Mody Pumps MSPG Series User Manual

Page 3

1

Contents

Identification plate

1

General description

1

Applications 1

Product description

1

Handling

1

Installation 2

Electrical connections

3

Operation

3

Service & maintenance

3

Technical data

Motor winding connection schemes

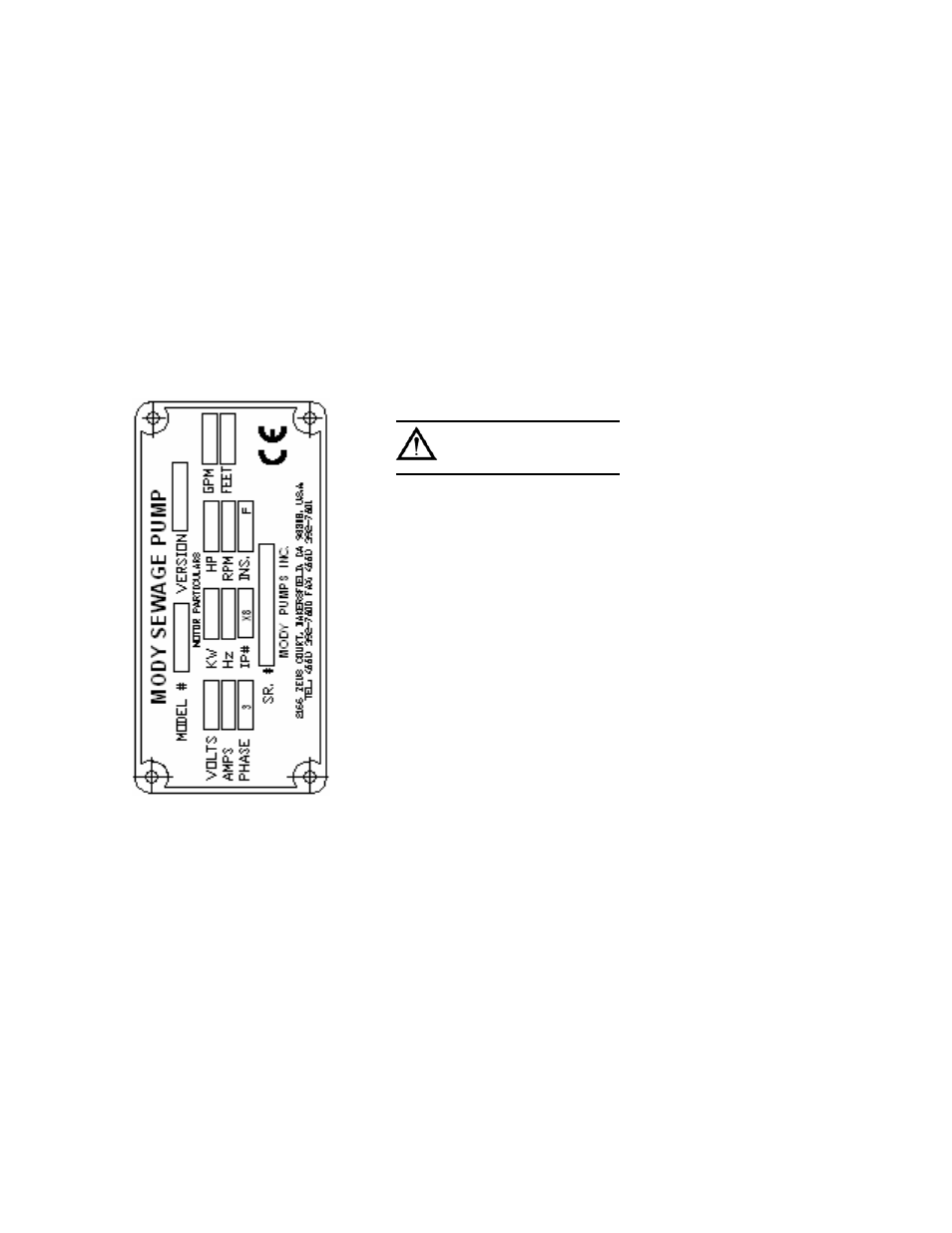

Identification plate

General description

The MODY MSP SERIES submersible

sewage pumps can be used in a variety of

residential, commercial and industrial

applications such as:

• Sewage

System

•

Flood and Pollution control

• Dewatering

/

Effluent

• Farms

• Hospitals

• Trailer

Courts

• Hotels

MODY MSP SERIES pumps are subjected to

a thorough inspection before leaving the

factory and equipped with operating

instructions for fitting, starting, care etc. which

conform to international safety regulations.

