Grant Part #4198 - Standard Installation Kit User Manual

Grant Water equipment

1.

Point wheels straight ahead and disconnect battery or pull

horn fuse before starting removal of the old wheel so horn

won’t short out and blow during installation.

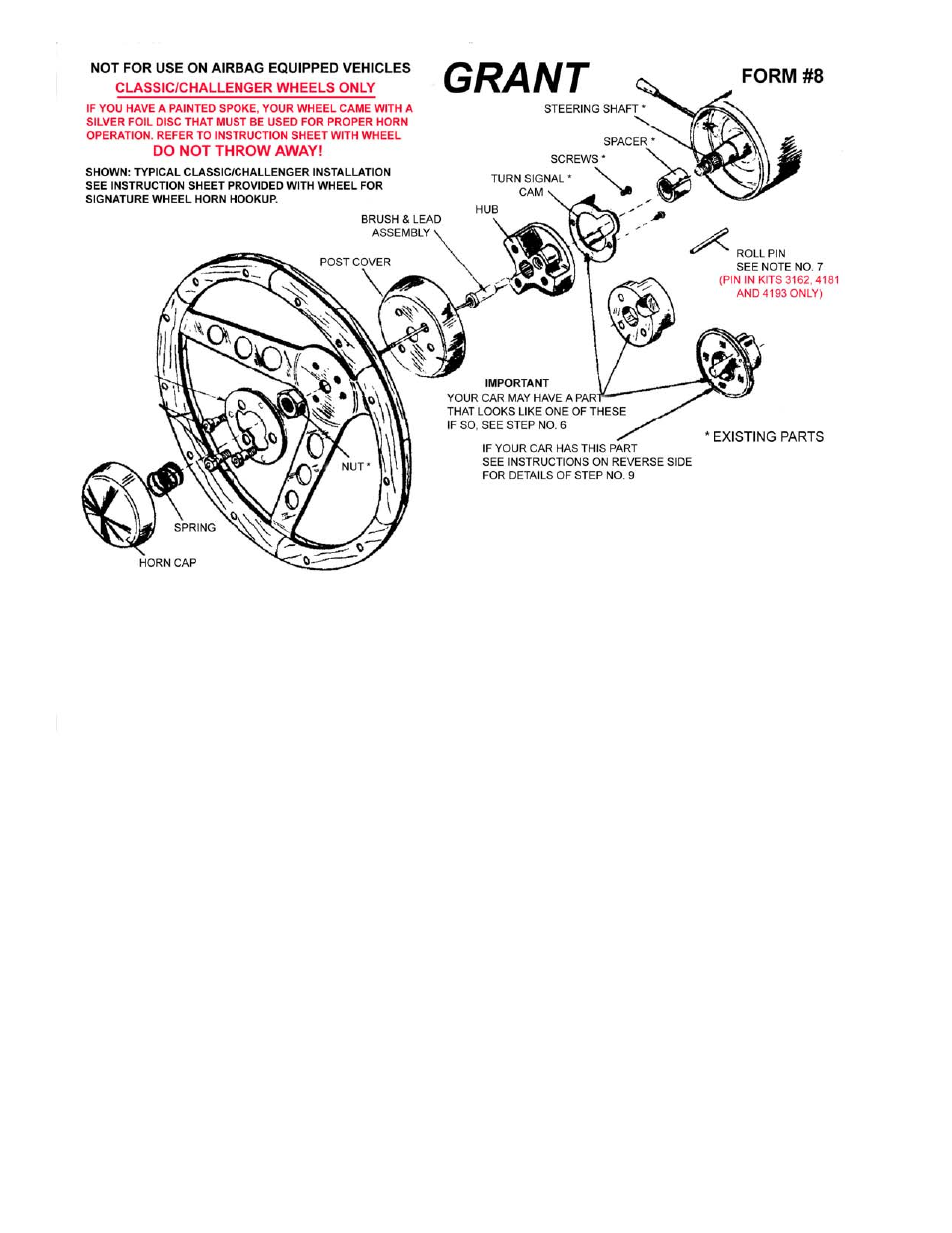

2.

Remove horn mechanism. This is normally done by one

or more of the following steps:

a) Press down on horn cap or ring and turn.

b) Remove emblem cap from its snapped-in condition by

grasping it and pulling toward you, or pry loose.

c) Horn Ring and emblem may be secured by screws

which are concealed in rear side of wheel spokes.

If one of the above operations has not removed all of the

horn parts, it will have exposed the remaining screws to

permit easy removal of the balance of such parts.

3.

Remove nut which holds wheel to shaft.

4. Mark shaft as to which is the top of the wheel.

5. With conventional puller (or GRANT puller 5891), use the

two tapped holes which you will find in the hub of old

wheel to pull off the steering shaft.

If a puller is not available, you may improvise an efficient

one to do the job. By drilling two holes of the proper size in

a short steel bar and using two screws of the proper

length you can tighten them and pull the old wheel very

easily.

6. If there is a turn signal cancellation device, such as

illustrated in diagram, attached to the back of your old

steering wheel, remove this part and reinstall it in the

same

position on the back side of custom hub.

7. If your old steering wheel has a pin inserted in the back

side, note its location. You will find a roll pin furnished in

your kit. Insert this pin in the back side of custom hub

using pin location of old wheel as a guide.

BEFORE PROCEEDING FURTHER

READ GENERAL NOTES AT BOTTOM

8. Position custom hub on splined shaft, observing that “top”

is located in accordance with the mark which you made in

Step No. 4.

9.

Insert brush assembly in recessed hole in hub.

10. Position post cover and wheel on hub using the three

shoulder bolts provided, but do not tighten at this time.

11. Check to see if wheel is in the proper position and, if

correct, install the wheel retainer nut and tighten.

12. Remove shoulder bolts and reinstall same through

retainer contactor ring so that the

fiber side is toward

you.

Tighten shoulder bolts, connect wire lead to retainer.

13. Position spring on nut (you may find tape a help). Place

horn cap in position by aligning dimples in cap with reliefs

in fiber material and push until dimples pass the fiber.

Turn cap left or right until tight (1/4”-1/2”).

14. Reconnect battery or replace horn fuse and enjoy

your

new

wheel.

GENERAL NOTES

a) It is generally wise to apply grease to the horn contact

surface on which the brush assembly rides. This will

reduce wear on the parts and does not interfere with the

electrical

circuit.

b) When tightening the three shoulder bolts, please keep in

mind that excessive torque will result in damage to the

hub. The wheel retainer nut, if properly tightened, will

firmly hold hub/wheel assembly to steering shaft.

TORQUE REQUIREMENTS

SHOULDER BOLTS 10-12 FT/LBS

STEERING SHAFT NUT 25-30 FT/LBS

On the Web: www.grantproducts.com

Rev. 4/09 by J.F. 97508-00-01

- Part #4193 - Standard Installation Kit Part #4187 - Standard Installation Kit Part #4181 - Standard Installation Kit Part #4161 - Standard Installation Kit Part #4160 - Standard Installation Kit Part #4159 - Standard Installation Kit Part #4158 - Standard Installation Kit Part #3163 - Standard Installation Kit Part #3162 - Standard Installation Kit