Farm Star FC-9 User Manual

Page 6

4

5

I N S T R U C T I O N S

(continued)

O P E R AT I O N

The designed and tested safety of this machine

depends on it being operated within the limitations as

explained in this manual. Be familiar with and follow all

safety rules in the manual, on the implement and on the

tractor.

The safe operation of this machine is the responsibility

of the owner / operator. The operator should be familiar

with the field cultivator and tractor and all safety prac-

tices before starting operation. Read the safety rules.

Never let anyone stand between the rear of the tractor

and the implement while the tractor is backing up to

connect to the implement. Always stand to the side until

tractor has come to a complete stop and the brakes set

or the tractor shift placed in “PARK”.

Attaching the field cultivator to the tractor increases the

overall length of the working unit. Allow additional

clearance for the implement to swing when turning.

Check for ditches, stumps, holes, or other obstacles

that could upset tractor or damage cultivator.

For proper operation, level the field cultivator by adjust-

ing the tractor linkage. This will assure that the cultivator

will run level.

The tractor 3 pt. hydraulic lift system should be set to

transfer most of the field cultivator’s weight and draft to

the tractor to maximize traction (There may not be a 3 pt.

Draft control on some small or older tractors – Refer to

Tractor Owner’s Manual.)

Set hydraulic lift control arm stop for the operating

depth.

The deeper you operate the cultivator, the more tractor

horsepower and traction will be required.

In very hard soil or in dry conditions (or with a small

tractor), it may not be possible to operate the cultivator at

the desired depth. In these cases, it may be necessary to

make several passes. (Increase the depth with each

pass until the desired depth is reached.)

The best “shattering” action will be realized at forward

speed of 2

1

/

2

to 4 miles per hour. It is not recommended

to exceed 5 MPH as it will only increase fuel consump-

tion, horsepower required, and wear on the tractor and

implement.

NOTE: Do not make turns with the field cultivator in the

ground. Damage to cultivator will occur. Always raise

implement and lower after turn is made.

Do not attempt to operate the field cultivator when soil

is wet. Wet soil will not shatter or break up and you will

compact the soil.

It is suggested that when you make several passes

across a field that you operate the field cultivator diago-

nal to the direction of the first pass.

The points of the field cultivator are reversible. When

the first point wears back, remove the bolts, reverse the

point and reinstall the bolts.

Do not let the point wear back so far that wear occurs

on the lower shank body.

I N S T R U C T I O N S

T R A C T O R R E Q U I R E M E N T S

A N D P R E PA R AT I O N

The model FC Field Cultivators can be used on both

Category I tractors (30 hp and larger) and Category II

tractors.

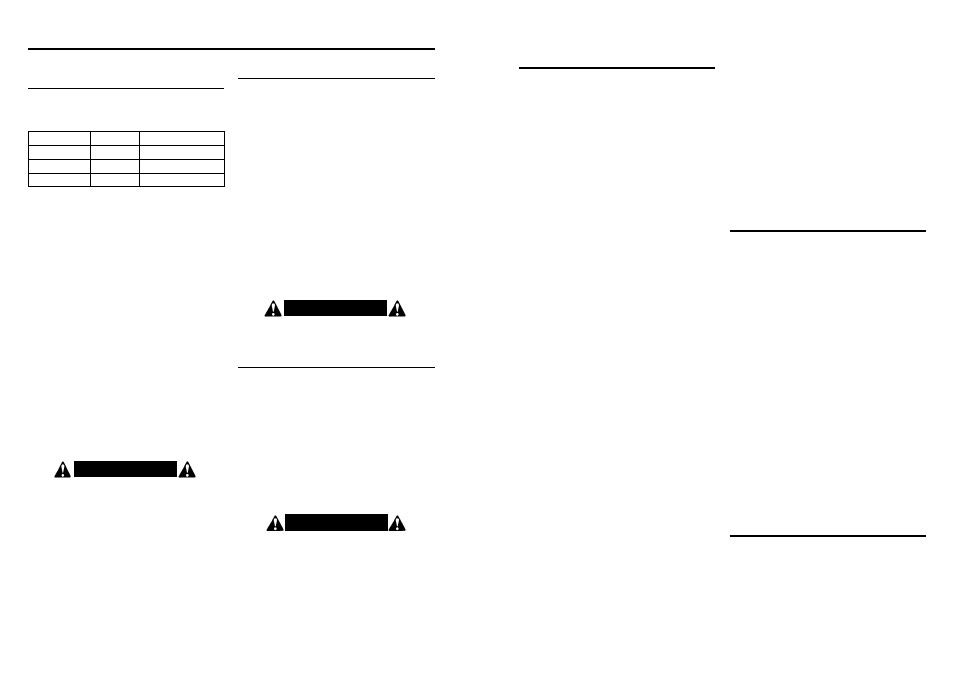

Model

# Shanks

Approx. H.P. Req.

