General Technologies TA300 SmarTach D : Digital Diesel Engine Tachometer User Manual

Page 5

Page 8

Page 7

4- While holding the (Trigger Level Adjust) button pressed, use the

(Sensitivity

Adjust increase) or (Sensitivity Adjust decrease) buttons to adjust the % value.

Notes:

• Adjusting the trigger level of the TA300 while performing RPM measurements, provides

quick feedback on how this setting affects the response of the TA300 in any given

situation.

• The trigger level can be adjusted between 20% and 80%. The default value for the

trigger level is 50%.

• For example, if the trigger level is set to 70%, the TA300 will register an engine cycle

when the signal level from the piezoelectric sensor reaches or exceeds 70% of the

maximum signal.

• Higher trigger levels increases the noise rejection, and lower trigger level will help in

measuring RPM when dealing with inconsistent injection pulses. For most cases the

default 50% level is the optimal value.

• The values set by using the Trigger Level Adjust function are stored in internal memory,

and will be retained even if the instrument is powered off, the battery is depleted or

is removed.

4. APPLIcATION INFORMATION

4.1 Using the piezoelectric sensor

Important

The piezoelectric sensor is constructed with an special piezoelectric

ceramic material and it can be easily damaged by impacts or if excessive

pressure is applied.

1- For the piezoelectric sensor to work, it requires that a good electrical connection be

established between the center part of the sensor, and the ground clip. This can be

achieved in two ways:

• Fit the piezoelectric sensor to a clean unpainted section of an injection line. Then

connect the ground clip to that same clean section of the injection line as shown in

Fig. 3. or to a convenient ground in the engine. If necessary scrape and sandpaper

the line in order to expose the metal surface.

• If you do not wish to scrape the fuel line, you could tightly wrap a piece of aluminum

foil around the pipe and clamp the piezoelectric sensor over this foil. Make the foil

wrap long enough to allow placing of the ground clip on the same piece of foil. Use

of aluminum foil will often fix problems due to bad electrical connections between

the piezoelectric sensor and the injection pipe and ground clip.

2- Do not over tighten the clamp. Use of excessive force or tools such as pliers to tighten

the clamp will result in damage to the piezoelectric sensor and void the guarantee.

3- If not already connected, locate the forked terminal at the end of the red wire (near

to the alligator ground clip) and push it under the flat head of the connector pin at the

corner of the piezoelectric sensor. This connector pin is the one with a coil spring. You

will see that this spring presses a conical washer against the flat pin head. The forked

terminal must be inserted between this washer and the flat pin head. Hook up is now

complete.

4.2 Troubleshooting

The main factors that may cause unstable, erroneous or in some cases prevent the TA300

from obtaining a reading at all are:

• Poor electrical contact between the center of the piezoelectric sensor and the

ground clip.

• Engine/fuel line vibration.

• Weak signal due to the characteristics of the fuel line or the fuel injection

pump.

4.2.1 Poor electrical contact

Please refer to ‘4.1 Using the piezoelectric sensor’ for detailed instructions on how to use

the sensor.

4.2.2 Engine/fuel line vibration

The piezoelectric sensor is specially designed to detect the expansion of the fuel line cause

by the pulses of pressure generated by the fuel when injected into the cylinder. However

under some conditions the vibration of the engine and fuel line may cause an excessive

amount of noise in the signal, in which cases the TA300 may not recognize the signal and

generate incorrect RPM readings or no reading at all.

Possible solutions:

• Use the Trigger Level Adjust function to change the trigger level until a stable RPM is

obtained.

• Sometimes the vibration noise may be caused or magnified by the minute ‘jerking’ of

the cable connecting to the piezoelectric sensor to the TA300, and providing some

strain relief may be of help in obtaining RPM readings. To provide strain relief to the

piezoelectric sensor, attach the red wire (which is connected to the sensor ) to the

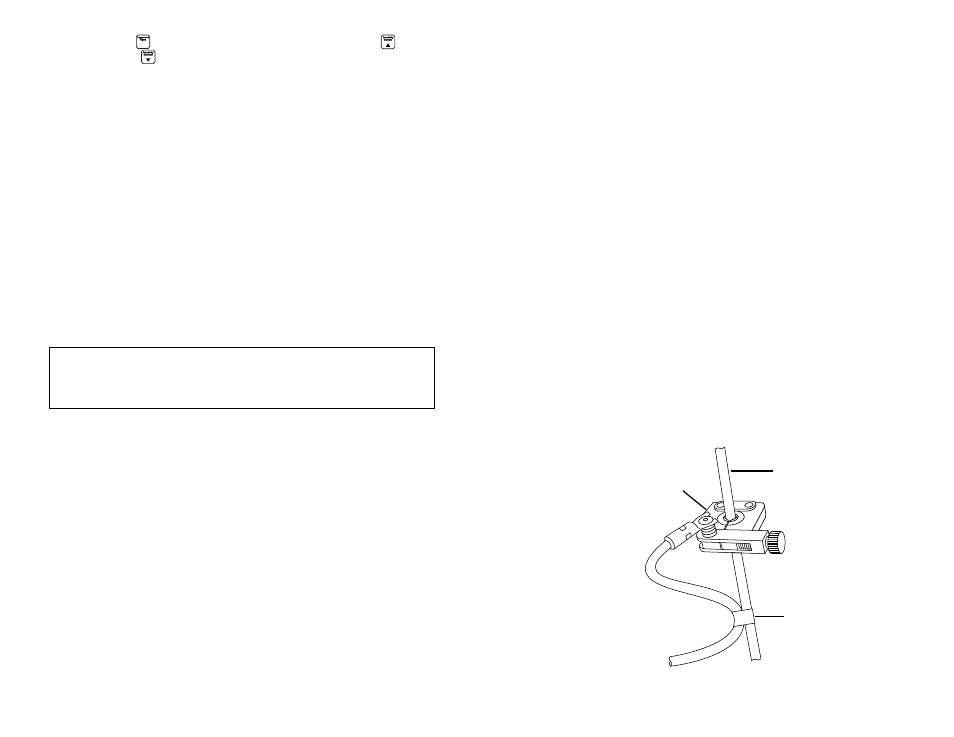

same fuel line using electrical tape or a cable tie, as shown in Fig 4.

Fig. 4 - Strain relief setup for piezoelectric sensor

Fuel injection line

Piezoelectric sensor

Electrical tape or cable tie