Maintenance, Checking for leaks – SKC 222-Series Low Flow Pump User Manual

Page 8

6

Maintenance

Checking for Leaks

To function properly and provide correct pumping volume, the diaphragm

must be free from leaks and close positively. Remove cover plate and check the

following:

Intake Valves

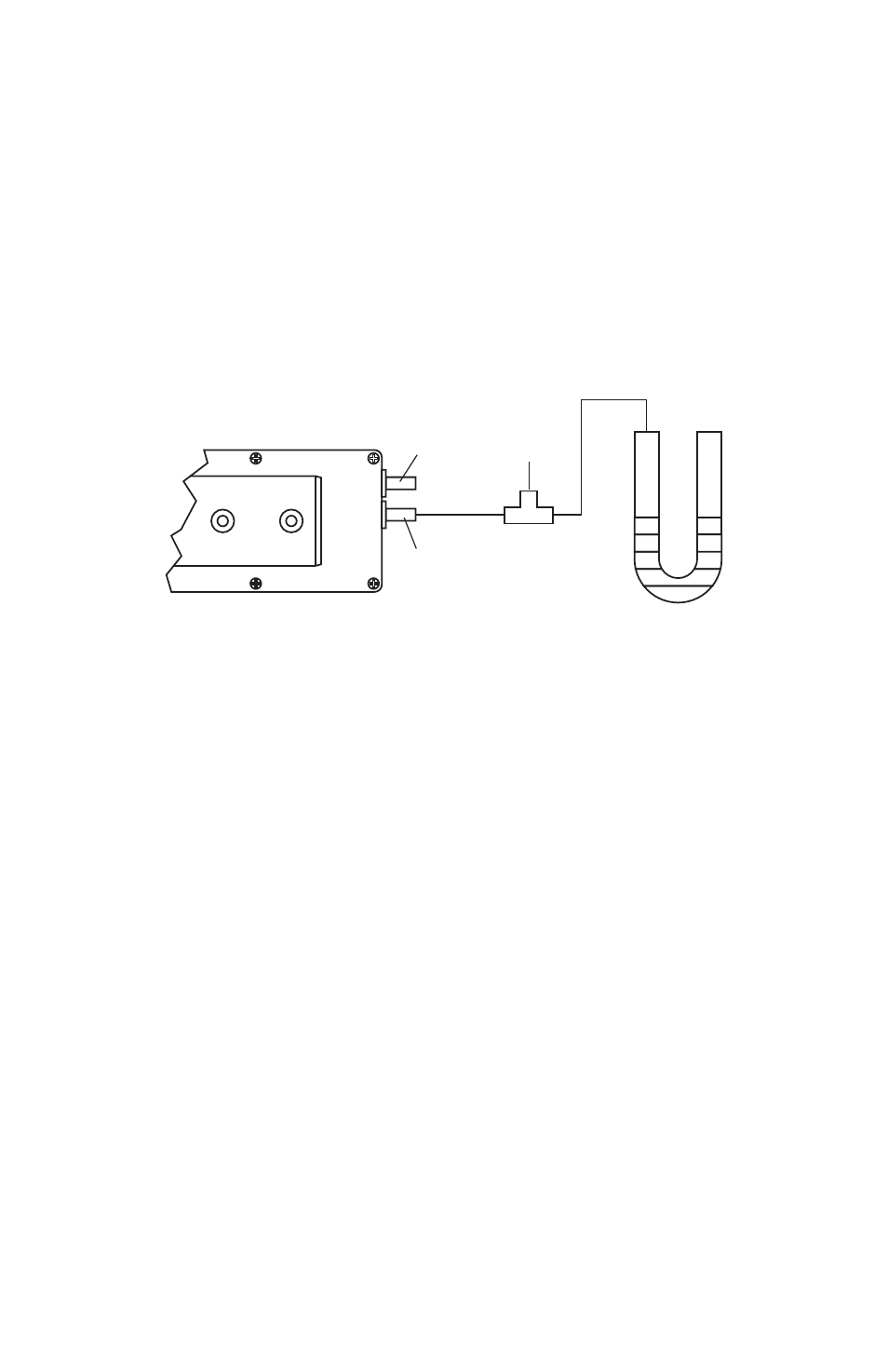

1. To check the intake valves for leaks, connect a water manometer and a tee

connection to the pump inlet as shown in Figure 1 below.

2. On the open end of the tee, draw vacuum by mouth until 4 to 5 inches of

water vacuum register on the manometer.

3. Seal off the open end of the tee and watch the manometer. The water level

should drop less than one-half inch in ten seconds.

Diaphragm and Valve System Integrity

1. With the water manometer and tee connected to the inlet (see Figure 1 above),

seal off the outlet of the pump and introduce positive pressure through the

open end of the tee until 4 to 5 inches of water register on the manometer.

2. While maintaining the pressure, seal off the open end of the tee and watch

the manometer. The water level should drop less than one-half inch in ten

seconds.

Exhaust Valve Seating

1. Disconnect the tee and water manometer from the pump inlet and connect

them to the outlet of the pump.

2. Introduce positive pressure through the open end of the tee until 4 to 5 inches

of water register on the manometer.

3. While holding this pressure, seal off the open end of the tee. Watch the

manometer. The water level should drop less than one-half inch in ten

seconds.

Back of Pump

Inlet

Water manometer

Outlet

(exhaust)

Open end

of tee

Figure 1.