Installation, Electrical connections – Mody Pumps MSPG Series User Manual

Page 4

2

After a long period of storage, the pump must

be inspected carefully. Rotate the impeller by

hand before start-up and check carefully

seals and cable entry

WARNING! Never start up the pump without

impeller. This will damage (in a few seconds)

the O-ring that seals between the rotor-shaft

and the sleeve of the mechanical seal

cartridge. Both sleeve and rotor shaft could

also be damaged due to excessive friction!

Installation

When installing the pump, reduce the risk of

accidents. Be aware that the machine is

extremely heavy and that it contains electrical

open wires.

Before starting the installation, check and

secure all screws for the lifting handle, stator

and volute fixing bolts. Ensure that these are

all safety tightened.

Lifting chains, cranes etc. must always be

designed to fully accommodate the weight of

the complete pump units. For safety reasons

never walk under suspended load.

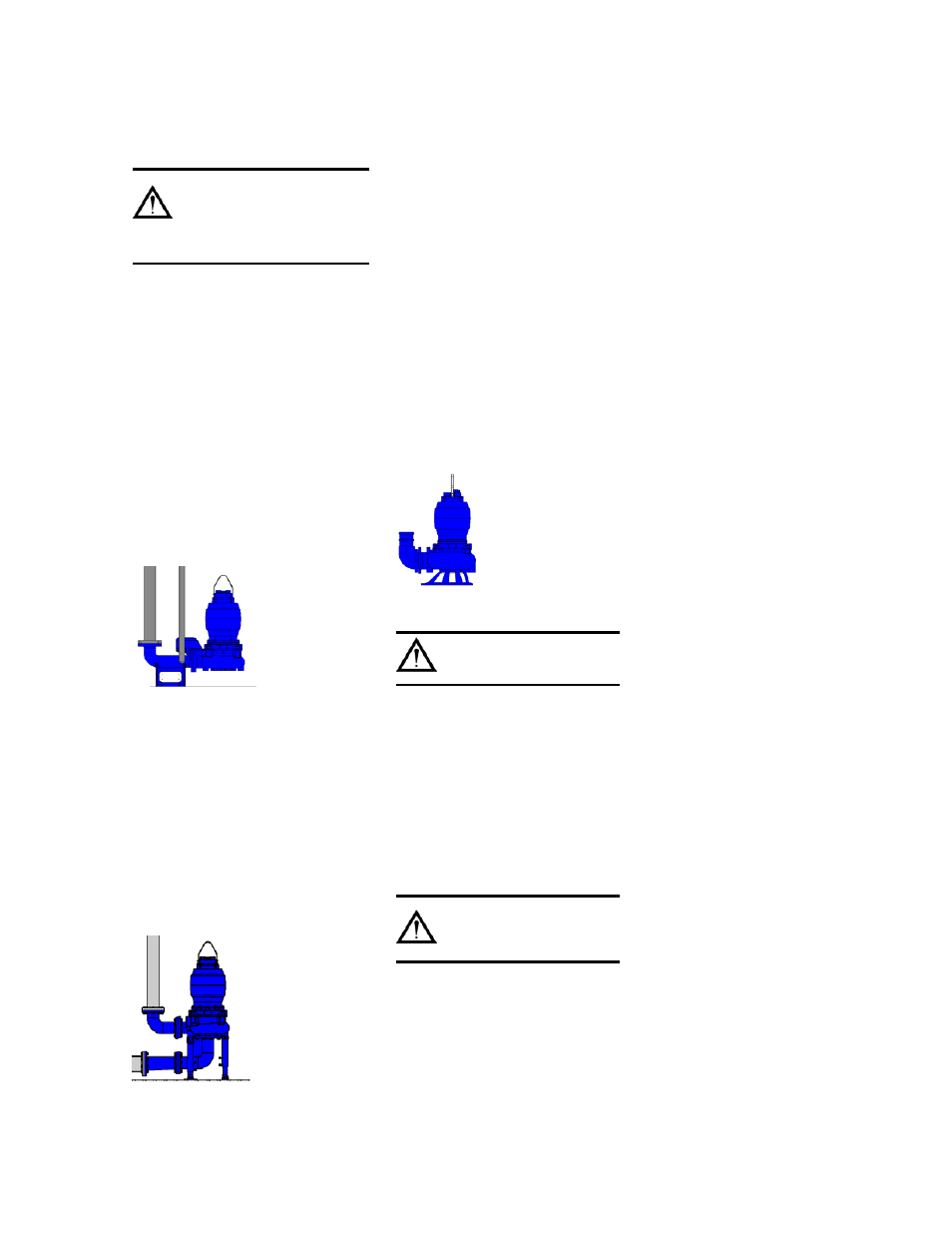

Discharge base elbow - DBE

Place the

discharge base

elbow (DBE) at

the bottom of the

sump. If one

pump is installed,

place the pump in

the center of the

tank. Fit the guide

rails to the upper

guide rail bracket so the rails are accurately

located in vertical and parallel positions to

each other.

