Max. internal earth connection: 0.5 - 2.5-mm – Fire Fighting Enterprises Vibration Switch: Explosion Proof User Manual

Page 2

Doc. No. 0115-03

Page 2 of 4

30.01.06

All suitable for Zone 1 & Zone 2 use.

Ingress Protection Rating IP67 although any IP rating down to IP54 may be used if required, see Item. 8.6

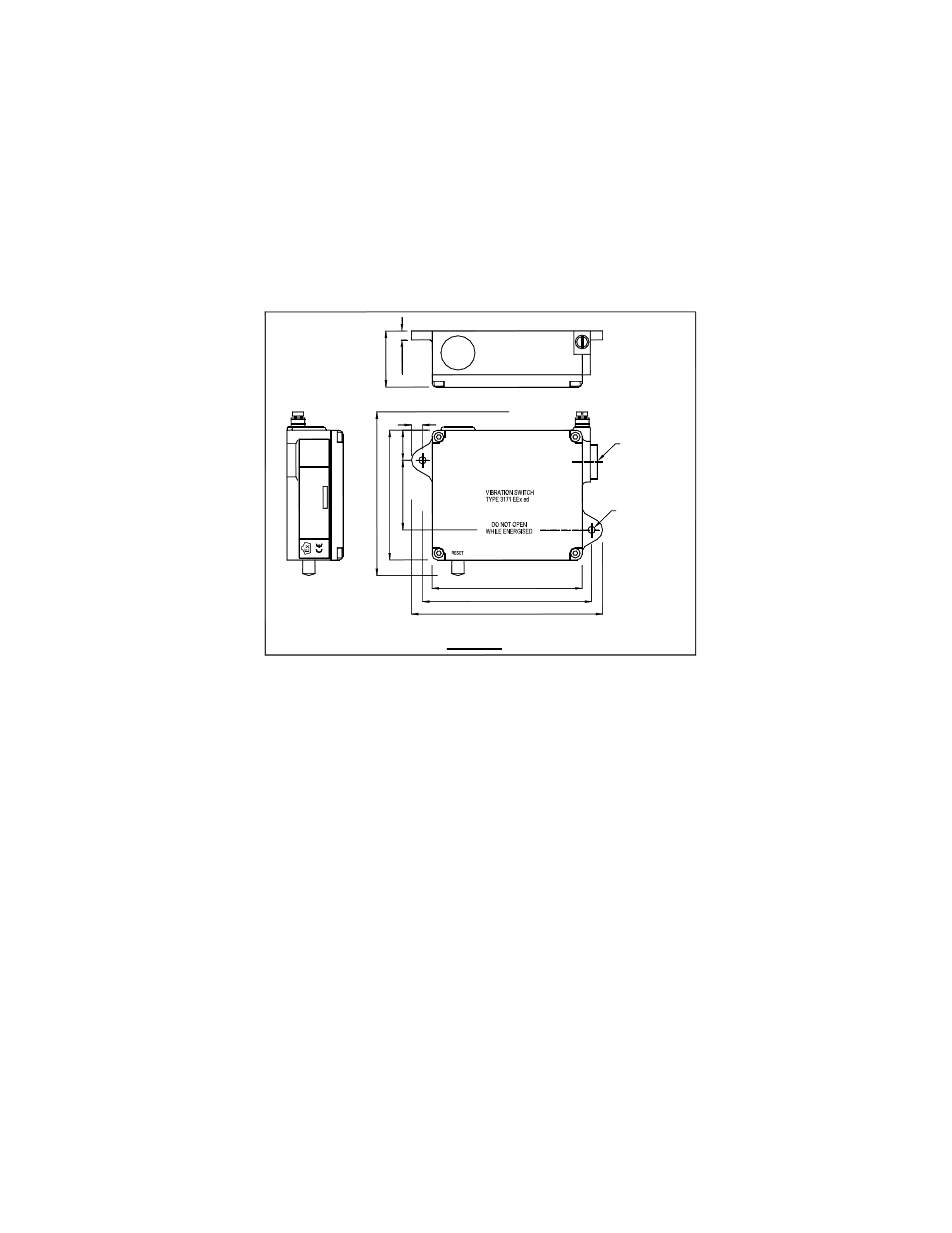

2. MOUNTING AND DIMENSIONS

The unit should be firmly mounted on a vertical face by M4 bolts, with the reset button at the bottom. See Fig. 1

for external dimensions and fixing centres.

The vibration switch will respond to vibrations in any axis (predominantly in a horizontal plane) and should be

fitted on the machine such as to ensure good transmission from likely sources of excess vibrations.

CABLE ENTRY

LEVEL

FIGURE 1

ENGLAND

2 POSNS.

FIXING HOLES

5.0 DIA.

M20 x 1.5 ISO

SET

41

m

m

6.

5m

m

8mm

22m

m

51

m

m

C

e

n

tre

s

95

m

m

1

20m

m

Ov

e

rall

110mm

124mm Centres

140mm Overall

PRINCIPLES OF OPERATION

The vibration switch is a simple mechanical device, operating by balancing magnetic attraction on a metal ball,

against acceleration forces produced by surrounding vibrations. The switch is mounted vertically with the ball

restrained in a conical seat by a permanent magnet. When the ball experiences sufficient acceleration,

(excessive vibration of the machine), it breaks free, falls and operates a Microswitch. The Microswitch provides

the electrical interface to cause machine shut – down.

Reset is by Push Button on the bottom of the switch. See Fig. 1

The operate point is controlled by the Set Level Screw on top of the switch. See Fig. 1

3. ELECTRICAL

CONNECTIONS

Contact Ratings: see Tables 1 & 2

Connections: see Fig 2

Connector core size: 0.5 - 2.5-mm

2

max.

Internal earth connection: 0.5 - 2.5-mm

2

max. (To match connector cable used)

External earth connection: 6.0 mm

2

max.

Approved cable glands must be used to suit cable and ensure acceptable IP requirements - See Item 8.6.

To ensure EMC requirements are met, it is recommended that SWA, MICC, Screened cable, or metal conduit

be used, with suitable earthing.