

PARTS LIST

BASIC SINGLE REDUCTION UNIT

(B-STYLE)

ITEM # DESCRIPTION

1

HOUSING

2

PIPEPLUG

3

VENTPLUG

4

SPLASHGUARD

5

INPUTCAP

6

O-RING

7

HEXHEADCAPSCREW

8

INPUTOILSEAL

9

INPUTBEARING(cupandconefor

842andlargerunits)

10

INPUTBEARING(cupandconefor

842andlargerunits)

*11

RETAININGSCREW

12

INPUTWORMSHAFT

13

OUTPUTCOVER-OPEN

14

OUTPUTCOVER-CLOSED

15

O-RING

16

OUTPUTCOVERSHIM(asrequired)

17

OUTPUTOILSEAL

18

OUTPUTBEARING(18A.CONE,

18B.CUP)

19

HEXHEADCAPSCREW

♣ 20

OUTPUTSHAFT-SINGLE

♣ 21

OUTPUTSHAFT-DOUBLE

22

GEARSPACER

23

GEARKEY(onlyusedonsize826

and larger units)

♣ 24

OUTPUTGEAR

*25

INPUTCOVER

26

KEY-OUTPUTEXTENSION

27

KEY-INPUTEXTENSION

28

NAMEPLATE

VERTICAL SHAFT REQUIRED PARTS

(supplied only when mounting

position involves a vertical shaft)

*129

OUTPUTCOVER-CLOSED

*130

OUTPUTCOVER-OPEN

*131

OUTPUTBEARINGGREASE

RETAINER

132

GREASEFITTING

133

SEALEDBALLBEARING

(onlyusedonsize818thru826

units)

♦134

INPUTCOVER

♦136

INPUTBEARINGGREASERETAIN-

ER

*ONLYUSEDONSIZE842ANDLARGER

UNITS

♦ONLYUSEDONSIZE830ANDLARGER

UNITS

♣SUPPLIEDONLYASOUTPUTASSEMBLY

ON813THROUGH824UNITS

Complete information is available online at www.grovegear.com

Continued on next page

MODEL B813-8100

(Basic Unit Components)

SINGLE REDUCTION

7

5

6

11

10

12

27

136

28

4

2

2

26

26

23

21

26

23

22

3

17

13

130

132

132

131

18A

18B

16

15

14

129

19

24

20

22

18A

18B

1

2

17

133

6

25

134

132

8

7

Page 8

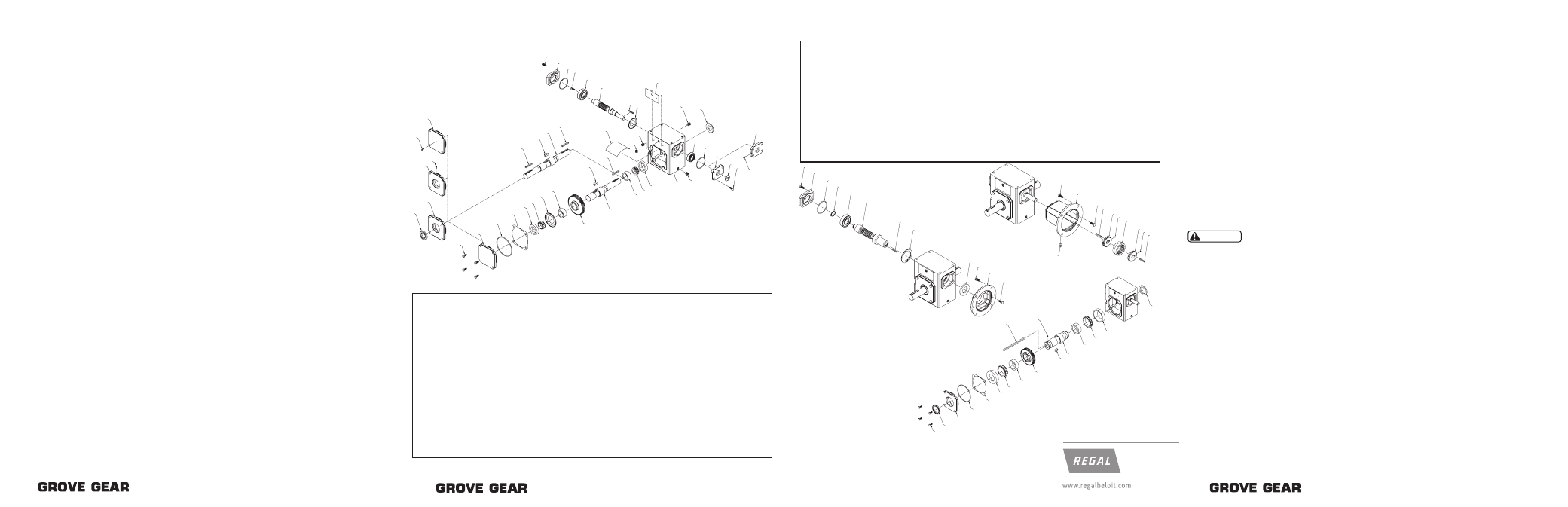

HOLLOW SHAFT MODELS

H, HM, HMQ

(Refer to Single Reduction

Basic Unit Components)

PARTS LIST (cont’d)

MODEL BM813-8100

(Refer to Single Reduction

Basic Unit Components)

MODEL BMQ813-8100

(Refer to Single Reduction Basic Unit

Components)

QUILL MOTOR FLANGE UNIT

(BMQ-STYLE)

40

QUILLMOTORFLANGE

41

INPUTOILSEAL

42

HEXHEADCAPSCREW(flangeto

housing)

43

RETAININGRING-SHAFT

*44

RETAININGRING-HOUSING

45

QUILLINPUTSHAFT

46

KEY-INPUT

47

HEXHEADCAPSCREW(motorto

flange)

HOLLOW OUTPUT SHAFT UNIT

(H-STYLE)

51

OUTPUTCOVER

52

OUTPUTOILSEAL

53

OUTPUTBEARING(53A.CONE,

53B.CUP)

54

GEARSPACER

♣ 55

OUTPUTSHAFT

56

SETSCREW

57

GEARKEY(onlyusedonsize826

and larger units)

♣ 58

OUTPUTGEAR

59

OUTPUTKEY

LONG MOTOR FLANGE AND

COUPLING KIT (BM-STYLE)

110

“C”FACEMOTORFLANGE

111

HEXHEADCAPSCREW

(flange to housing)

112

COUPLINGKEY-REDUCERSHAFT

113

SETSCREW-REDUCERSHAFT

114

COUPLINGGEAR-

REDUCERSHAFT

115

COUPLINGSLEEVE

116

SETSCREW-MOTORSHAFT

117

COUPLINGGEAR-MOTORSHAFT

118

COUPLINGKEY-MOTORSHAFT

119

HEXHEADCAPSCREW

(motor to flange)

120

PLASTICPLUG

ForthefullWormGear

Reducer Installation,

Lubrication and

Maintenanceinstructions,

visit: www.grovegear.com

119

110

111

112

114

113

115

117

116

118

120

7

5

6

43

5

10

45

46

44

41

47

40

42

19

52

51

15

16

53B

53A

54

58

59

56

57

55

54

53A

53B

52

A Regal Brand

Grove Gear

Union Grove, Wisconsin 53182

PH: 262-878-1221

FAX: 262-878-1968

© 2013 Regal-Beloit Corporation

Rev2, 01-13 7471G/01-13/BH/PDF ONLY