Nova-Tech Pulsafeeder Visual Flow Meter User Manual

Flowmeter instruction sheet

FLOWMETER INSTRUCTION SHEET

U0817447

Rev A

INSTALLATION:

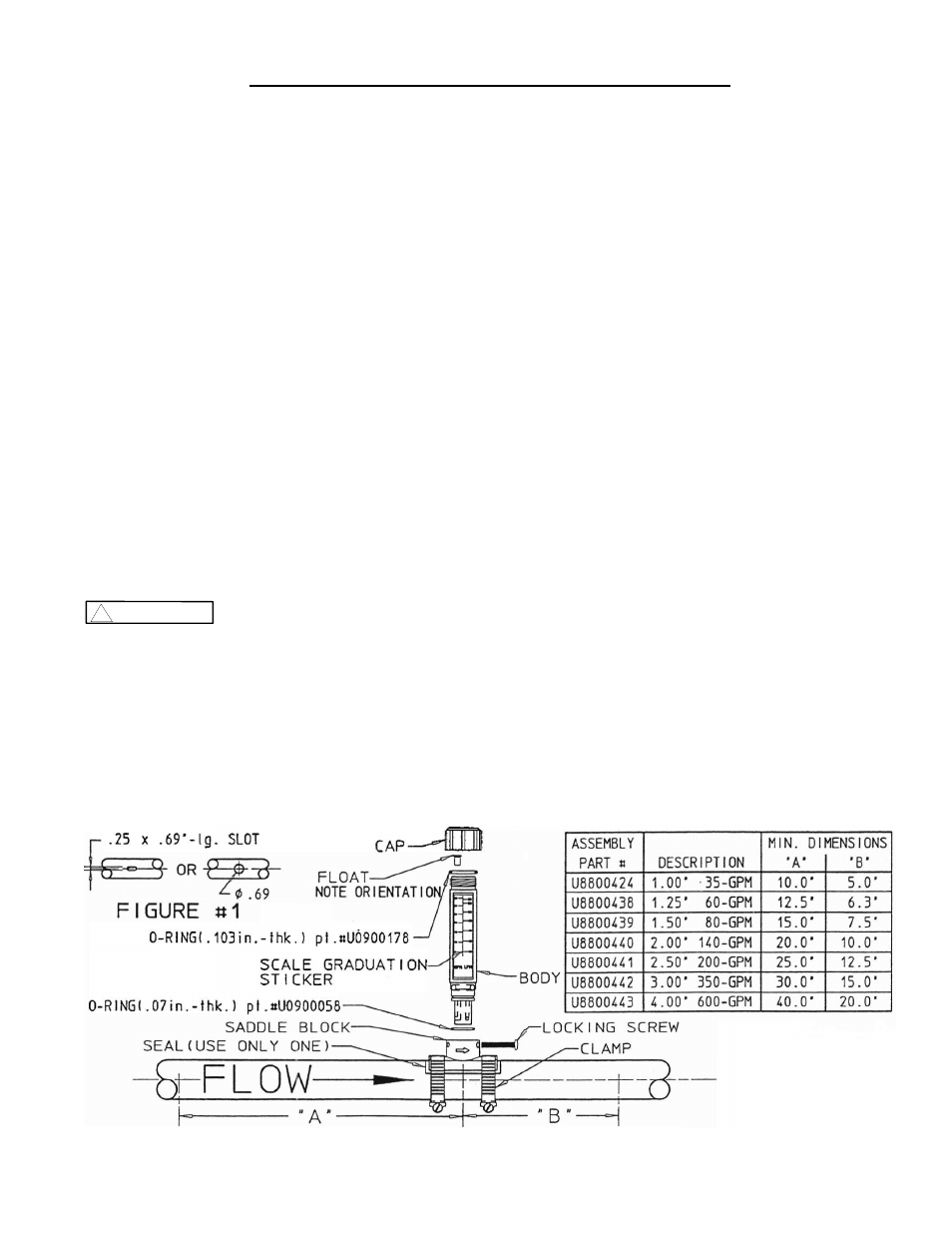

Depressurize and drain the system before attempting to install the flowmeter. The flowmeter must be

located in a straight, horizontal section of pipe that will provide the minimum “A” and “B” dimensions

(Refer to figure below). There can be NO BENDS or RESTRICTIONS within these dimensions.

Drill a .69in.-Diameter hole through top center of pipe or make a slot .25in. wide x .69in. long (See Figure

#1). Remove all sharp edges and burrs. Check fit of flowmeter body into the hole. It must fit freely and

BE INSTALLED VERTICALLY.

Select one of the seals and place between the saddle block and the pipe. NOTE: Two seals are included.

Use the thin seal (PT# U0811791) on plastic pipe and the thick seal (PT# U0816177) on copper pipes.

BE SURE FLOW ARROW ON SADDLE BLOCK POINTS IN THE DIRECTION OF FLOW.

Open the two mounting clamps. Place around pipe and saddle block, as shown, and tighten.

Tighten clamps only enough to stop leaks. DO NOT OVER TIGHTEN.

Re-pressurize the system and check for leaks.

PRESSURE and TEMPERATURE LIMITS:

Maximum temperature limit = 120 degrees F; Maximum pressure limit = 120-PSI. Pressure and

temperature limits are inversely proportional. If the pressure is at 120-PSI, and the temperature is at 80

degrees F, de-rate pressure 1-PSI for every 1 degree F increase

.

Because many factors can affect the performance of the flowmeter, such as excessive vibration,

misalignment, certain chemicals and neglect, to name a few, it is important that the user properly

maintain the flowmeter to assure the highest performance.

MAINTENANCE:

No adjustments and little maintenance are required. Occasionally, the flowmeter should be cleaned to

maintain accuracy. Cleaning procedure is as follows:

! CAUTION

: DEPRESSURIZE THE SYSTEM BEFORE DISASSEMBLING THE FLOWMETER.

FOLLOW ALL SAFETY PRECAUTIONS WHEN HANDLING THE CLEANING SOLUTION. RUBBER

GLOVES, EYE PROTECTION AND PROTECTIVE CLOTHING ARE AN ABSOLUTE MINIMUM

REQUIREMENT.

Turn out and remove the locking screw. Lift straight up to remove body assembly from the saddle block.

Remove the cap from flowmeter body and flush all parts with water. If brown staining is evident, clean

inside of body with a solution of 5%-hydrochloric acid. DO NOT GET ACID ON METAL PARTS or ON

SCALE GRADUATION STICKER. Reassemble flowmeter, being sure the float is installed as shown

below. Place flowmeter body assembly into the saddle block and secure with locking screw.