Connection interface, Connectors, 9060 high voltage controller - introduction – Ransburg 9060 HV Controller 80100-XXX User Manual

Page 16

9060 High Voltage Controller - Introduction

11

CP-13-05.3

pressed with the reset button, at the same time,

the screen will display the resettable High

Voltage ON operating hours for 3 seconds on

the display screens.

Preset 2 Button

The Preset 2 Button (in the center below the kV

display) is used by itself to select “Voltage

Preset 2” in the LOCAL operating mode. If

pressed with the reset button, at the same time,

the screen will display the non-resettable High

Voltage ON operating hours for 3 seconds on

the display screens.

Preset 3 Button

The Preset 3 Button (to the right below the kV

display) is used by itself to select “Voltage

Preset 3” in the LOCAL operating mode.

Left (-)/Right (+) Buttons

The left(-)/right(+) buttons in the LOCAL operat-

ing mode are used to modify, decrease and

increase respectively, the currently selected

preset value. If the button is pressed and

released, the preset value is changed by 1 kV

at a time. If the button is held for over a 1/2

second, the value will begin changing by 5 kV

increments.

Reset Button

The reset button is used in LOCAL or REMOTE

operating mode to clear fault or overload

conditions when the trigger signal is OFF. This

will NOT prevent any other active fault condi-

tions from triggering a new fault.

HV Control Button

This button, shown in the center of Figure 3, is

not used

to perform mode changes.

It is

reserved

for future use. The unit defaults to

LOCAL mode. To enter REMOTE mode, a

remote I/O signal input, local/remote mode

selection, indicates when the unit should be in

REMOTE mode. When this remote I/O signal is

active, the unit will be in REMOTE mode,

otherwise the unit will be in LOCAL mode.

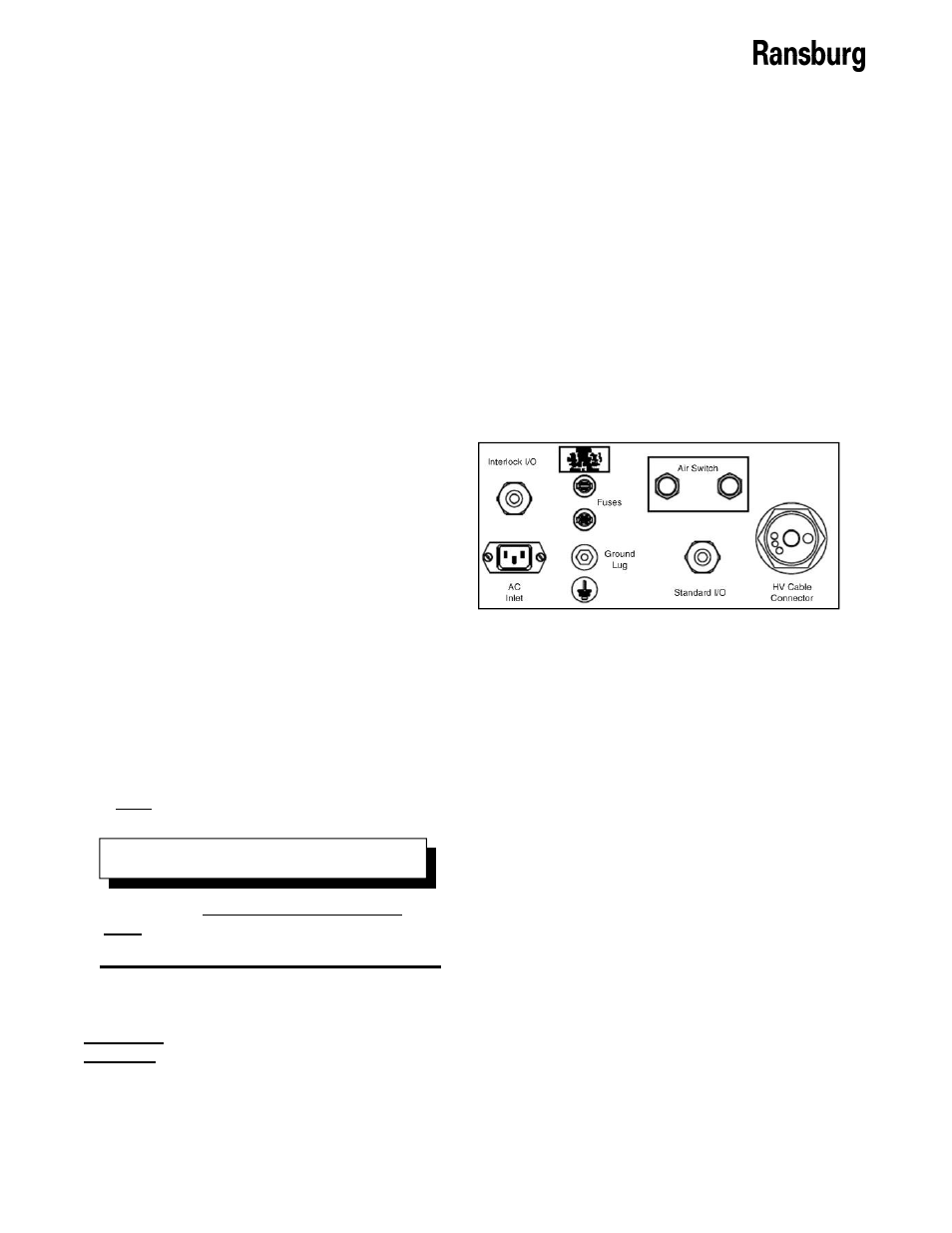

CONNECTION INTERFACE

The 9060 Controller connection interface shown

in Figure 4, provides all of the required connec-

tions for setting up either a remote I/O con-

trolled painting system or a local controlled

painting system. This connection interface

consists of one (1) high voltage cable connect-

or, one (1) standard I/O connector, one (1)

interlock I/O connector, one (1) ground lug

connection, one (1) optional air flow switch

connection, two (2) fuses, and one (1) AC inlet

receptacle.

Figure 4: 9060 Connection Interface

CONNECTORS

High Voltage Cable Connector

The high voltage cable connector is the largest

connector and is located on the far right of the

connection interface. The connector will come

covered with a factory installed red protective

cap. This connector is designed for use with

standard high voltage cables such as A10560,

79518, and 79519. The specific cable required

depends on the applicator being used. Please

refer to the applicator manual for the cable

required.

Standard I/O Connector

The standard I/O connector is located just left

of the high voltage cable connector. This

connector is provided as the entry point for a

shielded multi-conductor cable used for remote

I/O signals and includes the required cable

grommet hardware to keep the cable in place

with minimal strain. For more information on

remote I/O signal wiring, see the “Installation”

section of the service manual.

There is a 5 second fault reset delay

timer that inhibits the triggering of high

voltage immediately after a fault reset.

N O T E