Instructions – Farm Star 500 W User Manual

Page 5

T

T R

R A

A C

C T

T O

O R

R R

R E

E Q

Q U

U I

I R

R E

E M

M E

E N

N T

T S

S

A

A N

N D

D P

P R

R E

E P

P A

A R

R A

A T

T I

I O

O N

N

The Model 500 3-pt. mounted post hole digger will fit most

Category I, Category II and some larger Category 0 tractors

equipped with a standard 3-pt. hitch.

NOTE: Some Category 0 tractors have very short lift arms or

5

/

8

” diameter (Cat. 0) lift arm ball ends. These tractors are not

usually suitable for post hole digging operation.

Check the tractor’s 3-pt. hydraulic lift system. It should oper-

ate up and down smoothly and have enough power to lift the

dirt-loaded auger out of the hole. Refer to your tractor opera-

tor’s manual or dealer for any adjustments necessary to put the

3-pt. hydraulic lift system in good working order. (I&T shop

manuals will list most specifications and adjustment instruc-

tions - available from most farm equipment dealers.)

Check the shield over the PTO stub shaft. Make sure it is in

good condition and bolted securely to the tractor. Purchase a

new shield if old shield is damaged or missing.

Tractor must be equipped with stabilizer bars, adjustable sway

chains, or sway blocks to keep the post hole digger from swing-

ing side to side.

Smaller size tractors may need front counter weights to

counter-balance the weight of the post hole digger and the

weight of the dirt on the auger.

It is recommended that the tractor be equipped with a

Rollover Protection System (ROPS) and a seat belt that is

used.

Be sure your tractor is in good condition. Read all the

safety precautions and make sure all tractor operators are

familiar with the safety rules of operation.

A

A S

S S

S E

E M

M B

B L

L Y

Y A

A N

N D

D M

M O

O U

U N

N T

T I

I N

N G

G

Unpack all the bundles and lay out various parts. Start with

the yoke (Ref. #4). Place the pull pins (Ref . #5) through the

holes in the legs of the yoke and secure with nuts and lock

washers.

NOTE: If your tractor lift arm spacing is 32”, place the pull pins

on the outside of the yoke legs as shown in the diagram. If your

tractor lift arm spacing is 26” or less, then place the pull pins

on the inner side of the yoke legs. The pins are Category I (

7

/

8

”

dia.). If your tractor is Category II, then lift arm bushings are

required to properly fit the 1

1

/

8

” dia. Cat. II lift arm balls.

(Bushings not supplied.) Place the lift arms of your tractor over

the pull pins in the yoke and secure with linchpins (not sup-

plied).

Pin end of digger boom (Ref. #1) to tractor toplink bracket.

Raise boom by hand – check that it doesn’t hit any part of

toplink bracket (some tractors only). If problem exists, change

hole location and re-check. Failure to check can result in

boom damage. Cat. I tractors need bushing. Connect yoke to

boom with pin (Ref. #13) and cotter pins.

7

4

INSTRUCTIONS

C A U T I O N !

NOTE: Always use adapter bushings when using Category I

pins on a Category II hitch. Trying to use Cat. I pins in a Cat.

II hitch without bushings will result in a very sloppy fit and the

post hole digger will be unstable.

NOTE: When attaching the yoke to the boom, use the hole in

the adjustment channel best suited for your tractor. If you don’t

know the best hole location, start with the middle hole.

Install shields on input and output ends of gearbox. A socket

with a long extension is the best tool for easy installation. The

shield with two large holes (Ref. #22) is for the output end of the

gearbox. Check exploded parts drawing for correct position.

NOTE: It is easier to install the guards on the gearbox before

installing the gearbox on the post hole digger.

Do not operate this equipment without shields properly

installed. This is for your protection, and the manufactur-

er recommends the use of these shields at all times while

operating this post hole digger.

Attach the gearbox (Ref. #14) to the boom using the gearbox

hitch pin (Ref. #13) and secure it with the two cotter pins (Ref.

#7). The gearbox should be placed so that the large shaft is

pointing toward the ground and the small shaft is pointing

toward the tractor.

NOTE: The gearbox is shipped WITHOUT lubricant, so it will

be necessary to fill it before use. With the gearbox in a level

position, fill to the side inspection hole with a good 90 wt. gear

lubricant. Check often and add lubricant if necessary.