FC-5

5

30 - 35

FC-7

7

35 - 45

FC-9

9

45 - 60

The operator is responsible for the safe operation of the

implement. The operator must be properly trained.

Operators should be familiar with the implement and

tractor and all safety practices before starting operation.

Read all safety rules.

Be sure tractor is in good condition. Read all the

safety precautions and make sure all tractor

operators are familiar with the safety rules of

operation.

C A U T I O N !

Read manual before operating.

C A U T I O N !

•

Know your controls and how to stop tractor and

engine quickly in an emergency. READ THIS

MANUAL AND THE ONE PROVIDED WITH YOUR

TRACTOR.

•

To avoid accident or injury, do not allow anyone to

operate this equipment without proper instructions.

Any person who operates this equipment must be

instructed in and be capable of the safe operation of

the tractor implement and all controls.

•

Do not allow children to operate this machine.

S A F E T Y T R A I N I N G

W A R N I N G !

A heavy load can cause instability in driving a

tractor. Make sure the front of the tractor is properly

counterbalanced with weights. Always drive slowly -

especially around turns. An unstable tractor could

steer badly and possibly tip over, causing injury or

death.

NOTE: Actual horsepower required will depend on type

of soil, operating depth, soil moisture, and operating

speed.

It is recommended that only tractors with wide front

axles be used with this implement. Tricycle front wheel

arrangements are inherently unstable and tractor roll-

over accidents are more likely to occur.

The tractor also needs lift arm stabilizer bars or sway

blocks to control side movement of the implement.

Check the tractor’s 3 pt. hydraulic system. Refer to your

tractor operator’s manual or dealer for any adjustments

necessary to put the hydraulic system in good working

order. (I&T shop manuals will list most specifications and

adjustment instructions – available from most farm

equipment dealers.)

Be sure tires and rims are in good condition. Inflate tires

to the proper recommended air pressure.

It is recommended that a ROPS (Roll-Over Protection

Structure) and a seat belt be installed on all tractors.

Contact your local dealer for a ROPS for your tractor.

Refer to the repair parts drawing in this manual to get

an idea of how the parts need to be assembled for each

individual implement model.

The holes in the frame angle will allow the shanks to be

located at different spacing.

NOTE: All shanks must be symmetrically spaced.

Insert the draw pins into the ball sockets in the lower lift

arms of the tractor 3 pt. hitch. Lock in place with linch

pins (not furnished.)

Attach the mast of the 3 pt. main frame by installing the

tractor center link (toplink) with a toplink pin (not

furnished.)

Adjust the toplink assembly to obtain the correct angle

of the implement. Check the tractor 3 pt. lift arms and

adjust to level the implement from side to side.

A S S E M B LY A N D M O U N T I N G

1. Check all nuts and bolts and make sure they are tight.

2. Check points for wear and damage. Replace when

necessary.

3. Grease shank bushings each 30 working hours.

M A I N T E N A N C E

T R O U B L E - S H O O T I N G

PROBLEM: Tractor will not pull implement

1. Insufficient horsepower – Use larger, heavier tractor.

2. Soil too wet – Let soil dry.

3. Soil too hard and dry – Wait for rain.

4. Points too dull – Replace points.

5. Insufficient traction – (See tire slippage below)

6. Attempting to operate too deep – Reduce depth set-

ting and make several passes, gradually increasing

depth.

PROBLEM: Excessive tractor tire slippage

1. Tractor too small – Use larger, heavier tractor.

2. Insufficient traction – Dual rear tire or add ballast,

increase draft control, operate at shallower depth.

3. Operating too deep – See #6 above.

PROBLEM: Excessive point wear

1. Soil too dry – Wait for rain.

2. Abrasive soil – Consider having points hard surfaced

by local welder.

3. Operating too fast – Reduce forward speed.