Blagdon Pump B10 Non-Metallic User Manual

Page 3

Page 6

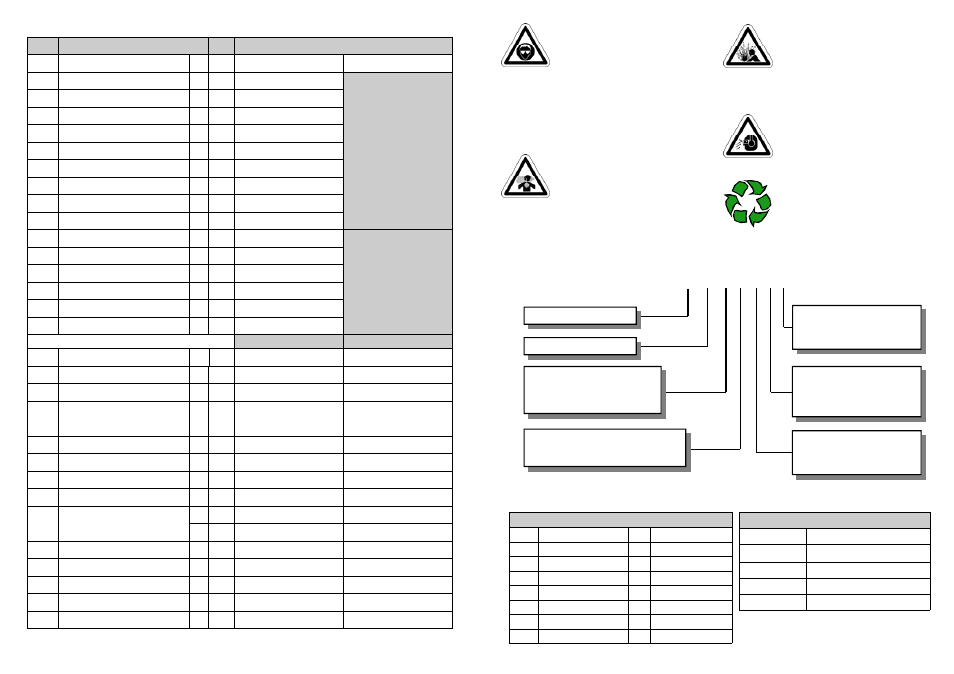

Parts List

Item

Description

Qty.

Standard: Polypropylene

1

Centre Section

1

E801A

2

Valve Gasket

1

E800J

AIR VALVE

ASSEMBLY

E800

(items 2 - 10)

3

Valve Insert

1

E500H

4

Air Diverter

1

10-075

5

End Cap

2

E800D

6

End Cap O-Ring

2

E500E

7

Valve Screw

4

10-050

8

Valve Body

1

10-048

9

Valve Spool

1

E500B

10

Valve Spool U-Cup

2

P98-104A

11

Main & Pilot Shaft O-Ring

8

E503B

PILOT VALVE

ASSEMBLY

12

Pilot Shaft Spacer

5

E503C

13

Shaft Retainer

2

E801B

14

Pilot Shaft

1

E803A

15

Pilot Shaft Snap Ring

2

E503D

16

Shaft Retainer Screw

4

E501C

POLY / SANTOPRENE PUMPS

KYNAR / PTFE PUMPS

17

Valve Seat

4

10-022(Poly) 10-039(Kynar)

18

Spring

4

10-030

10-030

19

Valve Stem

4

10-005

10-038

20

Valve Seat Seal

8

10-073

Santoprene Option

10-045

PTFE Option

21

Water Chamber Bolt (Short)

12

10-051

10-051

22

Water Chamber Bolt (Long)

4

10-052

10-052

23

Water Chamber

2

10-002

10-036

24

Foot Pad

4

10-035

10-035

25

Outer Diaphragm Plate

2

10-023(poly) 10-023(poly)

10-040(kynar)

10-040(kynar)

26

Diaphragm

2

10-032(R)

10-044

27

Inner Diaphragm Plate

2

C126

C126

28

Main Shaft

1

10-028

10-028

29

Manifold

2

10-003

10-037

30

Muffler

1

06-034

06-034

Page 3

Before pump operation, inspect all

gasketed fasteners for looseness caused

by gasket creep. Re-torque loose

fasteners to prevent leakage. Follow recommended

torques stated in this manual.

CAUTION!

Before doing any maintenance on the

pump, be certain all pressure is completely

vented from the pump, suction, discharge,

piping, and all other openings and connections. Be

certain the air supply is locked out or made

non-operational, so that it cannot be started while work

is being done on the pump. Be certain that approved eye

protection and protective clothing are worn all times in

the vicinity of the pump. Failure to follow these

recommendations may result in serious injury or death.

WARNING!

In the event of diaphragm rupture, pumped

material may enter the air end of the

pump, and be discharged into the atmos-

phere. If pumping a product which is hazardous or toxic,

the air exhaust must be piped to an appropriate area for

safe disposition.

WARNING!

Airborne particles and loud noise hazards.

Wear ear and eye protection.

WARNING!

RECYCLING

Many components of BLAGDON air

operated double diaphragm pumps are

made of recyclable materials. We

encourage pump users to recycle worn out parts and

pumps whenever possible, after any hazardous pumped

fluids are thoroughly flushed.

TYPICAL ORDER CODE =

B10. 01. P P. R P P

WETTED COMPONENTS

P : POLYPROPYLENE

K : PVDF (KYNAR)

NON - WETTED COMPONENTS

P : POLYPROPYLENE

VALVE SEATS

P : POLYPROPYLENE

K : PVDF (KYNAR)

VALVE STEMS

P : POLYPROPYLENE

K : PVDF (KYNAR

DIAPHRAGMS

R : SANTOPRENE

T : PTFE

DESIGN LEVEL

MODEL - B10

ITEM

DESCRIPTION

QTY PART NUMBER

2

VALVE GASKET

1

E800J

3

VALVE INSERT

1

E500H

4

AIR DIVERTER

1

10-075

6

END CAP O-RING

2

E500E

10

VALVE SPOOL U-CUP

2

P98-104A

11

PILOT SHAFT O-RING

6

E503B

11

MAIN SHAFT O-RING

2

E503B

ASK1001P - AIR SIDE KIT

WETTED END KITS

PART NO.

DESCRIPTION

SA10RPP

POLY./SANTOPRENE

SA10TPP

POLY./PTFE

SA10RKK

KYNAR/SANT.

SA10TKK

KYNAR/PTFE

SPARES KITS :- REFER TO TABLE & DRAWING ON PAGES 4,5 & 6

Note. These descriptions refer to the Pump body

and Diaphragm materials.