Grove Gear Cast Iron – Narrow (NH Series) User Manual

Page 5

www.grovegear.com

Page 2

• Testrununittoverifyoperation.Iftheunittestedisaprototype,thatunitmustbe

of current production.

• If the speed reducer cannot be located in a clear and dry area with access to

adequate cooling air supply, then precautions must be taken to avoid the ingestion

of contaminants such as water and the reduction in cooling ability due to exterior

contaminants.

• Mounting bolts should be routinely checked to ensure that the unit is firmly

anchored for proper operation.

Important Information

In the event of the resale of any of the goods, in whatever form, Resellers/Buyers will include the following

language in a conspicuous place and in a conspicuous manner in a written agreement covering such sale:

The manufacturer makes no warranties or representations, express or implied, by

operation of law or otherwise, as to the merchantability or fitness for a particular

purpose of the goods sold hereunder. Buyer acknowledges that it alone has deter-

mined that the goods purchased hereunder will suitably meet the requirements of

their intended use. In no event will the manufacturer be liable for consequential,

incidental or other damages. Even if the repair or replacement remedy shall be

deemed to have failed of its essential purpose under Section 2-719 of the Uniform

Commercial Code, the manufacturer shall have no liability to Buyer for consequential

damages.

Resellers/Buyers agree to also include this entire document including the warnings above in a con-

spicuous place and in a conspicuous manner in writing to instruct users on the safe usage of the product.

This instructions manual should be read together with all other printed information such as catalogs, supplied by

Grove Gear / Electra-Gear.

General Operation

1. Run the motor which drives the reducer and check the direction of reducer output rotation. Consult

motor nameplate for instructions to reverse the direction of rotation.

2. Attaching the load: On direct coupled installations, check shaft and coupling alignment between

speed reducer and loading mechanism. On chain/sprocket and belt/pulley installation, locate the

sprocket or pulley as close to the oil seal as possible to minimize overhung load. Check to verify that

the overhung load does not exceed specifications published in the catalog.

3. Highmomentumloads:Ifcoastingtoastopisundesirable,abrakingmechanismshouldbeprovided

to the speed reducer output shaft or the driven mechanism.

The system of connected rotating parts must be free from critical speed,

torsional or other type vibration, no matter how induced. The responsibility

for this system analysis lies with the purchaser of the speed reducer.

CAUTION

CAUTION

www.grovegear.com

Page 3

Installation

1. Mounttheunittoarigidflatsurfaceusinggrade5orhigherfasteners.Themountingfastenersshould

bethelargeststandardsizethatwillfitinthebasemountinghole.Shimasrequiredunderflangeor

base feet which do not lie flat against the mounting surface.

2. For shipment, pipe plugs are installed in the unit and a vent plug is packed separately.

After mounting the unit in position, remove the appropriate pipe plug and install the vent

plug in the location shown on page 5. On double reduction units both the primary and the

secondary must be vented. Failure to vent the unit can cause premature seal wear or

loss of seal and oil. These conditions are not covered by warranty. Check for correct oil

level. Contact the Factory for level and vent recommendations on non-standard mounting

positions.

3. Connect motor to speed reducer.

Depending upon gear geometry and operating conditions worm gear reducers may or may not back-

drive. Use of a brake or external holding device is required if any evidence of backdriving is not desired.

Specialconsiderationshouldbegiventohighinertia loads connected to the output shaft. Consult the

factory for further details.

DONOTCHANGEMOUNTINGPOSITIONSWITHOUTCONTACTINGFACTORY.

Altering the mounting position may require special lubrication provisions which

must be factory installed.

Do not operate the reducer without making sure it contains the correct amount

ofoil.Donotoverfillorunderfillwithoil,orinjurytopersonnel,reducerorother

equipment may result.

A unit cannot be used as an integral part of a machine superstructure which would

impose additional loads on the unit other than those imposed by the torque

being transmitted either through a shaft-mounted arrangement, and any shaft

mounted power transmitting device.

(e.g., sprockets, pulleys, couplings)

For safe operation and to maintain the unit warranty, when changing a factory

installed fastener for any reason, it becomes the responsibility of the person

making the change to properly account for fastener grade, thread engagement, load,

tightening torque and the means of torque retention.

