Blagdon Pump B10 Non-Metallic User Manual

Page 2

Page 2

SAFETY

Your B10 pump is a high performance unit

capable of achieving

high outputs at high

efficiencies. However, as is common with

pneumatic equipment, the pump efficiencies is

reliant upon the air being clean, dry and filtered.

Failure to comply with these requirements may

lead to loss of performance and reduced

component life and in extreme cases, permanent

damage to the pump.

To avoid leaks, ensure that all fluid connections

are tight. The use of PTFE thread tape correctly

applied should be used to ensure 100% leakproof

connections.

Failure to ensure 100% sealability of the

suction connection could adversely affect

suction performance.

If you are pumping hazardous fluids, or operating

the pump in an enclosed area, it is essential that

the exhaust from the pump is piped away to a

safe location. When pumping hazardous fluids

the above instructions must be adhered to in

order to ensure safe operating procedures.

(Under certain operating conditions the failure of

internal components can lead to the pumped fluid

being exhausted via the pump exhaust outlet).

WARNING

NEVER place your hands over or near the

pump suction inlet. Powerful suction could

cause serious bodily injury.

FLUSH THE PUMP

This pump was

tested with clean water. If this solution could

contaminate or react with the fluid you are

pumping, flush the pump thoroughly with a

solvent/detergent to clean internal components.

The solvent/detergent must be compatible with

the pump materials of construction. Care should

be taken to flush the pump each time it is

disassembled for maintenance or repair.

CAUTION

Ensure that only the

recommended grade of lubricating oil is used.

BLAGDON PUMPS do not require any dedicated

lubrication system, however a periodical

application of an SAE 10 lubricating oil will help to

prolong seal life. Other grades of oil may cause

the Air Logic System to operate intermittently,

thereby causing a loss of output and failure to

operate.

If the pump accelerates or is running too fast due

to a lack of fluid, then stop it immediately by

shutting off the air supply. A dry pump will

accelerate to a high speed causing wear to

elastomers.

If the fluid you are pumping tends to dry up or set

when it is not moving, then flush the pump as

often as necessary to prevent the fluid from

drying in the pump. Drain the pump thoroughly

before storing. If feasible, invert pump to allow

any fluid to drain from the non-return valves

.

When used for toxic or aggressive fluids,

the pump should always be flushed clean

prior to disassembly.

WARNING!

Take action to prevent static sparking. Fire

or explosion can result, especially when

handling flammable liquids. The pump,

piping, valves, containers or other miscellaneous

equipment must be grounded.

WARNING!

Before maintenance or repair, shut off the

compressed air line, bleed the pressure,

and disconnect the air line from the pump.

The discharge line may be pressurized and must be bled

of its pressure.

WARNING!

This pump is pressurized internally with air

pressure during operation. Always make

certain that all bolting is in good condition

and that all of the correct bolting is reinstalled during

assembly.

IMPORTANT!

Read these instructions completely, before

installation and start-up. It is the

responsibility of the purchaser to retain this

manual for reference. Failure to comply with the

recommendations stated in this manual will damage the

pump, and void factory warranty.

IMPORTANT!

Page 7

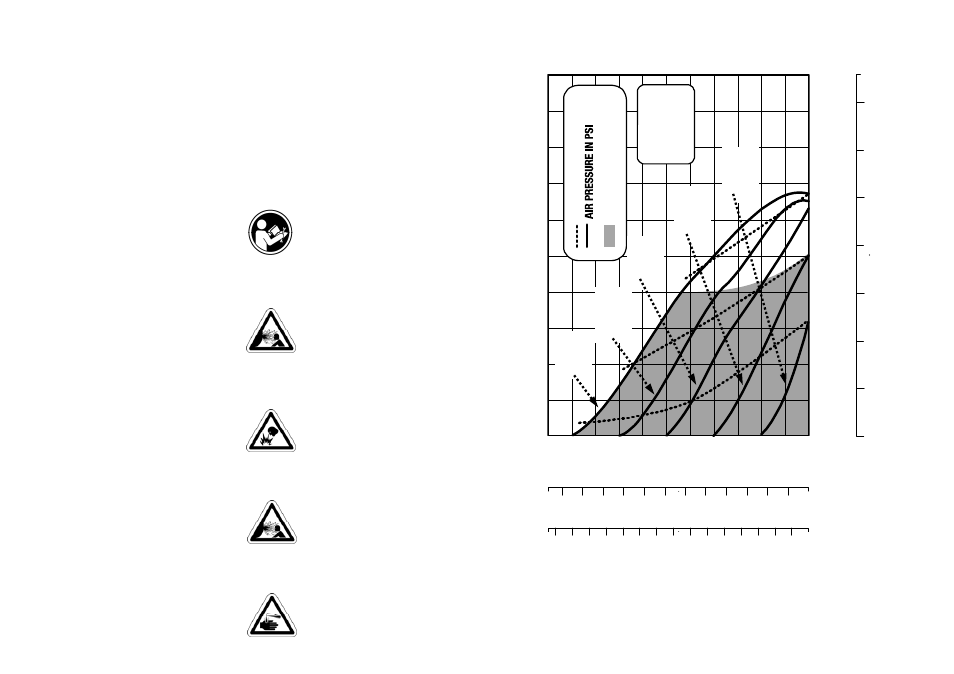

Performance Curve

All figures based on pumping clean water at ambient temperature

Meters

Fe

et

Discharge Head in PSI

15

3

0

100

90

80

70

60

50

40

30

20

10

0

240

220

200

180

160

140

120

100

80

60

40

20

0

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

6

4

27

8

9

0

5

1

0

1

52

02

53

0

3

5

Capacity in Liters

P

er Minut

e

Capacity in U.S

. Gallons

P

er Minut

e

D

is

p

la

ce

m

en

t

P

er

S

tro

ke

, 0.

009 G

a

l

. (0

.0

3

4

L

)

1

3

5

SCFM

M

3

/HR

1

1.7

3

5.1

5

8.5

R

ec

om

m

ended O

per

at

ing

A

rea

Displacement Per Stroke, 0.

00

7 Gal. (UK) (0

.034 L)

AIR CONS

UMPTION

IN CFM

CFM

Capacity in U.K. G

allons per Minute

Capacity in Liter

s per Minute

Feet

0.8

1.7

2.5

3.3

4.2

5

5.8

6.7

7.5

20 psi

(1.4 bar)

40 psi

(2.8 bar)

60 psi

(4.1 bar)

80 psi

(5.5 bar)

100 psi

(7 bar)

These items are available as a recommended Air Side Kit, ASK1001P, see page three for details.

These items are available as a recommended Wet Side Kit, see page three for Part Nos.

For any further information regarding available kits, please contact your local stockist / distributor.