Warning – Detroit Radiant Products Company UH Series User Manual

Page 19

19

UH

Series

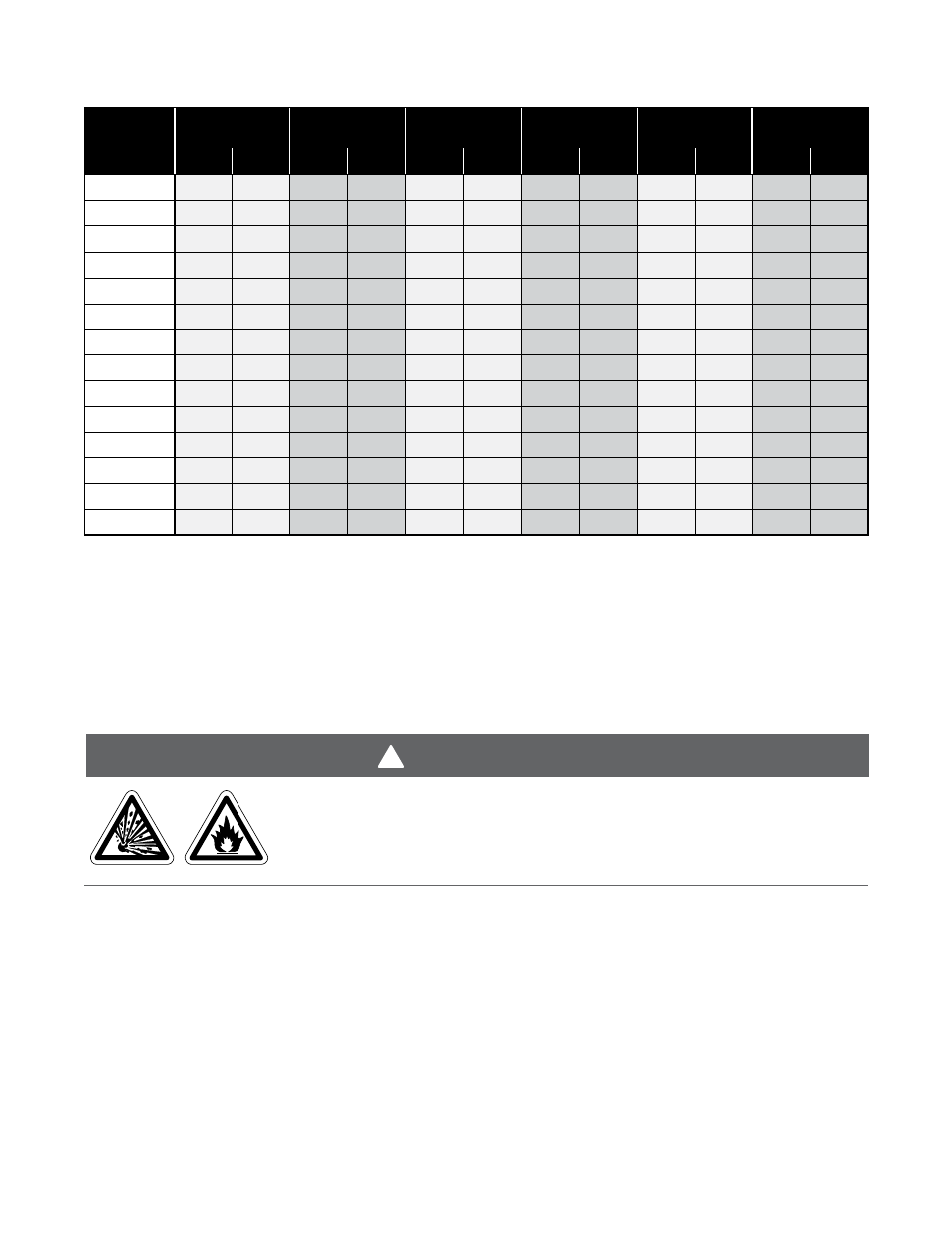

Chart 3.4

•

Maximum capacity for Schedule 40 Metallic pipe, in CFH

The UH Series heater is equipped to receive a gas supply line nipple of ½”NPT Schedule 40 metallic

pipe. All piping must be installed in accordance with the requirements outlined in the National Fuel Gas

Code ANSI/Z223.1 (latest edition) or CSA-B149.1 and B149.2. Support all gas supply piping with pipe

hangers, metal strapping, or other suitable material. Do not rely on the heater to support the gas pipe.

When connecting piping to the unit, the use of a thread joint compound is required. The thread

compound (pipe dope) shall be resistant to the action of liquefied petroleum gas or any other chemical

constituents of the gas to be conducted through the piping. Use of Teflon

®

tape is not permitted.

Install a ground joint union with a brass seat and a manual shut off valve adjacent the unit for

emergency shut off and easy servicing of controls. A 1/8” NPT plugged tap that is accessible for a test

gauge connections is also recommended, as illustrated in Figure 3.4.

A sediment trap must be installed in the supply line in the lowest spot prior to connecting to the heater.

The trap length shall be at least three inches long. Ideally, the trap would be installed as close as

possible to the shut off, as shown in Figure 3.4.

3.0

Installation

•

Gas Supply Installation Instructions

Pipe

Length

(feet)

1/2”

3/4”

1”

1-1/4”

1-1/2”

2”

Nat

L.P.

Nat

L.P.

Nat

L.P.

Nat

L.P.

Nat

L.P.

Nat

L.P.

10’

132

86

278

182

520

340

1050

686

1600

1046

3050

1993

20’

92

60

190

124

350

229

730

477

1100

719

2100

1373

30’

73

48

152

99

285

186

590

386

890

582

1650

1078

40’

63

41

130

85

245

160

500

327

760

497

1450

948

50’

56

37

115

75

215

141

440

288

670

438

1270

830

60’

50

33

105

69

195

127

400

261

610

399

1150

752

70’

46

30

96

63

180

118

370

242

560

366

1050

686

80’

43

28

90

59

170

111

350

229

530

346

990

647

90’

40

26

84

55

160

105

320

209

490

320

930

608

100’

38

25

79

52

150

98

305

199

460

301

870

569

125’

34

22

72

47

130

85

275

180

410

268

780

510

150’

31

20

64

42

120

78

250

163

380

248

710

464

175’

28

18

59

39

110

72

225

147

350

229

650

425

200’

26

17

55

36

100

65

210

137

320

209

610

399

WARNING

!

Always use two (2) opposing wrenches to tighten mating pipe connections

to prevent excessive torque on the gas valve and manifold pipe. Excessive

torque can damage the valve and/or misalign the orifice, resulting in fire,

explosion, serious injury or death.