Reversomatic 4000 250ES2 User Manual

Page 3

790 Rowntree Dairy Road, Woodbridge ON, Canada L4L 5V3

Tel: 905-851-6701 Fax: 905-851-8376 [email protected]

w w w . r e v e r s o m a t i c . c o m

.. 3 ..

HOOD INSTALLATION (BE SURE POWER SUPPLY IS OFF BEFORE STARTING INSTALLATION)

1. Attach the damper (optional) section as shown on the previous page to the hood, align with ductwork in cabinet or wall.

2. Guide the electrical cable into the knockout opening and hang the hood on screws previously installed. Tighten screws

securely (see Fig. 2)

3. When installing duct work make sure that damper

normally closes and opens freely, when blower is ON.

4. Run proper wiring to the hood location i.e. 120V / 60Hz AC Power source, with ground.

5. Connect the power supply to the hood leads, White to White, Black to Red and the ground wire to the green grounding

screw. Wiring must confirm to local and national electrical codes and must be done by a qualified person. (See Fig.3)

CLEANING INSTRUCTIONS

(DISCONNECT THE HOOD FROM POWER SUPPLY BEFORE CLEANING OR SERVICING)

1. Clean your range hood with a mild detergent or mild soap, NEVER USE HARSH ALKALIS OR ABRASIVES.

2. Completely dry the range hood with soft dry cloth before restoring power. NEVER IMMERSE ELECTRICAL PARTS IN

WATER.

3. Aluminum mesh grease filter may be washed using mild soap or detergent. However, heavy grease buildup may require

replacement with a new REVERSOMATIC grease filter.

(optional)

2. We recommend that after installation the bottom of the hood should be no less than 20” and no more than 30” above the

stove’s heating elements or burners.

3. Holding the hood in place, mark location of mounting screws in narrow end of keyhole slot in each corner of the hood.

4. Start the 4 mounting screws included with hood, but let them project so later the hood may be hung on them using the

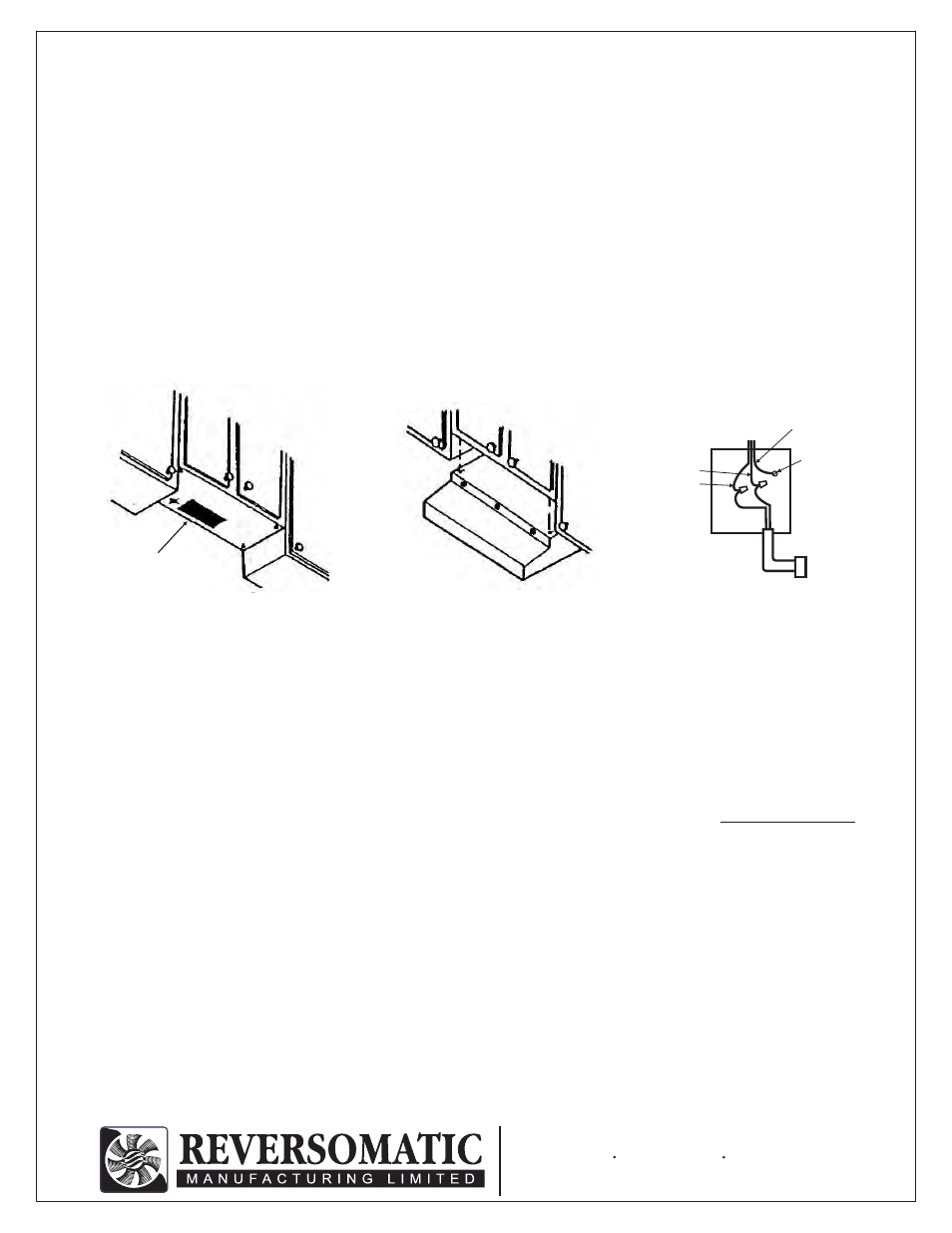

keyhole mounting holes. (See Fig.1)

5. Mark the bottom of the cabinet if the top electrical knockout on the hood will be used or the wall if using rear electrical

knockout. Refer to the dimensions in the drawing for proper hole location. (Remove the appropriate electrical knockout

from the hood by using a screwdriver)

6. Using a 1 1/4” drill bit, drill the opening for the electrical connection (see Fig.1). If drilling in the wall, extra care should be

taken so existing electrical cables are not cut, creating a hazard.

7. Making the cabinet or wall for the duct opening selected following the dimensions in the drawing.

8. Using a saber saw or keyhole saw, cut the duct opening. If cutting in the wall, extra precaution should be taken so

existing electrical cables are not cut, creating a hazard.

Fig. 1

Preparation for

top outlet

Fig. 2

Fig. 3

FROM

HOOD

GREEN

GROUND

SCREW

GROUND

BLACK

WHITE

120 VAC POWER

WIRING W/ GROUND