Ransburg, Electric vs hydraulic disc reciprocator, Electric overhead reciprocator - introduction – Ransburg Overhead Electric Reciprocator ER-8100 User Manual

Page 10

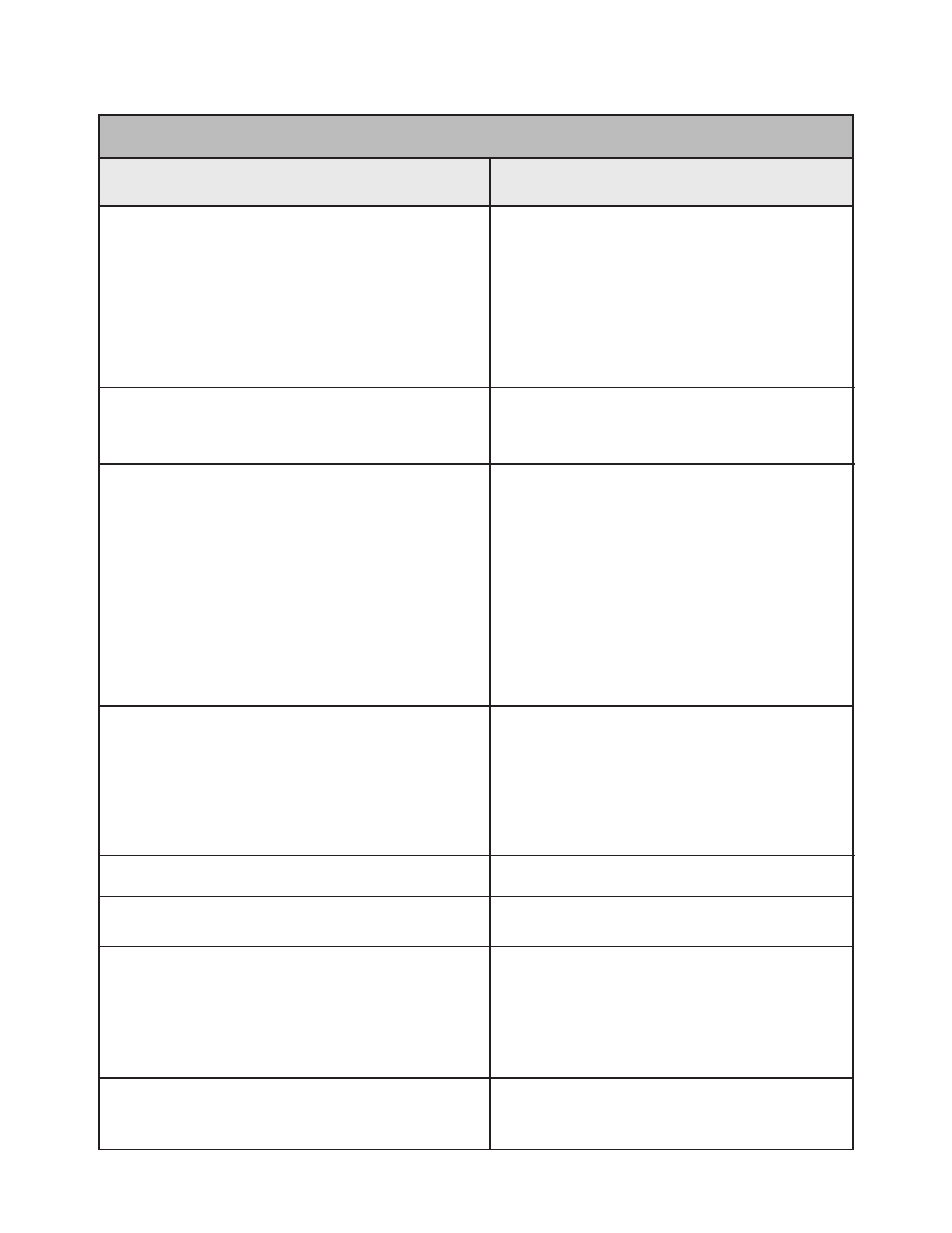

Electric Features

Electric Benefits

1. No hydraulic power supply

2. Counter balanced drive tube

3. 4 hp electric motor with vfd, closed-loop control,

heavy duty triple chain drive

4. Fail-safe breaking

5. Retrofitable drive package to hydraulic machines

6. Smooth operation

7. Easier installation

8. Improved product availability

• No potential for paint finish contamination

• Less noise

• No oil leaks

• No environmental issues relative to oil

contamination

• No routine filter / valve / seal maintenance

• No hoses or leaky connections

• Less maintenance

• Less floor space

• Energy efficient

• Enhanced acceleration / deceleration control

• Smooth operation

• Rugged / reliable

• Enhanced programmability via keypad with

display

• 10 programs

• Acceleration / deceleration control

• Accuracy ± 1mm

• Stroke and velocity adjustment “on the fly”

• Velocity to 5fps

• Zero back-lash

• Smooth, quiet operation

• Programmable hesitation up to 8 pts/program

• PLC option

• Friction brake locks drive tube in position in event

of chain failure

• “Run-away” limit switches shut down and lock

drive tube in event of controller failure

• Boost option

• Auto I/D option

• Analog output option

• Upgrades for older hydraulic reciprocators

• Improved control over paint film deposition

• Longer life

• Less floor space required

• No hosing / hydraulic tubing to run

• No oil fill / flush procedure

• No potential oil leaks

• No start-up issues due to contaminated control

valves, etc.

• No special order hydraulic cylinders

• All drive systems identical

ELECTRIC VS HYDRAULIC DISC RECIPROCATOR

7

Electric Overhead Reciprocator - Introduction

Ransburg

LN-9801-05.1