Connect the discharge pipe to the DBE. A

non return valve and gate valve sized

according to the flow velocity from the pump

are strongly recommended.

The lifting tackle must be installed directly at

the point above the center of gravity of the

pump for proper automatic coupling to and

release from the DBE, which is appropriately

designed for this purpose, when lifting and

lowering the pump from and to the DBE.

Dry pit installation

All MSP2 and

MSP3 modules

can be installed

dry with adjust-

able support legs

and a separately

supplied suction

elbow, or a fixed

suction base

elbow (SBE) unit.

Adjustable sup-

port consists of

three legs that are

telescopic in design. The suction pipe can be

connected in any direction by changing the

location of the legs. After elevation

adjustment, the legs are set and fixed by

two screws that lock the pump

arrangement into position. The bottom leg

pads can then be secure by bolting and

anchoring them in the concrete foundation.

The suction pipe is connected vertically to

the pump suction flange.

Note: The motor unit is easier to remove or

re-install if the suction pipe is equipped

with a drain valve. This can be opened

when the motor is going to be or removed

or reinstalled.

The discharge pipe should be equipped

with a drain valve as well, in order to bleed

air from the system during first start-up.

Afterwards this valve can be fitted with a

manometer to measure the discharge

pressure.

Before starting, carefully inspect the cables

for defects and check the level of coolant

in the cooling jacket.

Portable version / installation

This version needs

extra attention while

operating. The pump

can be supplied with

a support ring.

Place the pump on a

firm surface. Keep

the cables straight

and secure so that they cannot be nipped

or cut in any way.

WARNING! Never remove the support ring,

human contact might occur and make

injury.

If there is risk of overturning, place and fit

the pump on a steel plate.

When hoses are used as discharge

connection, remember that friction losses

are higher than in a pipe and flow may be

less than expected.

Electrical connections

The electrical installation must be

inspected by authorized electrician before

switching-on.

CAUTION! All electrical equipment must

always be earthed (grounded). This applies

both to the pump and to any monitoring

equipment.

Make sure that the electrical terminals and

starting equipment is installed in such way

that it cannot be flooded. The electrical

installation must apply to national and local

regulations.

All pumps are supplied with built-in thermal

switches in the stator windings. These are

marked F1, F2 on the control cable and

must always be connected in series to the

control circuit in the control panel.

The control cable marked D is connected

to the moisture sensors. This cable should

be connected to a conductive liquid level

relay in the control panel. An alarm should

be given in event of moisture intrusion.

Your local MODY representative can

supply you with the conductive liquid level

relay as an option.

Make sure that the power supply, voltage,

frequency and starting method

corresponds to the nameplate data fitted

on the pump.

The motor can operate by voltage

tolerances at +/- 10%. The motor might be

overloaded and burned out if this is

exceeded.

For power supply cable, and control cable

connections, refer to the motor winding

connection schematics in this manual.

•

Direct online starting DOL

•

Star-Delta starting Y-∆

Starting equipment in the control panel

must be provided with over current

protection sensitive to phase failure. A 3-

phase asymmetry control relay is

recommended, adjusted to 15% phase

asymmetry

The power supply should be fused with

low-blow fuses.

15 Starts per hour (regularly spaced) are

permitted

Replacing the power cable

If the cable has been compressed or

damaged it must be replaced to avoid

water entry.

When changing the cable always change

the rubber cable seal was well. Never

change cable dimensions from the original

cable or cable seal dimensions from the

original seal, as water may enter the motor

if these are not properly sized.

If the same cable is re-used due to any

repair work, always cut away a piece at the

cable entry in order to seal on a non

compressed cable sheath.

For safety reasons the grounded conductor

strand should always be longer than all the

other conductor strands. If the motor cable

is accidentally wrenched off, the grounded

conductor should be the last to break away

from its terminal. This applies to both ends

of the cable.

Electromagnetic Compatibility,

EMC

The pump does not generate any

electromagnetic (EMC) that would affect

other equipment. However, if the pump

power is supplied by a frequency inverter,

the power cables may require screening.

All MSP2 and MSP3 pump modules

comply with directive EN89/336/EEC

regarding EMC.