Placement instructions, Connection instructions, Leak test – King Kooker 1203 Southwestern Sizzler User Manual

Page 13

plAcement InstructIons

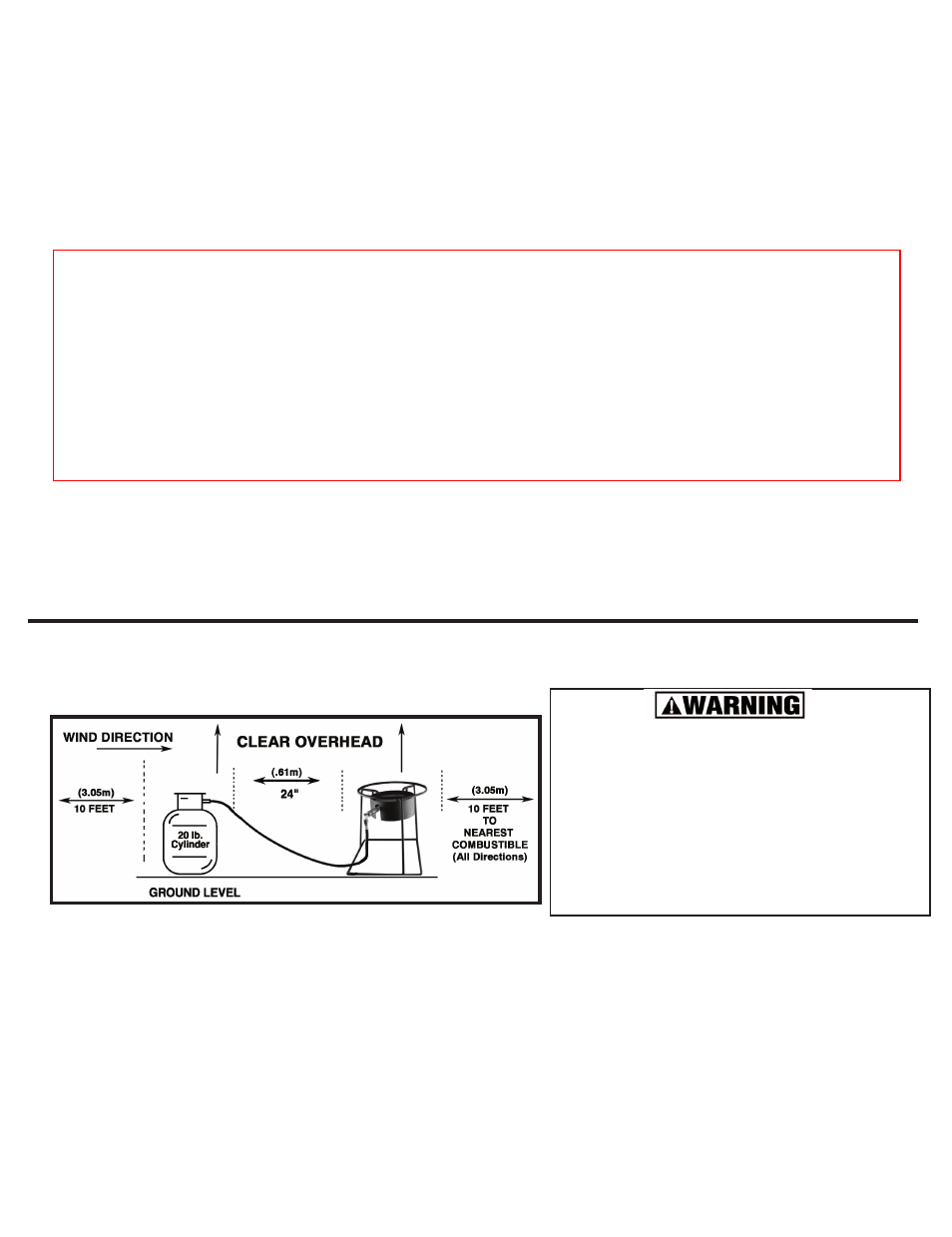

1. Never operate this appliance within 10ft. (3.05m) of any structure, combustible material or other gas

cylinder. Never operate this appliance within 25ft. (7.5m) of any flammable liquids or vapors.

2. There must be no combustibles or roof overhead.

3. Keep 24 inches (.61m) of space between the LP gas cylinder and the appliance.

4. The LP gas cylinder and appliance must be located so that any wind is blowing the heat of the

appliance away from the propane cylinder. This also helps fire prevention by blowing the flames of

a grease fire away from the propane cylinder.

5. Center the pot over the burner on the cooker. Do NOT use any pot larger than 30 quarts (28.39

liters).

13

Keep 24 inches (.61m) between the cylinder and

the appliance. Placing the cylinder too close to the

appliance could result in fire or explosion which could

cause property damage, personal injury or death.

The hose connecting the appliance to the tank poses a

trip hazard. Do not step over the hose or walk between

the cylinder and appliance. Tripping could cause the

appliance or cylinder to tip over, leading to fire or

explosion which could cause property damage, personal

injury or death.

connectIon InstructIons

1. Check that your hose assembly valve is set to not allow gas flow. Turn the manual valve clockwise

until it stops. This is the OFF position.

2. Attach the regulator to the cylinder valve by turning the Type 1 fitting clockwise. Hand tighten.

Refer to the hose connection diagram for the appliance on page 10.

3. Perform the Leak Test:

4

. Before lighting the cooker, check that the venturi tube is free of obstruction and that the orifice is

properly threaded into the venturi tube as per the instructions on page 10. Both situations must

be corrected if necessary before lighting to prevent flashback.

leAK test

Before lighting the appliance, a thorough leak test must be satisfactorily completed using

a non-ammonia soapy water solution (50% non-ammonia soap and 50% water). This is to be

applied with a small brush to all gas joints after the cylinder valve is opened (no more than

1/2 turn). If bubbles are seen, indicating a leak, turn off the cylinder and tighten the leaking

connection until a further leak test shows no leaks.

If tightening the connection does not stop the leak, call Metal Fusion, Inc. (800) 783-3885,

for assistance.

neVer use hose/regulAtor Assembly IF leAKIng.