Maintenance, Ransburg, Troubleshooting guide – Ransburg LEPS5002 Power Supply for MicroPak User Manual

Page 17

TROUBLESHOOTING GUIDE

MAINTENANCE

>

Electrical shock hazard. ALWAYS turn

power to equipment OFF prior to cleaning

or servicing any part of the system. Fail-

ure to do so could result in serious injury

or death.

>

Whenever removing high voltage

cable(s) from equipment, ground the plug

end of the cable(s) by contacting the plug

to ground. Do not touch the plug until it

has been grounded. This will eliminate

the possibility of residual charge causing

electrical shock.

W A R N I N G

!

Periodically remove the high voltage cables and

make sure that they are clean, then reinsert into

the junction tank.

Make sure that the high voltage cables are fully

inserted into the junction tank and that the strain

relief connections are secure.

>

To assure continuous, efficient,

trouble-free operation of the LEPS5002

Power Supply and to extend its service

life, keep the exterior as clean and dry as

possible. It is also very important to keep

the areas around the high voltage cable

connections clean, to protect against con-

tamination when servicing the unit.

W A R N I N G

!

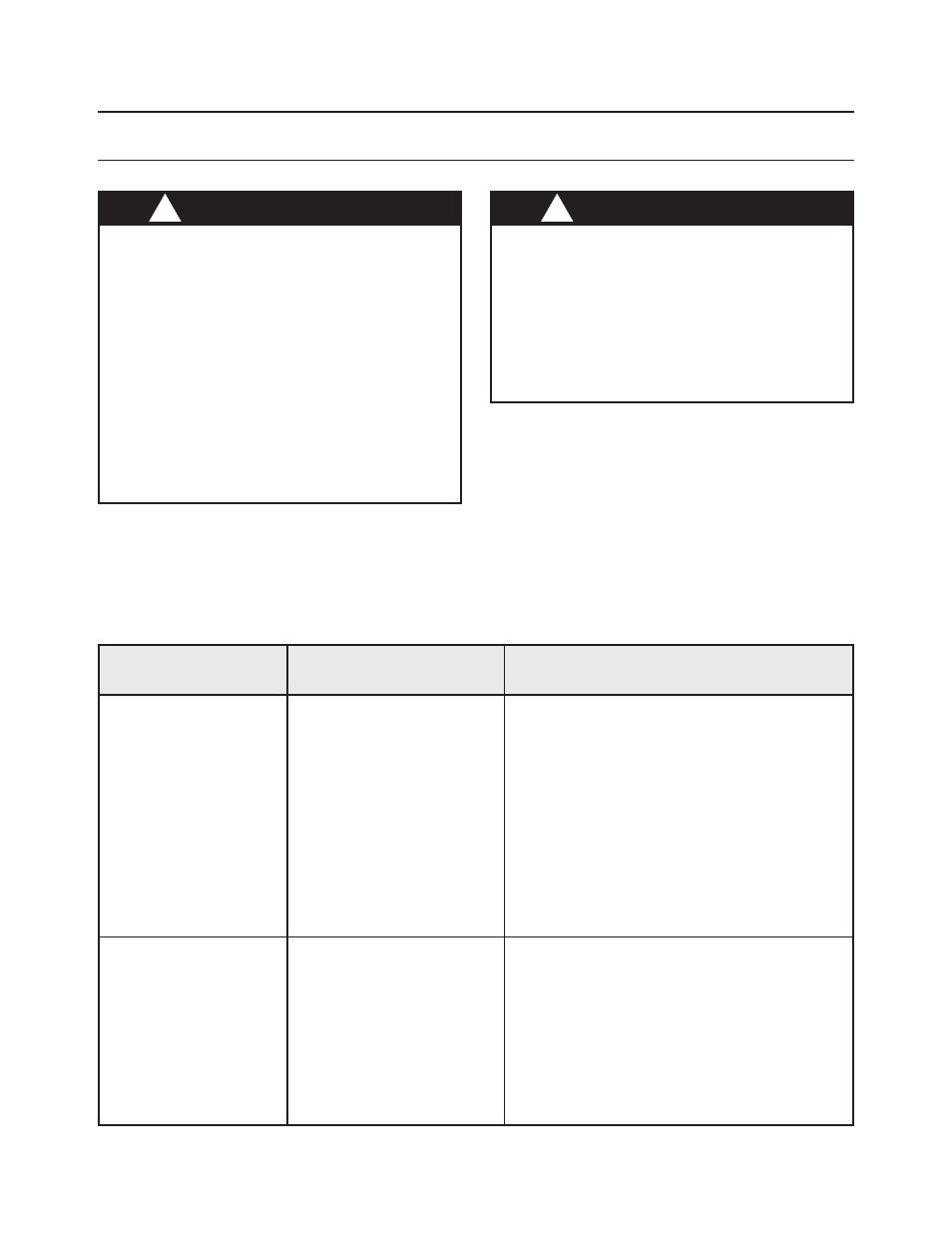

Figure 5: Troubleshooting Guide

General Problem

Cause

Solution

No High Voltage Output

(All Outputs)

No High Voltage

(Single Output)

1. Control unit bad or not

configured properly

2. Bad low voltage cable

or cable connections

1. HV cable not connect-

ed correctly

2. Bad high voltage elec-

trical contact or resistor

failure

1. Refer to the MicroPak service literature

for troubleshooting procedures.

2. Make sure that the low voltage cable,

74947, is plugged into the power supply

correctly and that the electrical contacts

are clean.

Make sure that all connections to the

MicroPak Control Unit are correct and

secured at terminal blocks.

1. Make sure that the HV input cable is

plugged into the junction tank and power

supply correctly.

2. Switch the HV output cable to an un-

used output if available.

LEPS5002 Power Supply - Maintenance

14

Ransburg

CP-98-02.3