Installation and operation, Installation location, Rigging – Fulton Ancillary Equipment Horizontal and Vertical Return Systems User Manual

Page 11: Piping

RTN IOM

9

Installation Location

The condensate return system should be

located to permit access to operating controls,

instruments and inspection openings.

The foundation should be level and

designed to support the load. Calculations

should be based upon the maximum or

filled weight of the system.

Rigging

Qualified riggers should be used to place

the system on the foundation. All rigging

equipment must be carefully placed to

avoid damaging or loosening piping,

nozzles and other parts of the assembly.

The system should be securely bolted to

the foundation.

Piping

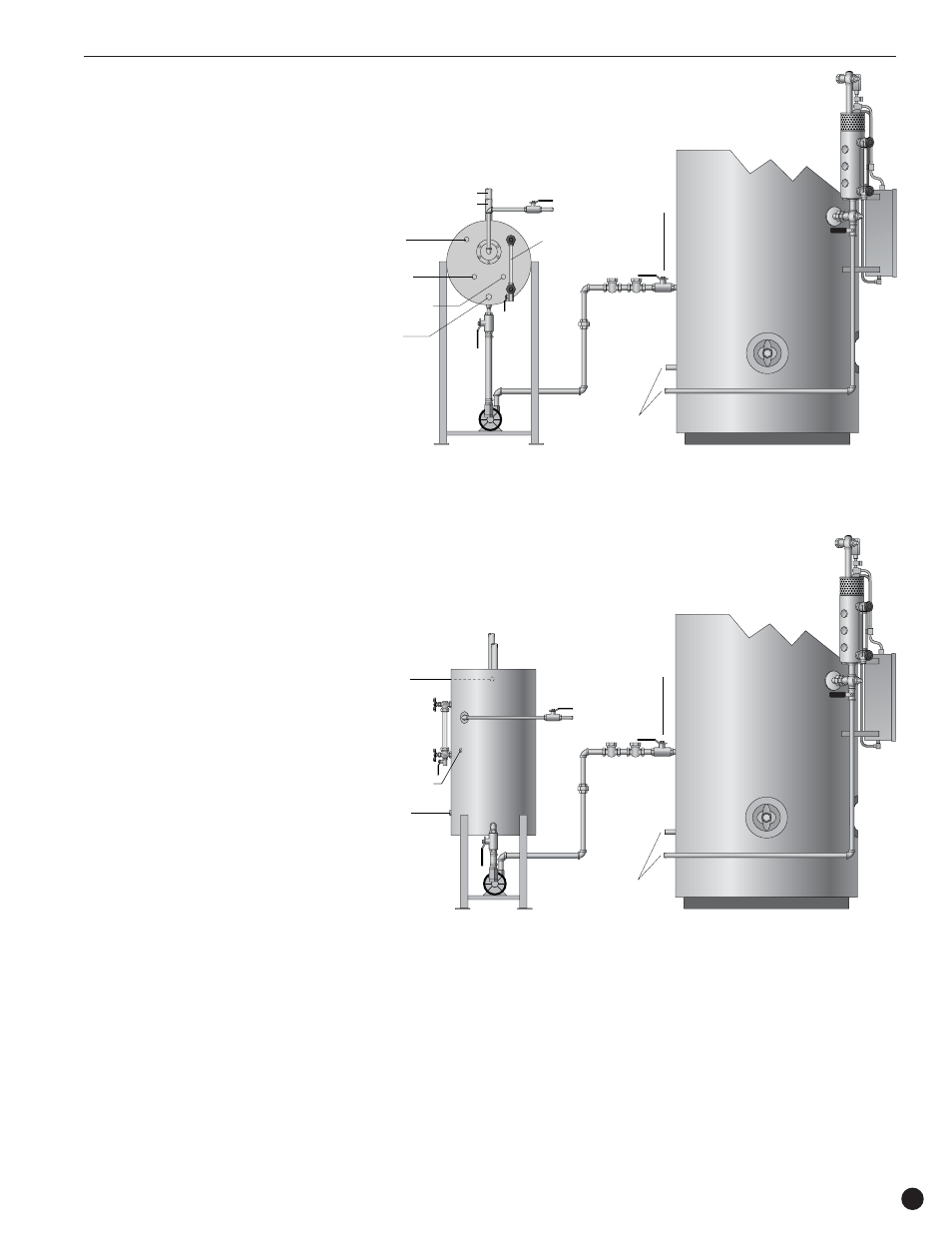

(Figures 1 and 2)

1. Prior to piping, all foreign material or

debris must be removed to prevent

possible malfunctions. Clean tank by

flushing with hose.

2. Avoid imposing any piping strain on the

pump(s). Provide expansion joints and

independently supported pipe hangers

where necessary.

3. Isolating valves are installed to allow for

cleaning or repairs.

4. Make-up water and pump discharge

piping must be sized in accordance with

any applicable local or state codes.

Sizing should be determined by flows,

pressures, and distances, not pump size.

5. Install a stop valve and two check valves

in the pump discharge line.

6. Vent piping should be vertical, full size,

free of valves, bends or restrictions and

piped to a safe location.

7. Over flow piping should be full size, free of

obstructions and piped to a safe location.

Installation and Operation

Condensate

Return Tank

Cold

Water

Supply

Thermometer

*

Steam

Injector

*

Electric

Control

Panel

Water Column

and Sight Glass

Shut Off

Valve

To Blowdown

Separator

Overflow

Opening

Sight

Glass

Union

Check

Valves

Vent

Pump/

Strainer

Return

*

Supplied with optional preheat kit assembly

(NOTE: Aquastat opening is the same dimension off centerline of sightglass but on opposite side)

Oil, Gas or

Electric Boiler

Aquastat

*

Figure 1

Condensate

Return Tank

Cold

Water

Supply

Thermometer

*

Aquastat

*

Steam

Injector

*

Electric

Control

Panel

Water Column

and Sight Glass

Shut Off

Valve

To Blowdown

Separator

Overflow

Opening

Sight

Glass

Union

Check

Valves

Vent

Pump/

Strainer

Return

*

Supplied with optional preheat kit assembly

(NOTE: Aquastat opening is the same dimension off centerline of sightglass but on opposite side)

Oil, Gas or

Electric Boiler

Figure 2