Best-practice wall shingles – DCI Products RafterVent User Manual

Page 3

3

wrapped walls, and the matrix compresses

a little when the shingles are installed on

top, leaving an effective

1

/

4

-inch air

space. The corrugations should be ori-

ented vertically for the best drainage and

airflow, and the edges of the mat should

not be overlapped.

On the plus side, Home Slicker is only

1

/

4

inch thick — not nearly the

3

/

4

inch my

furring strips padded out the shingles. The

butt lines of each shingle course laid over

Home Slicker flush out with

5

/

4

-inch cor-

ner boards applied directly over the house-

wrap. And the butt lines come close to, but

not past, most flanged window jambs. The

sheets go up quickly with no special lay-

out, but it is important to cut Home

Slicker close to trim such as window cas-

ing and corner boards. If you leave a wide

space (

3

/

4

inch or more), the unsupported

shingle edge is likely to split.

On the downside, fastening shingles

over Home Slicker takes a deft hand.

The bottom few shingle courses are the

hardest to install. The matrix is spongy, so

hand-driving nails is a challenge, and

pneumatically driven staples or nails eas-

ily overdrive even with the air pressure set

low. You’ll end up splitting more shingles

in the first two rows than on the rest of

the wall. Subsequent courses are sup-

ported by the shingles beneath, so the

going gets a little easier. There’s a notice-

able cushioning of hammer blows when

hand-driving nails into shingles applied

over Home Slicker. The bounce makes it

hard to start nails in the shingles. You

must also use fasteners long enough to

pass through the vent space and pene-

trate all the way through the sheathing.

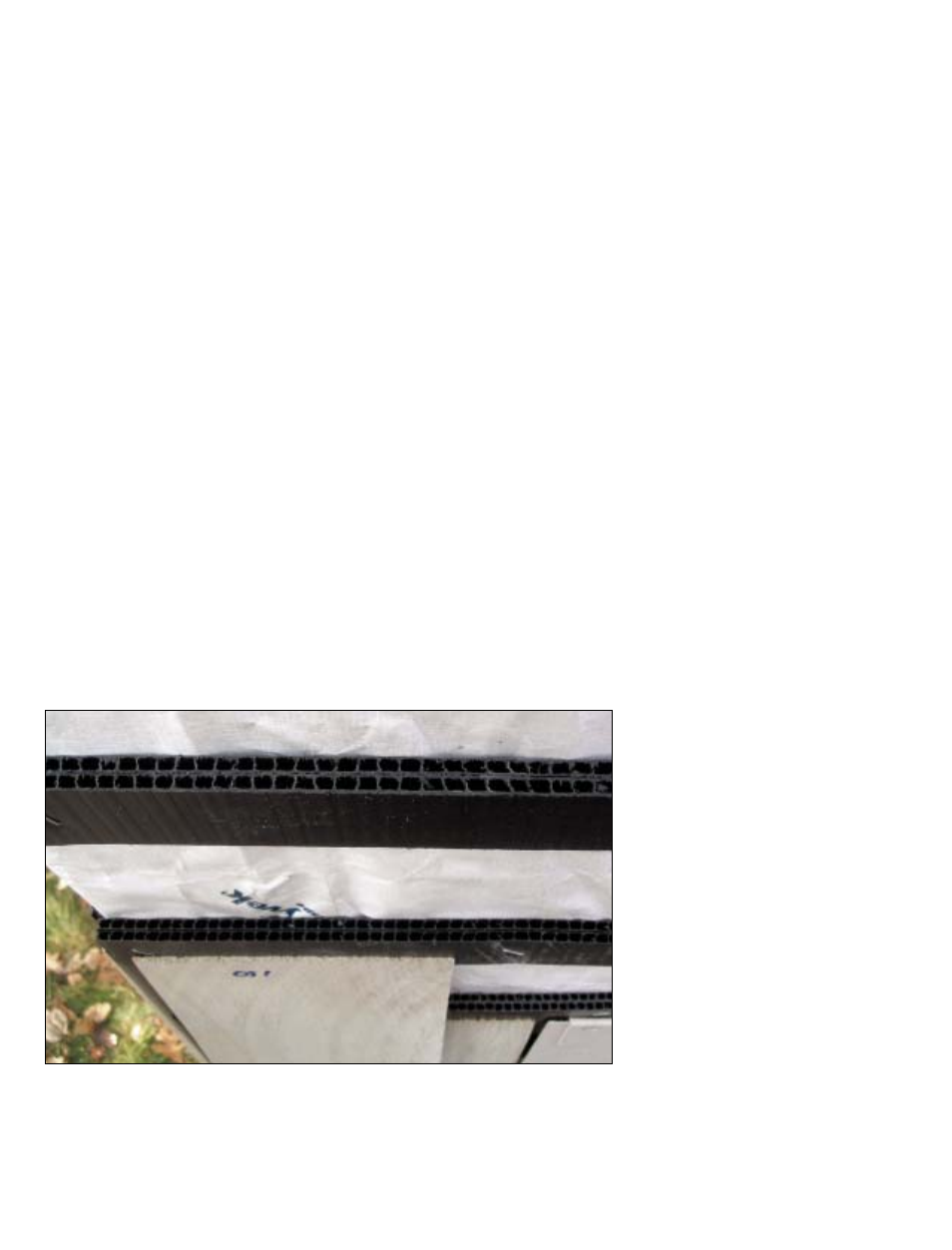

Plastic battens. Corrugated plastic

battens offer a good alternative to my fur-

ring-strip rain screen. These have hollow

channels that let water and air flow

through them (Figure 2).

The only ones I’ve found marketed

specifically for shingle installation are those

from DCI Products — CedarVent and

RafterVent — but similar products are

available (see “Resources,” page 7).

Standard CedarVent comes in strips 3 feet

long. The four-ply version is

3

/

4

inch thick

by 2

3

/

4

inches wide. But a two-ply version

that’s just

3

/

8

inch thick (my preference)

and a three-ply version that’s

9

/

16

inch thick

are also available. While 1

1

/

2

-inch-wide

strips can be special ordered, I typically just

rip the two-ply version in half (from 2

3

/

4

inches down to 1

3

/

8

inches) to save mate-

rial and expose more of the shingle back to

the air. CedarVent is wrapped with a thin

fabric to keep insects out, so it’s great along

the undercourse at the bottom of the wall

and last course at the top. RafterVent can

be used instead of CedarVent in the field of

the wall. It’s essentially CedarVent without

the fabric wrap.

Battens require precise placement, so

they aren’t as fast to install as spacer

mats, but they do provide solid support for

nailing. I lay out a story pole for shingle

course exposure and use it to mark loca-

tions for the battens. After I transfer these

layout marks onto window and door trim

and corner boards, I snap chalk lines on

the housewrap between my marks. The

battens get applied above the lines. Since

shingles are nailed about 1 inch above the

butt line of the overlapping course, the

battens are positioned perfectly behind

the nail line. Extra battens are needed

under windowsills and horizontal band-

board trim elements to support the top

edges of the shingles.

Other than selecting longer fasteners,

there’s no special precaution to applying

shingles over battens.

TRIM DETAILS

The devil is always in the details. Corner

boards, woven corners, window and door

trim, band boards, and other trim elements

Best-Practice

Wall Shingles

March/April 2007

~

CoastalContractor

FIGURE 2.

Plastic battens have hollow channels that let water and air flow through them.

Shown here is the two-ply version of CedarVent, which the author rips to 1

3

/

8

inches wide

to save material and expose more of the shingle back to air.