Lubrication - Standard and

WASHGUARD

®

/ Platinum Units

AllstandardreducersorderedfromFactoryarefilledwithMobilGlygoyle460polyglycol(PAG) lubricant

orequivalentsuitableforcontinuousoptionwithina-10°Fto120°Fambienttemperaturerange.Double

andtriplereductionunitshaveseparateoilsumpsandmustbefilled/checkedindependently.Priorto

startup,verifythattheoilisatthelevelshownonpage6.Lubricanttypeisstampedonallnameplates.

WARNING

CAUTION

CAUTION

CAUTION

www.grovegear.com

Page 4

Change Intervals: Standardcompoundedlubricants(non-synthetic)shouldbechangedeverysixmonths

or2500operatinghours,whichevercomesfirst.Factoryinstalledsyntheticlubricantsshouldbechanged

only when performing maintenance that requires gearbox disassembly.

Oil should be changed more often if reducer is used in a severe environment (i.e. dusty,

humid).

In the Food and Drug Industry (including animal food), consult the lubrication

supplierforrecommendationoflubricantswhichareacceptabletotheFoodandDrug

Administration and/or other authoritative bodies having jurisdiction. Factory supplied

PAGoilisacceptableforincidentalfoodcontact(NSFH1)foruseinandaroundfood

processing areas.

Do not mix different oils in the reducer. Grove Gear / Electra-Gear reducers are

shipped standard with PAG lubricant – this lubricant is not compatible with conventional

mineralorPAOsyntheticoils.

Special Lubrication Requirements - Size 818 and Larger

UnitsshippedfromFactoryareassembledtoproperlylubricateallinternalcomponentsbasedonaspe-

cificassumedmountingorientation.Ifasize818orlargerunitwillbemountedinanorientationdifferent

fromitsoriginalintension,asshowninproductcatalog,orrunwithsustainedinputspeedslessthan1200

RPM,itshouldbespecifiedwiththeorder.Theunitcanthenbemodifiedtoassureproperlubrication.

Theprecision-madegearsandbearingsinGroveGear/Electra-GearSpeedReducersrequirehigh-grade

lubricants of the proper viscosity to maintain trouble-free performance. All standard reducers ordered

fromthefactoryarefilledwithISOviscositygrade460polyglycol(PAG) lubricant. If oil needs to be

added or changed, ONLY compatible polyglycol lubricants should be used. Contact the factory for

more information.

Oil Capacities (ounces) - Standard Units

Always check for proper oil level after filling. Capacities vary somewhat with model and

mountingposition.Oilshouldrisetobottomedgeoflevelhole.Donotoverfill.