These instructions describe the procedures to

be used for fitting, operation and

maintenance of standard submersible

waste water pumps.

Applications

This starting & operation manual are

applicable to the electric driven

submersible waste water pumps specified

on the front page. The pumps are

designed to be used for pumping raw

sewage water with solid contents. The

pumps are suitable for heavy duty

drainage applications and clean water too.

The manufacturer guaranties that the new

pump airborne noise level do not exceed

70 db(A) when submerged. For dry

installation the corresponding level is

75 db(A). Be aware that under wrong

operated duty points, noise level might be

higher.

Caution! This range of pumps is forbidden

to handle in flammable liquids nor used in

explosive environment.

Do not start the pump if any parts

belonging to the pump are missing.

If humans should be in contact with the

pumped liquid e.g. construction sites, lifting

stations etc. a grounded connection

including an earth leakage detector must

be used. Never install the pumps in

swimming pools, special regulations apply.

Product description

Limitations

Immersion depth to max 20m (66 ft ).

Media temperature up to 40

o

C (115

o

F ).

Higher media temperature on request.

Pump models

Example: MSP

G2-50.X VX3 2-200

MSP

G2 = module range

50 =

standard outlet discharge in mm

X = version of volute

V = vortex impeller or

C = channel impeller

X =

version of impeller, more than

one X can appear to indicate

other types.

3 =

family pumps

2 = number of poles (rpm)

e.g.

2=3,500 rpm

200 = diameter of impeller in mm

Motor

3 phase squirrel cage induction motor for

60 Hz, degree of protection IP68,

insulation class H (180°C).

Motor protection

All stators are equipped with 3 built-in

thermal switches and are connected in

series which opens at 135°C and closes at

approx 90°C and are marked F1 & F2

control cable. To maintain warranty on the

pumps, these thermal switches must be

connected in series to control circuit of

control panel.

Cooling system

Models MSP2, MSP3 are standard

equipped with a closed internal cooling

system in all 3 types of installation, but can

be ordered without this system as an

option. Note that if ordered without closed

internal cooling system cannot be installed

as dry pit

The closed internal cooling system

functions as follows:

An internal impeller, located between the

two mechanical shaft seal, circulates the

cooling liquid in a closed loop through

channels to a cooling jacket surrounding

the stator housing. Thus, the heat

generated by the motor, is transferred to

the cooling liquid and finally dissipated to

the pumped liquid via a cooling flange

(heat exchange), without any physical

contact by the pumped sewage media.

Coolant: 70% water and 30% propylene

glycol.

Moisture sensor

All pumps are supplied with 3 moisture

sensors made of aluminum.

One sensor is placed in the seal oil

chamber; another sensor is placed in the

lower motor stator housing and a third

sensor is placed inside the motor cable

terminal board area.

The moisture detection control cable is

marked D. This control cable should be

connected to a relay (optional or by others)

in the control panel, which is activated by a

decrease in resistance to ground. Set the

alarm between 20 - 100 kOhm. Voltage

output applied to the moisture cable 12 -

24 VAC.

Power Cable

The pumps are standard equipped with

10m electric cable of the type H07RNF. If

longer cable is required, voltage drop must

be taken in consideration.

Handling

When transporting the pumps they must be

properly secured. Special attention must

be give to the cables; these cannot

withstand rolling heavy parts. All pumps

must be securely stored in vertical or

horizontal positions.

Always protect cable ends from moisture

and water as well, so that no moisture will

penetrate into the cable.

Before lifting the pump, check to determine

if the handle on the pump is properly

attached. Always use the lifting handle. Do

not use the cables or discharge hose. All

fixing screws and bolts must be securely

fastened before lifting. Human injury may

result if above is not properly secured.