Grease the input shaft of the gearbox before installing the

PTO shaft. This reduces the chance of the PTO shaft yoke

from galling to the input shaft if the shear pin should break.

Slip the two telescoping ends of the PTO shaft together.

Place the unsplined end on the gearbox input shaft and bolt it

in place with the

5

/

16

” shear bolt (Ref. #15) and secure it with the

lock washer and nut.

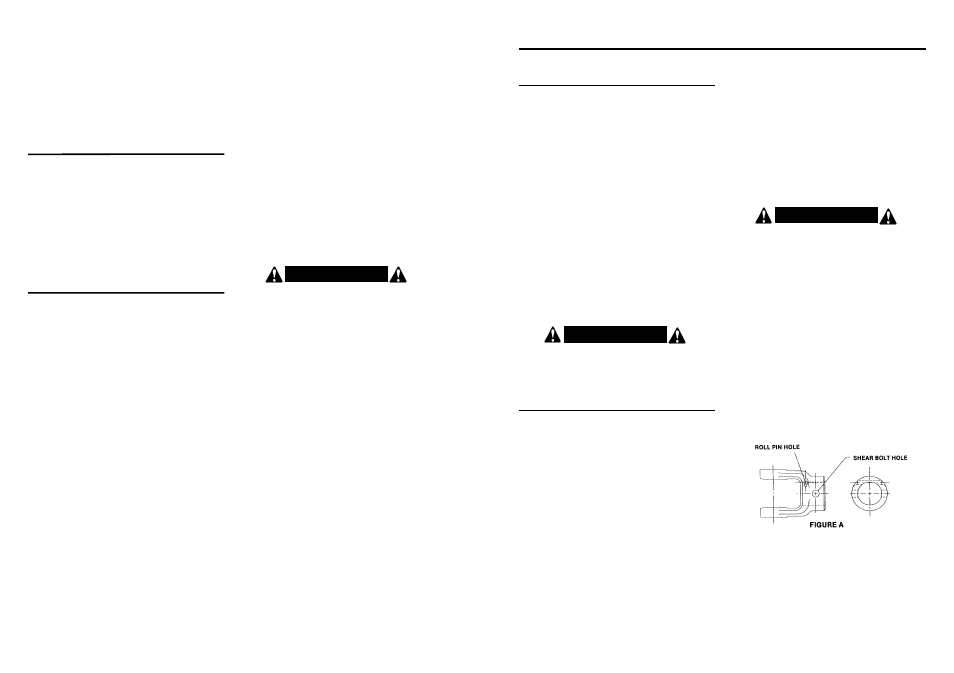

On the implement end or the PTO shaft there is a hole in the

yoke just forward of the

5

/

16

” shear bolt (see Figure A). This hole

is for the

3

/

16

” diameter x 1

1

/

4

” long roll pin (#2504011). When

this roll pin is driven in this hole, the center of the roll pin

engages into the groove on the front of the gearbox input

shaft. This prevents the PTO assembly from coming off if

C A U T I O N !

3. Universal joints should be greased after digging 150 holes.

Telescoping parts must be kept clean and lubricated.

4. Check bolts and pins daily. Check auger teeth and teeth

mounting bolts more often if digging in rocky soil conditions.

5. Make sure PTO driveline yoke and gearbox input shaft are

clean and free of burrs. Keep well lubricated to prevent

galling of yoke and input shaft when shear bolt becomes

sheared.

6. Keep all shields in place. Order new shields if damaged or

missing.

7. Keep cutting edges sharp. Sharp cutting edges dig easier

and better. Outer cutting edges on larger augers wear

faster than inner cutting edges; switching teeth will even

wear.

P

P O

O S

S T

T H

H O

O L

L E

E D

D I

I G

G G

G E

E R

R O

O P

P T

T I

I O

O N

N S

S

1. Heavy Duty Augers: Augers with heavier flighting and a

reinforced drive tube are available for rocky or tough soil

conditions. Check with dealer for availability.

2. Heavy Duty Fishtail Center Point: Recommended for

tough or rocky soil conditions. The fishtail point will work

around smaller rocks. Order part #170802.

3. 12” Auger Extension: Available for situations where deep-

er holes are required. NOTE: Smaller tractors may not

raise auger high enough to clear hole when 12” auger

extension is used. Order part #170700.

4. Hydraulic Down Force Kit: For tough, hard soil conditions.

This will allow operator to put 300-400 lbs. of down force on

the auger to force cutting edges into tough or hard ground.

