Blagdon Pump X50 Metallic User Manual

Page 13

HG-CF-1099 Rev. Q – 05.09.13

Page 13

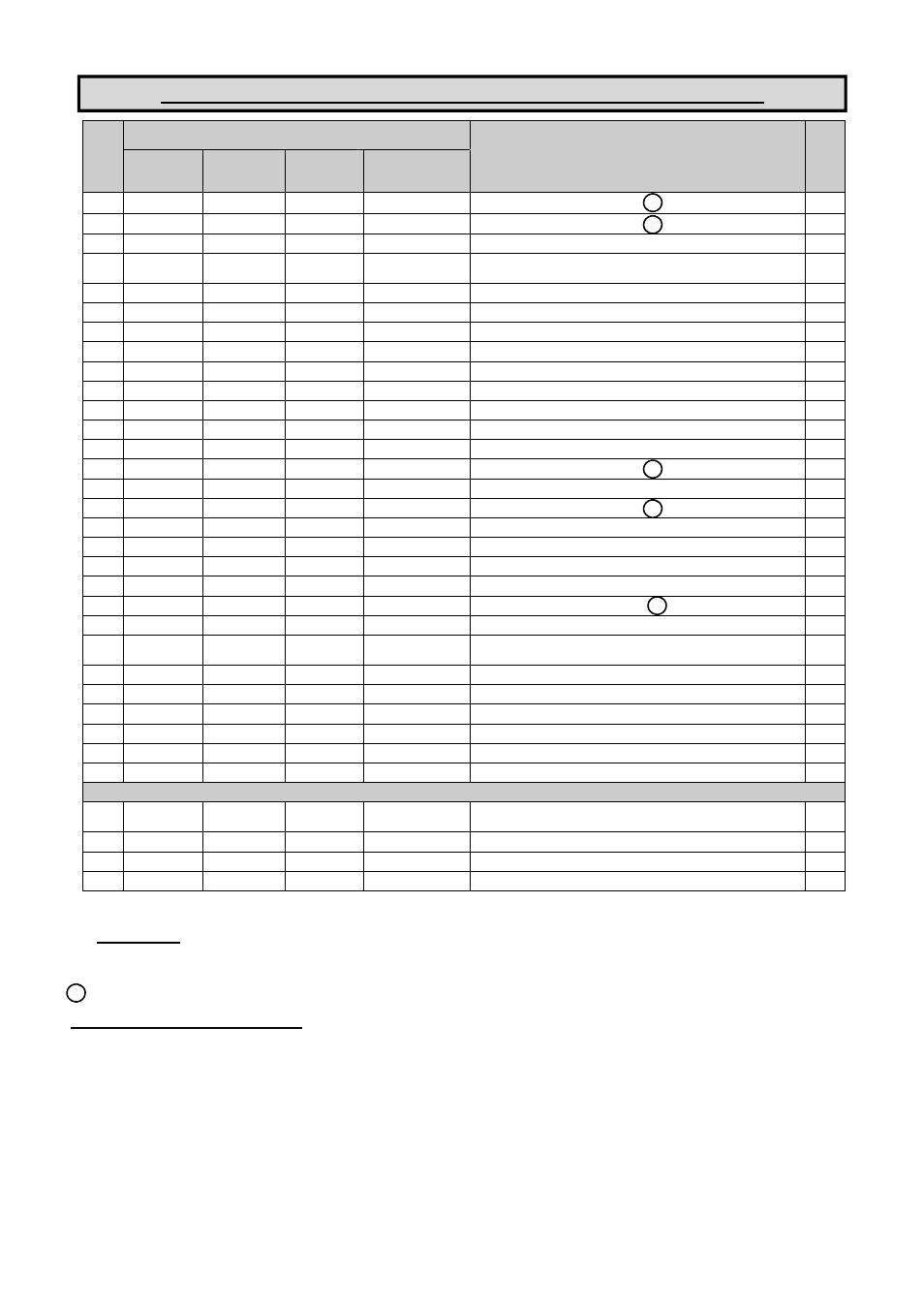

Wet Side Parts List - (Ref. Nos. are common to all models, pages 12)

PART NUMBER

DESCRIPTION

QTY

REF

No.

