Installation details-automatic powerstop, Concrete dock face, Low pit floor – Poweramp POWERSTOP 4.2009 User Manual

Page 9: Driveway mount, Cantilevered dock

7

4111-0014 — November 2006

Sept.2007

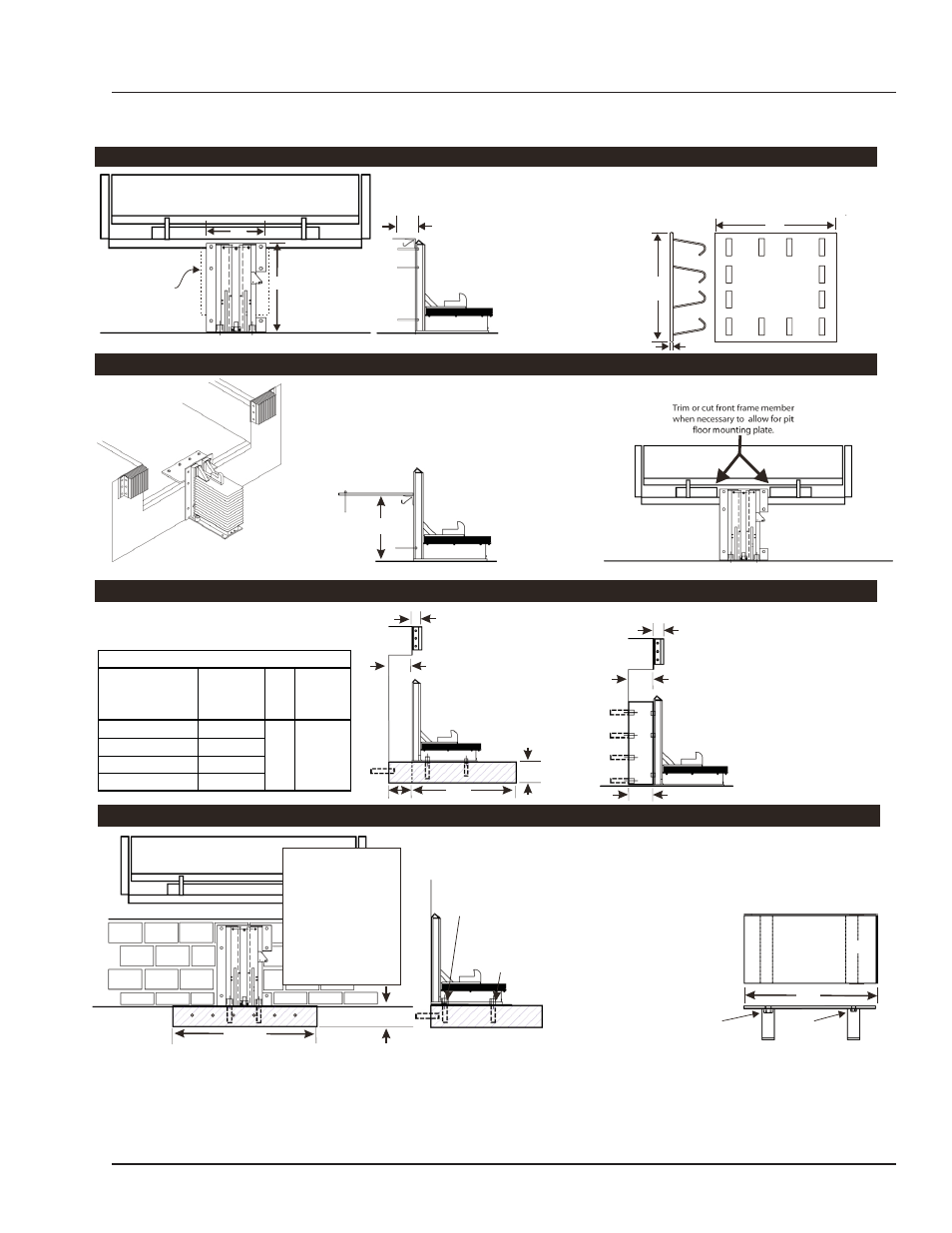

INSTALLATION DETAILS-AUTOMATIC POWERSTOP

A

ti

i

d

t i

t

i i

ff

t t S

t

I

W

th

i ht t

k

d

t h

ith

t

i

ti

Concrete Dock Face

(Standard installation)

Low Pit Floor

(Distance from pit floor to drive under 24”)

Driveway Mount

(Recommended when dock face is unsuitable for PowerStop Mounting)

Cantilevered Dock

(For bumper projection >4” or cantilevered dock or Edge-of-Dock leveler)

48”

8” Min.

Driveway mount requires

attachment to a concrete

drive greater than 8”

thick. For asphalt drive,

pour 48”x48”x8” (min.)

concrete pad and include

six (6) 3/4” dowels into

foundation wall. Then

proceed with adhesive

anchors or weld plate

embed.

Anchor pit floor mounting plate (minimum 3/8” x 20”W x 8” D)

(Part #9414-0056) with four (4) (3/4”x 5 1/4” min.) wedge anchors.

Weld mounting plate to curb steel and back plate of PowerStop with

a continuous 1/4” fillet weld. Anchor back plate of PowerStop to

dock face with a minimum or (4) 3/4” x 5 1/4” wedge anchors

(Kit#2103-0003).

Determine offset

then proceed with

“Driveway Mount”

instructions below.

20”

20”

Weld three sides of PowerStop back plate to the optional

embed mounting plate (Part #7953-0119) with ten (10)

4” long 1/4” fillet welds.

5 1/4” minimum

27”

To determine size offset required, take total effective

bumper projection (bumper size plus any cantilever) and

subtract 4”.

48”

8” Min.

Using back plate as a guide, drill six (6) holes for

wedge anchors (3/4”x 5 1/4” min.) (Kit #2103-0003)

(Kit #9414-0058)

Install two (2) 1” Dia. adhesive

anchors into 1-1/8” Dia. x 7”

deep hole at rear of PowerStop.

Install two (2) 3/4”

Dia. x 5 1/4” min.

wedge anchor at

front of PowerStop.

Adhesive Anchors Method

Drive Embed Method

Wedge Anchors Method

Wall Embed Method

27”

14”

Weld method

Properly locate and level the drive embed weld plate (Part#7953-

0059) in the drive approach. Observe Cantilever conditions for

proper positioning. Weld restraint to embed plate with a

continuous ¼” filet weld.

Bolt on Method

Properly locate and level the

drive embed plate

(Part#9414-0057) in the drive

approach. Observe cantilever

conditions for proper positioning.

Using the bolts included, bolt

the restraint to the embed plate.

If <24”

18”

Optional

Embed

Plate

3/8”

(Front)

3/4” Dia. X 6” min.

bolt

(Rear)

1” Dia. X 6” min.

bolt

Driveway Mount

Wall Mount

Dim. B

Dim. A

Offset Formula

Dim. A

Dim. B

Offset

Bumper Projection

Cantelever

4"

+ Dim B

6"

+ Dim B

-4" = Offset

10"

+ Dim B

15"

+ Dim B

For filler requirements from 1 ½”to 7

½” use cantilever bracket #9414-0052

weld to embedded

mounting plate (Part #7953-0119)

For filler requirements for 8 3/4” to 13

3/4” use cantilever bracket #9414-

0053 and anchor cantilever bracket to

the dock face (3/4” Dia. X 5 1/4” min.)

(Kit #2103-0004) or weld to

embedded mounting plate

(Part #9414-0052).

and anchor cantilever bracket to the

dock face or

Dim. B

Dim. A

Offset

Dim. B