Farm Star MP-214 User Manual

Page 10

9

14

O P E R ATING INSTRUCTIONS

(continued)

T R O U B L E S H O O T I N G G U I D E

(continued)

A D J U S T M E N T S

(continued)

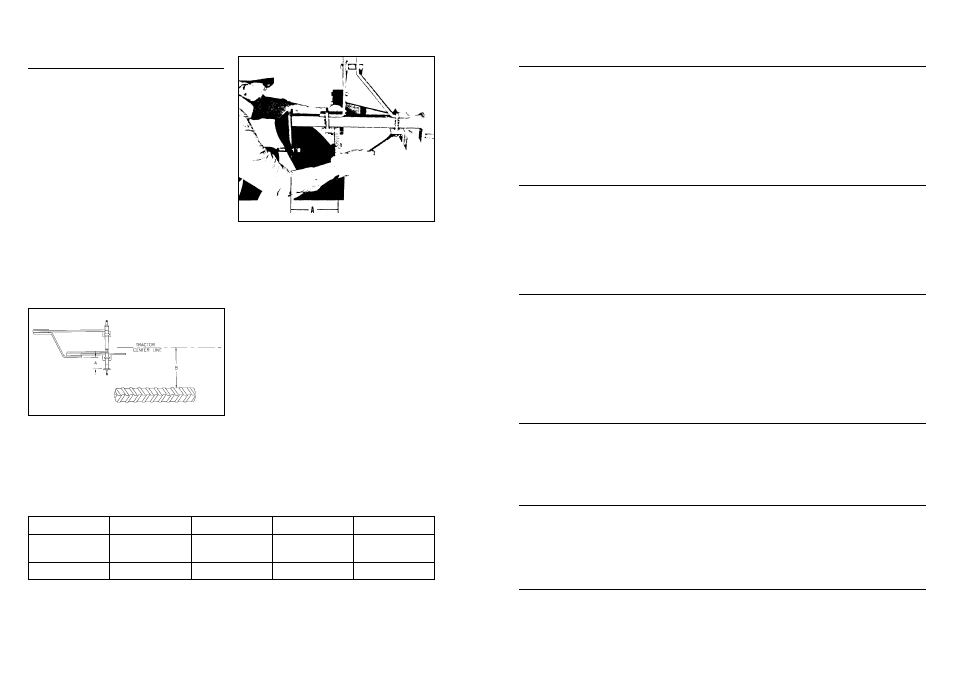

In order to trail properly with a minimum effect on

tractor steering, it is necessary to adjust the plow so that

the plow is pulling as close to the tractor centerline as

possible. Refer to Table 1 and Figures 1 and 2, dimen-

sion A. Note that for one bottom plows in particular, the

ideal wheel tread width is too narrow for most tractors to

obtain. In those cases, set the width as narrow as

possible.

1) Do not attempt to lift heavy parts or assemblies. Use

a hoist, crane, forklift, or similar safe mechanical device.

2) Preview the plow instructions and the exploded views

in your operator’s manual and become familiar as to how

the parts or assemblies go together.

3) Have good blocking material available.

4) Select an area for adjustment that is clean, free from

debris, and fairly level.

COULTER ATTACHMENT

Rolling coulters are recommended to make plowing

smoother and neater. Coulters also make plowing easier

by reducing drag.

Mount the coulter assembly on the beam in front of the

plow bottom. On the one bottom 14” plow, it can only go

on the left side of the beam. On the two bottom 14” plow,

it can be mounted on either side of the beam to aid in

lateral adjustment.

1) Remove the U-bolt and clamp components from the

coulter stem.

2) Install the U-bolt through the plow beam.

3) Seat the coulter stem in the clamp and position the

U-bolt. Install lockwashers and nuts but do not tighten.

4) For hard ground conditions, raise it to reduce its

tendency to ride the plow out of the ground. For light and

loose soils, especially where there is much trash, move

the coulter down.

Cross Shaft and Wheel Tread Settings - See Table 1

(Two Bottom Plow frame shown)

* Measure from inside of the tires to the centerline of pull.

Cross Shaft Assembly and Adjustment

(One Bottom Plow shown)

Measure from the inside of the tires

——— ———

to the centerline of pull.

TABLE 1

FIG. 1

FIG. 2

Model

Cross Shaft

Cross Shaft Setting

Ideal Pull Point *

Tire Tread

(Dimension “A”)

(Inside of Tires)

1 bottom 12”

Cat. O (20”)

9

1

/

2

”

9”

18”

1 bottom 14”

Cat. I (26”)

11

1

/

2

”

10

1

/

2

”

21”

2 bottom 14”

Cat. I (26”)

7

1

/

4

”

17

3

/

4

”

35

1

/

2

”

P R O B L E M

P O S S I B L E C A U S E

P O S S I B L E R E M E D Y

Plow ridging.

1. Front bottom too deep.

2. Front bottom too shallow.

3. Front bottom cutting too wide or

too narrow.

4. Coulter Adjustment.

Shorten right-hand leveling screw or lengthen

tractor top link.

Lengthen right-hand leveling screw or shorten

tractor top link.

Adjust plow properly by correct wheel and

cross shaft settings.

Properly adjust coulter. See COULTER

ADJUSTMENTS.

Poor trash cover-

age.

1. Coulter adjustment.

2. Dull coulters.

3. Coulters not turning.

4. Bottoms not scouring.

Set coulters deep enough to cut trash but not

deep enough to push trash.

Sharpen or replace blade.

Worn or binding hub bearings – replace bear-

ings.

Clean bottoms frequently until land polish is

obtained.

Bottoms won’t

scour.

1. New bottoms.

2. Plow running on nose.

3. Plow running crooked.

Clean surfaces with kerosene or fuel oil.

Lengthen top link.

Place the right-hand link pin in the cross

shaft’s center adjustment hole. Obtain the

proper width of cut for front bottom at this set-

ting by making cross shaft and tractor wheel

adjustments. The wheel track should be

adjusted so that the inside of the right-hand

front tire is in line with the inside of the right-

hand rear tire.

Ragged furrow

wall.

1. No coulter.

2. Coulter adjustment.

3. Plow running crooked.

Add coulter.

Set coulters to run more toward land and

deeper if in loose soil. Be sure coulter swings

freely.

See BOTTOMS WON’T SCOUR.

Plow pulls heavy.

1. Plow running on nose.

2. Bottoms not scouring.

3. Excessive landside pressure.

Lengthen top link.

See BOTTOMS WON’T SCOUR.

Incorrect tractor wheel or cross shaft setting –

Rear landside should run approximately

1

/

4

to

1

/

2

” from furrow wall.