CAUTION

CAUTION

CAUTION

Mounting

UNIT SIZE

Position

813 815 818 821 824 826 830 832 842 852 860 870*

880* 8100*

WormOver

4 12 12 20 24 40 56 72 112 188 312 560

768

1152

WormUnder

8 16 20 28 40 60 84 108 152 304 328 524

820

1280

VerticalOutput

4 16 16 28 32 48 68 88 128 248 320 332

460

640

VerticalInput

4 16 16 24 32 48 72 92 128 248 325 584

800

1200

ExtendedBearing

N/AN/AN/A N/AN/A N/AN/A 8 12 17 27

640

1008

1632

Worm Over

onSecondary

N/AN/AN/A N/AN/A N/AN/A 192 308 320 485 805

114

1716

UnitofDouble

Reduction

StainlessSteel+

WASHGUARD

®

-All

6 14 18 26 32 50 78 98 N/A N/A N/A N/A

N/A

N/A

MountingPositions

CAUTION

www.grovegear.com

Page 5

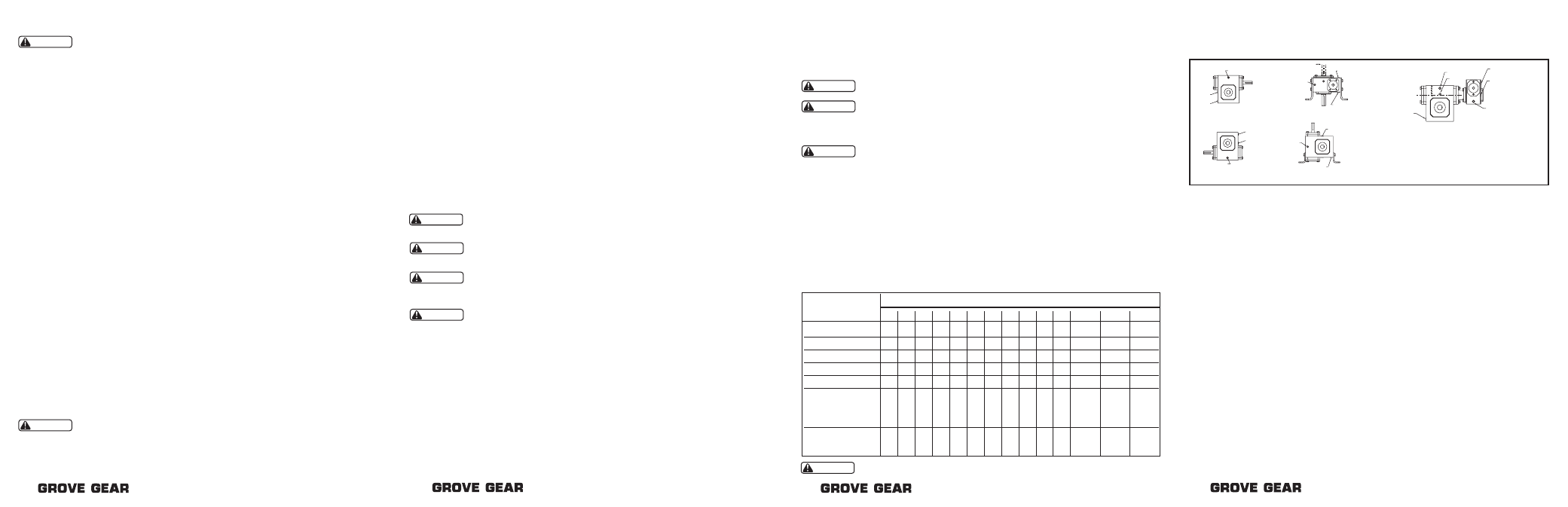

Standard Gear Reducer Mounting Positions

& Vent Plug, Level and Drain Locations s

LEVEL

DRAIN

VENT

DRAIN

LEVEL

VENT

LEVEL*

VENT

DRAIN

LEVEL

DRAIN

VENT

DRAIN

LEVEL

VENT

DRAIN

LEVEL

VENT

Worm Over

Worm Under

Vertical Input

Vertical Output

Double Reduction Worm-Worm

* Size 842 - 860 (far side plug).

Note: High oil level applies to all size 842 & larger

secondary & tertiary units regardless of primary

unit type.

(All primary units have

their own oil level.)

Maintenance - Standard Units

Your Grove Gear / Electra-Gear reducer has been tested and adjusted at Factory. Dismantling or

replacement of components must be done by Grove Gear / Electra-Gear to maintain the warranty.

1.

Frequentlychecktheoillevelofthereducer.Ifoillevelislow,(refertoreducerventandlevel

position chart) add proper lubrication through the filler plug until it comes out the oil level plug.

2.

Inspect vent plug often to insure it is clean and operating.

3.

Alwayscheckforproperoillevelafterfilling.Donotoverfillorunderfillwithoil,orinjuryto

personnel, reducer, or other equipment may result.

4.

Donotmixdifferentoilsinthereducer.

Seals: The Grove Gear / Electra-Gear line of speed reducers utilizes premium quality seals which are the

state-of-the-artinsealingtechnology.Sealsare,however,awearitemandeventuallyneedtobereplaced.

Replacement can be easily accomplished by following the steps below:

1.

Remove the worn seal without damaging the shaft surface or the seal bore. This can be done by

drillinga.062diameterholeinthesealcasing(beingcarefulnottodrillintothebearingbehind

theseal).Installa#10sheetmetalscrewintotheholeandpryouttheseal.

2.

Clean the seal bore of sealant.

3.

Before installing the new seal, use electrical tape to cover any keyways on the shaft to prevent

seal lip damage.

4.

Greasetheseallipswithbearinggreaseandapplyasealanttothesealbore.

5.

Slidethesealintotheshaftbeingcarefulnottofoldtheinnerlipoveronanyshaftsteps.

6.

Pressthesealintoitsborewithasleevethatpressesonthesealcasing,beingcarefultokeep

the seal square in its bore.

s

DoesnotapplytoStainlessSteel,WASHGUARD

®

or units with Enviroseal option.