Direct Lift PP8 Plus Long User Manual

Page 9

9

4.

If anchors do not tighten to 85 ft-lbs. installation torque, replace the concrete under each column base

with a 4’ x 4’ x 6” thick 3,000 PSI minimum concrete pad keyed under and flush with the top of existing

floor. Allow concrete to cure before installing lifts and anchors (typically 2 to 3 weeks).

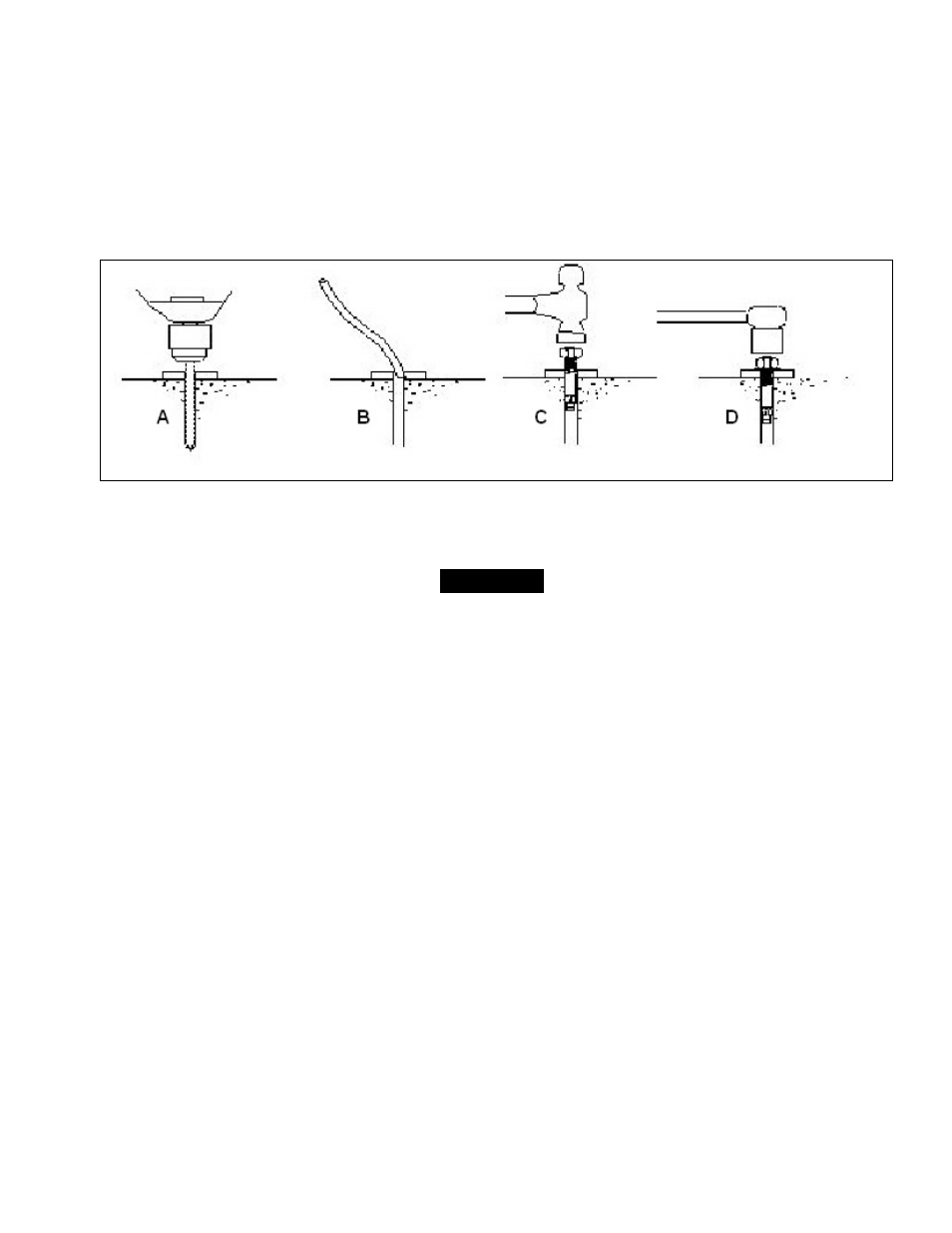

ANCHORING TIP INSTRUCTIONS

Anchors must be at least 6” from the edge of the slab or any seam.

1.

Use a concrete hammer drill with a carbide tip, solid drill bit the same diameter as the anchor, ¾”. (.775 to

.787 inches diameter). Do not use excessively worn bits or bits which have been incorrectly sharpened.

2.

Keep the drill in a perpendicular line while drilling.

3.

Let the drill do the work. Do not apply excessive pressure. Lift the drill up and down occasionally to re

move residue to reduce binding.

4.

Drill the hole to depth equal to the length of anchor. Note: Drilling thru concrete (recommended) will al

low the anchor to be driven thru the bottom of foundation if the threads are damaged or if the lift

will need to be relocated.

5.

For better holding power blow dust from the hole.

6.

Place a flat washer and hex nut over threaded end of anchor, leaving approximately ½ inch of thread

exposed carefully tap anchor. Do not damage threads. Tap anchor into the concrete until nut and

flat washer are against base plate. Do not use an impact wrench to tighten! Tighten the

nut, two or three turns on average concrete (28-day cure). If the concrete is very hard only one or

two turns may be required. Check each anchor bolt with torque wrench set to 85 foot pounds.

CAUTION!