Sh series, General pump – General Pump SH User Manual

Page 8

GENERAL PUMP

A member of the Interpump Group

SH SERIES

Page 8

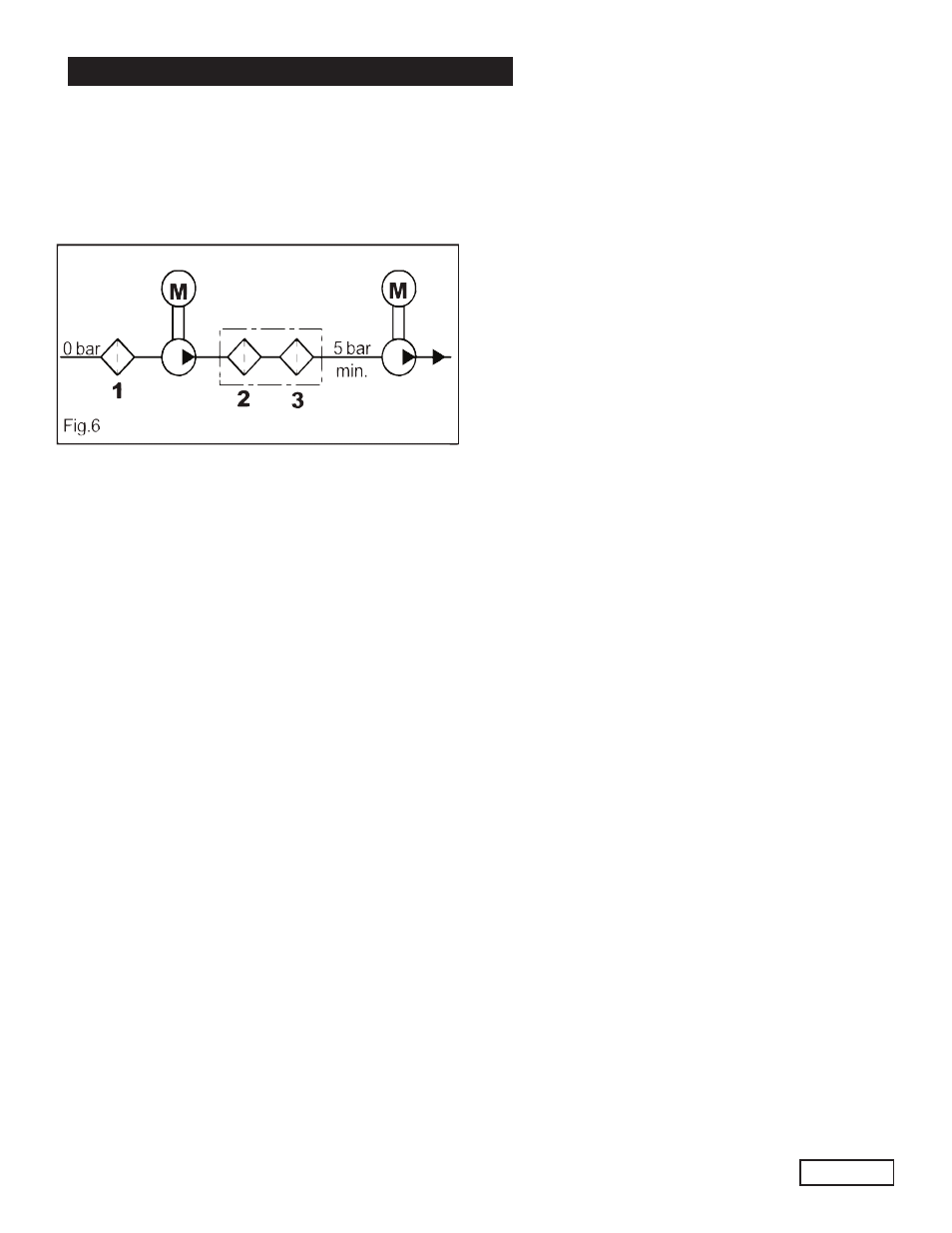

9.5 Filtration

SH pumps require 10 to 20 microns water filtration degree.

For a correct filtration system three individual

filter units should be provided and positioned as shown

in Fig. 6.

The filters should be installed as close as possible to the

pump, allow easy inspection and have the following

specifications:

a. Capacity of each filter should be at least three times

the rated pump flow rate.

b. Filter port diameters should not be smaller than the

pump inlet ports.

c. Filtration degree of each filter should be as follows:

Filter 1: 250 microns

Filter 2: 70 - 100 microns

Filter 3:

10 - 20 microns

IMPORTANT NOTE: in order to properly safeguard the

pump it is very important to plan cleaning of the filter

with a frequency depending on the water quality,

filtration degree and number of hours of each

application.

9.6 Delivery line

For a correct delivery line comply with the following

instructions:

1. The first length of delivery hose should be flexible in

order to isolate the pump vibrations from the

rest of the system.

2. Use only high pressure hoses and fittings able to

guarantee the largest possible safety margins in

any working conditions.

3. A suitable relief valve should be installed in the

delivery line.

4. Use glycerine filled pressure gauges, as the most

suitable for pulsating loads.

5. When designing the delivery line, take into proper

account the unavoidable drop in pressure, due to

its length and size.

10. START UP AND RUNNING PROCEDURES

10.1 Before start up

Before start up make sure that the following conditions

have been complied with:

1. Suction line should be connected: the pump must

never run dry.

2. Suction line must be perfectly air-tight.

3. Any ON-OFF valve in between the pump and water

source should be open and make sure the water

gets into the pump freely.

4. Set the pressure line in dump mode in order to let

the air in the pump get out easily thus facilitating

the pump priming.

5. Make sure all suction/delivery line connections are

fully tightened.

6. Joint alignment, belt tightening and PTO shaft

inclination tolerances should remain within the

values indicated by the transmission Manufacturer.

7. Make sure the oil level is correct.

Note: in case the pump has not run for a long period of

time check the suction and delivery valves for scaling

(see paragraph 11.2).

10.2 Starting up

1. Pump and motor/engine should start offload, set the

regulating valve to zero or set the pressure line in

dump mode by means of proper dumping devices.

2. Make sure the pump starts only when the correct

inlet pressure is provided.

3. When starting the pump up for the first time or after

every wiring re-connection check for the proper

direction of rotation.

4. Check that the rotating speed does not exceed the

rated value.

5. Before putting the pump under pressure let it run for

some time until the oil flows freely.

6. Before stopping the pump release the pressure from

the system by operating the dump device or by

releasing the regulating valve and reduce RPM to a

minimum (diesel applications).