Tractor must have auxiliary hydraulic outlet. Order part

#170810 for Model 500 Post Hole Diggers.

T

T R

R O

O U

U B

B L

L E

E -

- S

S H

H O

O O

O T

T I

I N

N G

G G

G U

U I

I D

D E

E

PROBLEM: AUGER WILL NOT DIG

Possible Solutions:

• Teeth dull - sharpen or replace.

• Ground too dry and hard - order optional fishtail point

(#170802) or optional down force kit, or wait until it

rains.

• Auger turning too fast and bouncing - reduce speed.

• Tall grass has wrapped around auger teeth - remove.

• Auger encountering rocks, roots, or other obstruction -

lift auger from hole and inspect.

• Auger teeth improperly positioned - see operator’s

manual for proper tooth pattern.

PROBLEM: AUGER DIGS SO FAR, BUT WILL NOT

DIG DEEPER

Possible Solutions:

• See solutions for #1 above.

• PTO assembly “bottoms out,” not allowing digger to

lower - remove auger from digger and lower digger.

Gearbox should lower to the ground; if not,PTO drive-

line assembly may need to be shortened.

• PTO driveline interferes with swinging drawbar - swing

drawbar out of the way or remove.

• Tractor hydraulic system may be faulty - consult tractor

dealer.

• Soil could have hardpan layer 6”-10” below surface -

use optional fishtail point (#170802) or optional down

force kit (see list of optional equipment).

PROBLEM: POST HOLE DIGGER SWAYS SIDE TO

SIDE

Possible Solutions:

• No sway bars or sway blocks on tractor- add same.

• Lift arms not adjusted evenly - adjust lift arms.

• Post hole digger is mounted with excessive looseness

in the hitch connecting points - use proper size pins or

bushings

.

PROBLEM: BENT AUGER FLIGHTING OR BENT

AUGER

Possible Solutions:

• Tractor moved while auger was turning in hole -

always set brakes on tractor and make sure it is out

of gear.

• Operator moved tractor with auger in hole to try and

straighten a hole being dug at an angle.

• Auger is encountering rocks or roots or other foreign

objects - remove object from hole or change location.

• Outer edge of auger flighting is bending due to contact

with rocks or roots - use heavy duty auger with thicker

flighting.

• Shear bolt has been replaced with harder bolt - replace

with Grade 2 bolt per instructions.

PROBLEM: AUGER SCREWS ITSELF INTO THE

GROUND

Possible Solutions:

• Operator did NOT ease 3-pt. hitch to ground slowly.

• Faulty 3-pt. hitch hydraulic system on tractor.

• Draft control is not in OFF position.

• Tractor is too small to handle digger.

PROBLEM: PTO DRIVELINE ASSEMBLY COMES

OFF INPUT SHAFT OF GEARBOX WHEN

SHEAR BOLT IS SHEARED.

Possible Solution:

• Roll pin missing in yoke at gearbox input shaft. Install

roll pin as per instructions.

THIS IS A DANGEROUS SAFETY HAZARD, CORRECT

IMMEDIATELY!

PROBLEM: PTO DRIVELINE FAILURE

Possible Solutions:

• Operator raising post hole digger too high above

ground when PTO is engaged - causes excessive PTO

joint operating angle.

• PTO is engaged while moving between holes. (Auger

swings, which causes excessive PTO joint operating

angle.)

• Improper use of a hard shearbolt - use Grade 2 bolt per

instructions.

• Driveline has not been properly lubricated.

• Engaging tractor PTO with engine at high rpm.

• Digging holes too deep so that PTO driveline contacts

ground.

• Operating at high rpm.

• Use of auger extension can require post hole digger to

be lifted high, which can cause excessive PTO joint

operating angle.

PROBLEM: PTO DRIVELINE “GALLS” OR “FRIC-

TION WELDS” TO INPUT SHAFT OF

GEARBOX

Possible Solution:

• No lubrication on input shaft of gearbox to allow yoke

of PTO driveline to turn freely on input shaft when

shear bolt is sheared.

Always keep input shaft

greased.

PROBLEM: GEARBOX FAILURE

Possible Solutions:

• No oil in gearbox.

• Oil not changed per instructions.

• Shear bolt has been replaced with a harder bolt -

replace with Grade 2 per instructions.

• Bent output shaft is due to operator moving tractor

when auger is in hole

.

W A R N I N G !