ALUMINUM

(COMMON)

CAST IRON

STAINLESS

STEEL

HIGH

TEMPERATURE

1

A041

-

A042

-

BOLT - HEX. HD.

M8 x 30

16

2

A005

-

A040

-

BOLT - HEX. HD.

M8 x 35

16

3

C013

-

C044

-

WASHER

M8

16

4

50-255

50-274

50-260

50-032

50-130

-

-

DISCHARGE MANIFOLD - BSP

DISCHARGE MANIFOLD - NPT

1

1

5

SEE TABLE

-

1B109

-

VALVE BALL

4

6

SEE TABLE

-

-

-

O-RING (METALLIC SEATS ONLY)

4

7

SEE TABLE

-

SEE TABLE

-

VALVE SEAT

4

8

SEE TABLE

-

-

-

O-RING (METALLIC & PTFE SEATS ONLY)

4

9

SEE TABLE

-

-

-

O-RING (METALLIC SEATS ONLY)

4

10

B507

-

B508

-

FLANGED NUT - SERRATED

M10

24

11

1B026

1B073

50-303

-

INNER COVER

2

12

D028

-

D310

-

SOCKET CAP SCREW

M8 x 25

12

13

SEE TABLE

-

-

-

DIAPHRAGM

2

14

A151

-

A145

-

BOLT - HEX. HD.

M10 x 45

24/16

15

B505

-

B506

-

FLANGED NUT - SERRATED

M8

16

16

A496

-

-

-

BOLT - HEX. HD.

M10 x 100

8

17

1B015

-

-

1B177

BUMP STOP

2

18

1B021

-

-

-

BACKPLATE

2

19

1B054

-

-

1B003

SUPPORT DIAPHRAGM

2

20

1B039

-

-

-

DIAPHRAGM - PTFE OVERLAY

2

21

SA10042

SA10044

SA10044

-

FRONTPLATE ASSEMBLY

2

22

50-253

50-258

50-052

-

OUTER COVER

2

23

50-254

50-265

50-259

50-033

50-129

-

-

SUCTION MANIFOLD - BSP

SUCTION MANIFOLD - NPT

1

1

24

SP475

-

-

-

NAMEPLATE

1

25

-

-

1B034

-

BASE LEG CAP

4

26

-

-

50-074

BASE LEG

2

27

C165

-

C173

-

WASHER - SPRING

M8

4

28

D490

-

D372

-

SOCKET CAP SCREW

M8 x 16

4

Atex models only :-

31

1A060

-

-

-

NAMEPLATE - SERIAL NO./MODEL NO.

(REPLACES ITEM 27)

1

32

SA10528

-

-

-

GROUNDING LEAD ASSEMBLY

1

33

SP467

-

-

-

ATEX NAMEPLATE

1

34

SP474

-

-

-

TIE-LOK TIE

1

A

C

C

B

B

- Wet Side Kits - These items are available in a recommended spares kit. Please refer to matrix on page 16 for details on part numbers

for ordering purposes or refer to your local stockist / distributor for further details.

Note! Wet Side Kits only include valve seats if the original parts were rubber :- i.e. Buna-N, Neoprene etc.

Indicates Torque setting required. See page 11 for details.

HIGH TEMPERATURE INSTALLATIONS

In situations where the temperature of the fluid to be pumped is likely to exceed 100°C, a high temperature pump code must be specified. This

is signified using an ‘X’ in the last part of the pump code as shown.

“XTS” in place of “TTS”. Reference Pump Code matrix on page 3

This indicates the following specification amendments :-

Diaphragm shaft seals will be changed from Polurethane to Viton. Back-up diaphragms and any bumpstops will be changed to Viton. In

extreme cases only, any gaskets could be changed to a higher temperature spec., and the diaphragm shaft bushes could be changed from

plastic to metal.

Refer to main table above and on page 14 for quantities / pump.

B