Cable inspection guide – Direct Lift PP8S User Manual

Page 20

20

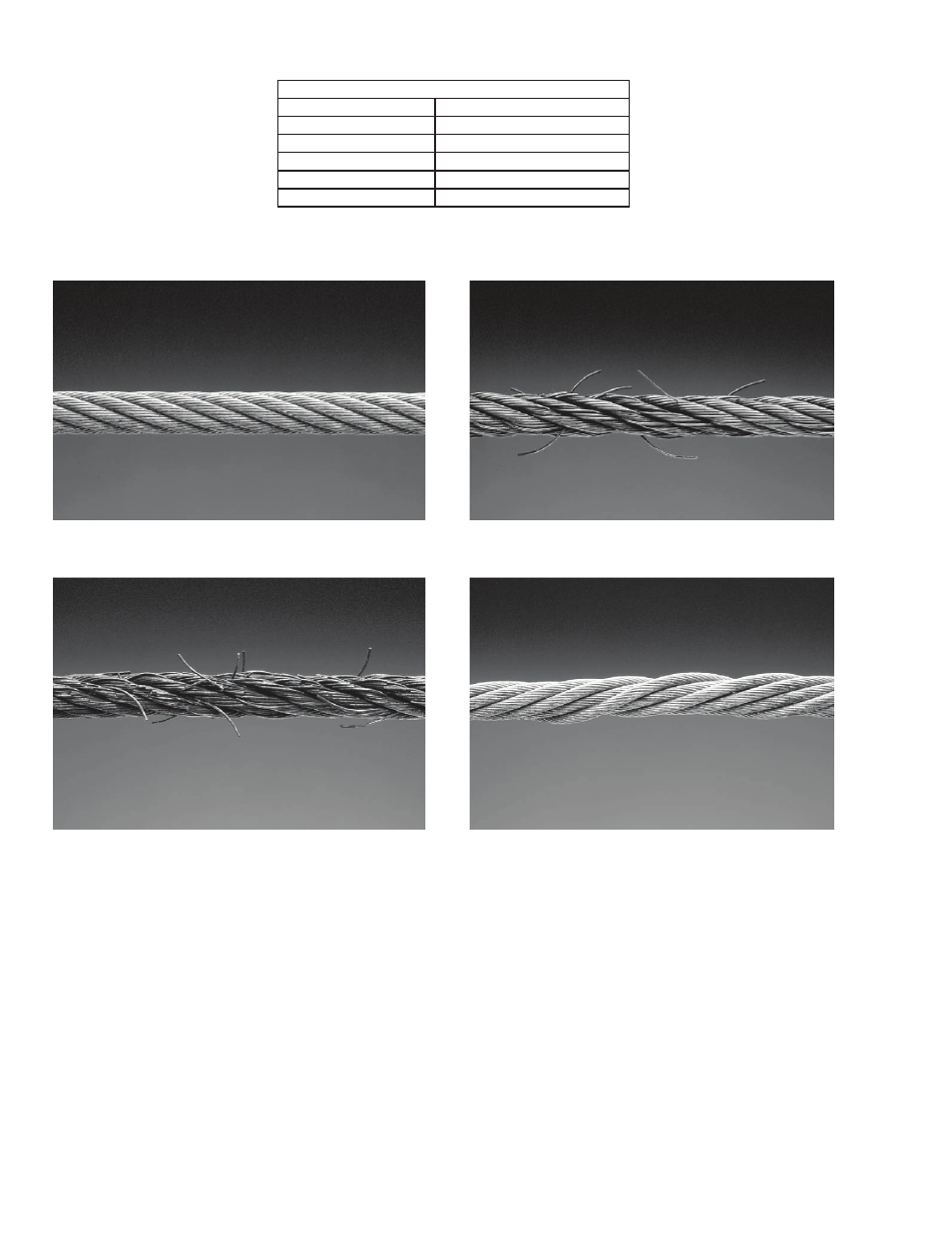

Cable Inspection Guide

Maximum Allowable Cable Necking

Nom. Cable Diameters

Max. Reduction in Diameter

Up to 5/16”

1/64”

3/8” to 1/2”

1/32”

9/16” to 3/4”

3/64”

7/8” to 1-1/8”

1/16”

1-1/4” to 1-1/2”

3/32”

Typical Good Cable

Cable With Broken Wires

Cable With Severe Corrosion

Cable With Necking

Daily Inspection & Maintenance

1. Cleanliness: Cables, Columns, Runways and other lift parts should be kept free of corrosive agents, sol

vents, and road salts. If such agents are spilled or splashed on any lift component, immediately

rinse thoroughly with water and wipe down with a clean rag. Spray wire rope cables as required

with Penetrating Oil and wipe down.

Failure to keep lift free of corrosive agents and solvents will lead to reduced component service life, cable

failure, etc., which could result in property damage and/or personal injury.

2. Fasteners: Check all the attaching bolts and nuts for tightness.