Maintenance, Tubing assembly removal – Nova-Tech Chem-Tech XP Series User Manual

Page 10

REV. L PN J63031

- 10-

3. Depress and hold the Momentary-On (100%) button until the chemical is

present in the discharge line up to the injection point.

4. If the pump is an adjustable model rotate the percentage knob to the desired

feed-rate setting. Turn the rocker switch to the continuous-On position.

6. Maintenance

NOTE: It is recommended that volume output be measured at initial start-up, at

every tube change, and after every 250-hours of operation. Use the flow rate

stated on your data label as a guide. More critical applications may require more

frequent verification.

NOTE: NO USER SERVICEABLE COMPONENTS ARE INSIDE THE

ENCLOSURE. IF THE POWER SUPPLY CORD BECOMES DAMAGED, IT

MUST BE REPLACED BY PULSAFEEDER, ITS REPRESENTATIVE, OR A

SIMILARLY QUALIFIED TECHNICIAN IN ORDER TO AVOID A HAZARD.

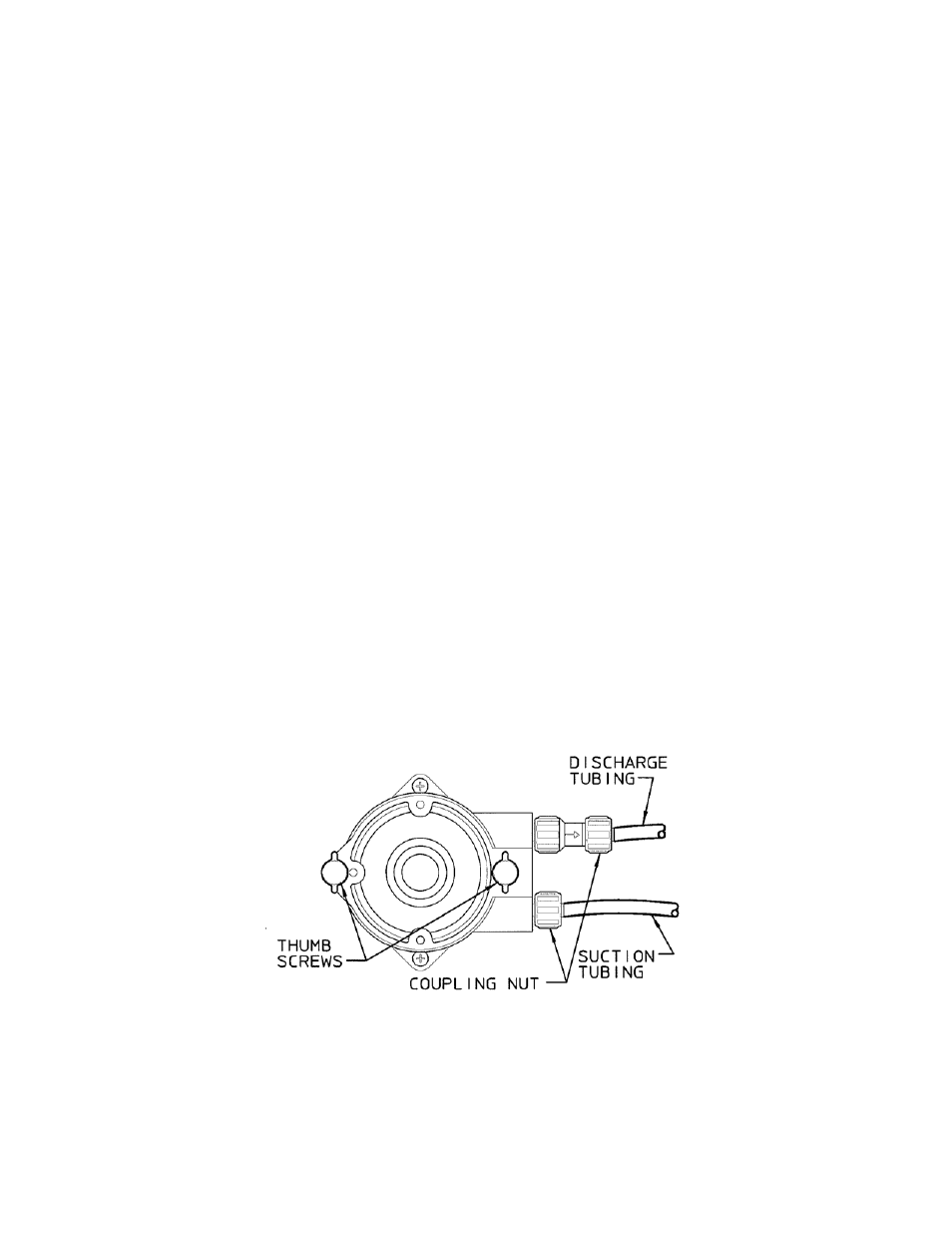

6.1. Tubing Assembly Removal

Always wear protective clothing and safety glasses when working on the

chemical pump and refer to the chemical manufacturers’ safety precautions.

1. Remove the power to the pump and place the rocker switch in the Off (“O”)

position.

2. Relieve the system pressure and the drain discharge and suction tubing.

3. Loosen coupling nuts and remove the tubing from suction and discharge

ports. See figure 7a.

Figure 7a: Pump Head Assembly with Front Cover Attached