Direct Lift PP8 Plus Long User Manual

Page 20

20

age (10 or more cycles per day, etc.).

Quarterly Inspection & Maintenance

1.

Cables

1.1 Inspect cables in both lowered and raised position. The cables may also be viewed through various

inspection holes and openings in yokes and runways. Check all the following:

a. That cables have no broken wires visible, reference Daily Inspection & Maintenance.

b. That cables are free of severe corrosion and pitting, reference Daily Inspection & Maintenance. A

light surface corrosion on exposed outer wires is normal. Penetrating Oil should be applied dur

ing monthly periodic inspection.

c. That there are no areas on the cable that have a greatly reduced diameter or “necking”, reference

Daily Inspection & Maintenance. When any cable is found with excessive necking, all cables must be

replaced immediately.

d. That cables do not have excessive stretch. It is normal for new cable to require adjustment during

“break-in”, after which small periodic adjustments may be required. However, if a cable that has

been in service for 6 months should suddenly require frequent adjustments or has used all

the cable adjustment available, all cables must be replaced immediately.

e. If any cable is found to be in need of replacement, the entire cable set must be replaced immediately.

f. Cables are expendable items and should be replaced as a set every 20,000 cycles (estimated) or every

6 years, unless earlier replacement is indicated during inspection.

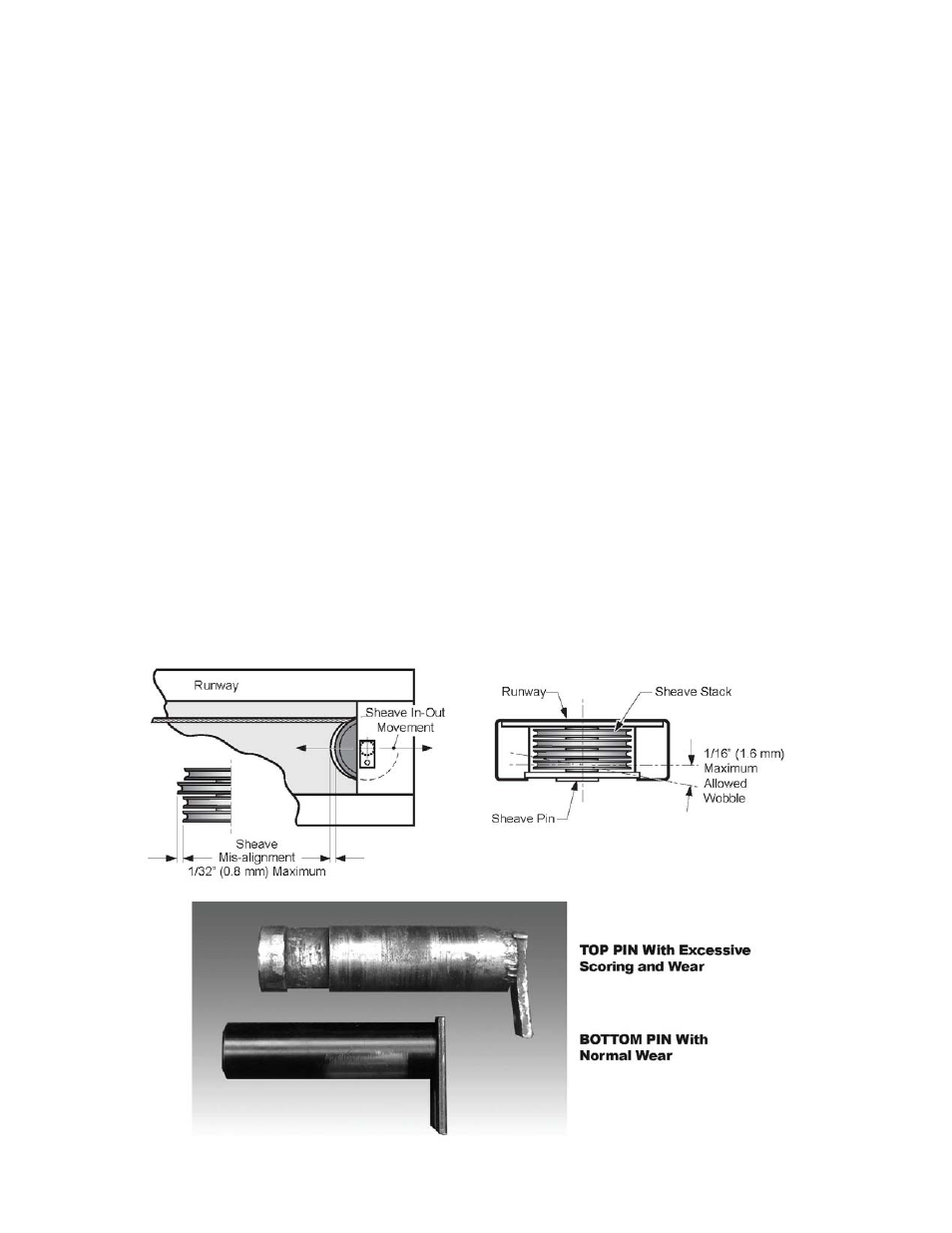

2. Sheaves and Pins

Inspect sheaves and pins in yokes and runways. Sheaves are expendable items. Sheaves and pins should be