Remote mode external signals, 9060 high voltage controller - installation, Local mode jumper settings – Ransburg 9060 HV Controller 80100-XXX User Manual

Page 30

9060 High Voltage Controller - Installation

25

CP-13-05.3

If a different switch is being used for the

trigger signal, read the switch documenta-

tion for the wiring instructions for the spe-

cific switching element. Verify whether

sinking or sourcing is to be used so the

local/remote trigger protection board

jumpers are set correctly. For further in-

formation, consult your authorized

Ransburg distributor for specific directions

pertaining to your installation or call Cus-

tomer Service.

N O T E

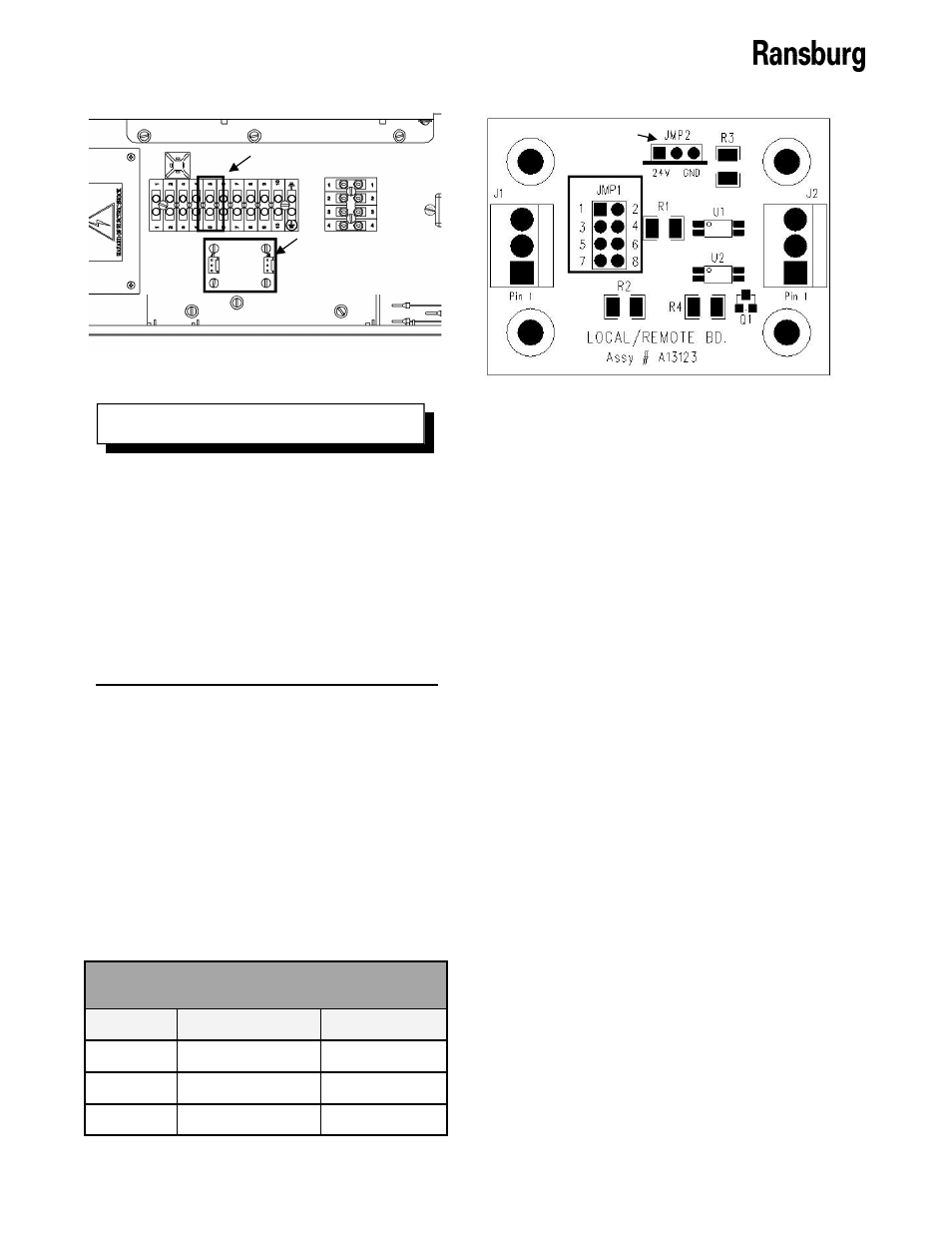

4. The local/remote board (Assy# A13123),

shown in Figure 14 at the bottom below the

remote I/O signal terminal block, is de-

signed for trigger protection in REMOTE

mode. It must have the jumpers adjusted

into “bypass position” to allow for LOCAL

mode operation for the desired input type.

The location of the jumpers on the board is

displayed in Figure 15. Use the LOCAL

mode jumper settings table for the jumper

settings based upon your specific input.

Figure 14: Remote I/O Signal Terminal Block

Trigger Signal - Position 5

Local/Remote Board

Jumper

Local Source

Local Sink

JMP1

1-3

1-3

JMP1

2-4

4-6

JMP2

2-3

1-2

LOCAL Mode Jumper Settings

Figure 15: Local/Remote Board Jumper Headers

Jumper 1

Jumper 2

5. Secure the cabinet door, replace the fuses,

and reconnect the AC source.

For any installation that includes a trigger signal

that is generated by a switch or source that is

external to the 9060 Controller unit, the signal

should be routed in through the standard I/O

connector using a shielded cable (supplied by

user). Secure the cable to the standard I/O

connector as described in “I/O Connections” in

the “Installation” section of this manual so that

the shield of the cable is connected to the

chassis of the enclosure.

REMOTE MODE

EXTERNAL SIGNALS

The REMOTE mode is designed for use with

automatic applicators such as the Estaquick

and Evolver SE where the control of the appli-

cator and Controller are driven by a external

control system using discrete analog and digital

I/O. For example, a programmable logic control-

ler (PLC), can be used as the control system.

There can be up to thirteen (13) or more signal

wires present depending on the signals that are

intended to be used by the control system.

More wires may be needed depending on the

number of power and ground lines required for

any particular installation.