Meriam MANOMETERS User Manual

Meriam Tools

5. Connections to Process

It is necessary that the instrument be properly connected to the

system in order to obtain a significant and accurate indication. All

connections must be leak-free.

U-Tube Manometers — Either high or low pressure may be con-

nected to either side of the instrument, provided that the difference

between them is within the indicating range of the instrument.

Well & Inclined Tube Manometers — Vertical and incline tube

manometers require more careful consideration. Basically, the

indicating fluid will move towards the low pressure and away

from the high pressure, until a hydrostatic balance has been

reached. In many cases it is possible that atmospheric pressure can

be considered as the high pressure. By noting the liquid level in

the filled manometer, it is possible to deduce whether the visible

level should be moved up or down to produce visible readings. By

knowing which of the two pressures is greater (as measured from

zero psia), the proper choice of meter connections can be made. It

may be noted that in flow metering work using orifice plates the

upstream pressure is greater than the downstream. For pitot tubes

the impact pressure is greater than the static pressure.

General Installation, Operation & Maintenance Instructions for

MERIAM MANOMETERS

1. Uncrating & Inspection

Carefully unpack the instrument. Make a thorough check for pos-

sible shipping damage. Remove all protective cushions or plugs. If

damaged, notify carrier and Meriam of damage. Be certain all items

on packing list are removed from container.

2. Mounting

Mount the instrument at a convenient height for reading vertically

on wall, panel, or table depending on mounting style. Be certain

instrument is level. Check with level on side and front of instrument

case. If instrument is furnished with a built-in level, use it to insure

level mounting. Table mounting stands are shipped separate from

instruments. Therefore attach the stand to the instrument.

3. Scale Adjustment (most models)

Position the scale at the center of the adjustment span.

4. Filling

U-Tube Manometers — Remove the top manometer head or fill

plug. Be sure instrument is properly vented on the low pressure

side. Slowly pour the selected manometer indicating fluid into the

glass tube until the indicating fluid level is at approximately the zero

graduation on the scale. Be sure all air bubbles are eliminated. Re-

place the head tightly. Adjust the scale for the correct zero position

in relation to the indicating fluid meniscus.

Well Type Manometers — Remove the fill plug on the well. Be

sure instrument is properly vented on the low pressure side. Slowly

pour the selected manometer indicating fluid into the well until the

indicating fluid level is at approximately the zero graduation on the

scale. Be sure all air bubbles are eliminated. Replace the fill plug

tightly. Adjust the scale for the correct zero position in relation to

the indicating fluid meniscus.

Inclined Tube Manometers — Remove the fill plug. Be sure to

check the instrument scale before filling to be certain the correct

indicating fluid is being used. Most inclined tube manometers use

Meriam 827 Red Oil or Meriam 1000 Green Concentrate. For ac-

curate measurements, it is critical to have the correct indicating fluid

in the instrument! Be sure instrument is properly vented on the low

pressure side. Slowly pour the selected manometer indicating fluid

into the well until the indicating fluid level is at approximately the

zero graduation on the scale. Be sure all air bubbles are eliminated.

Replace the fill plug tightly. Adjust the zero position by adjusting

the scale or the zero adjustment knob on the well, depending on the

model involved.

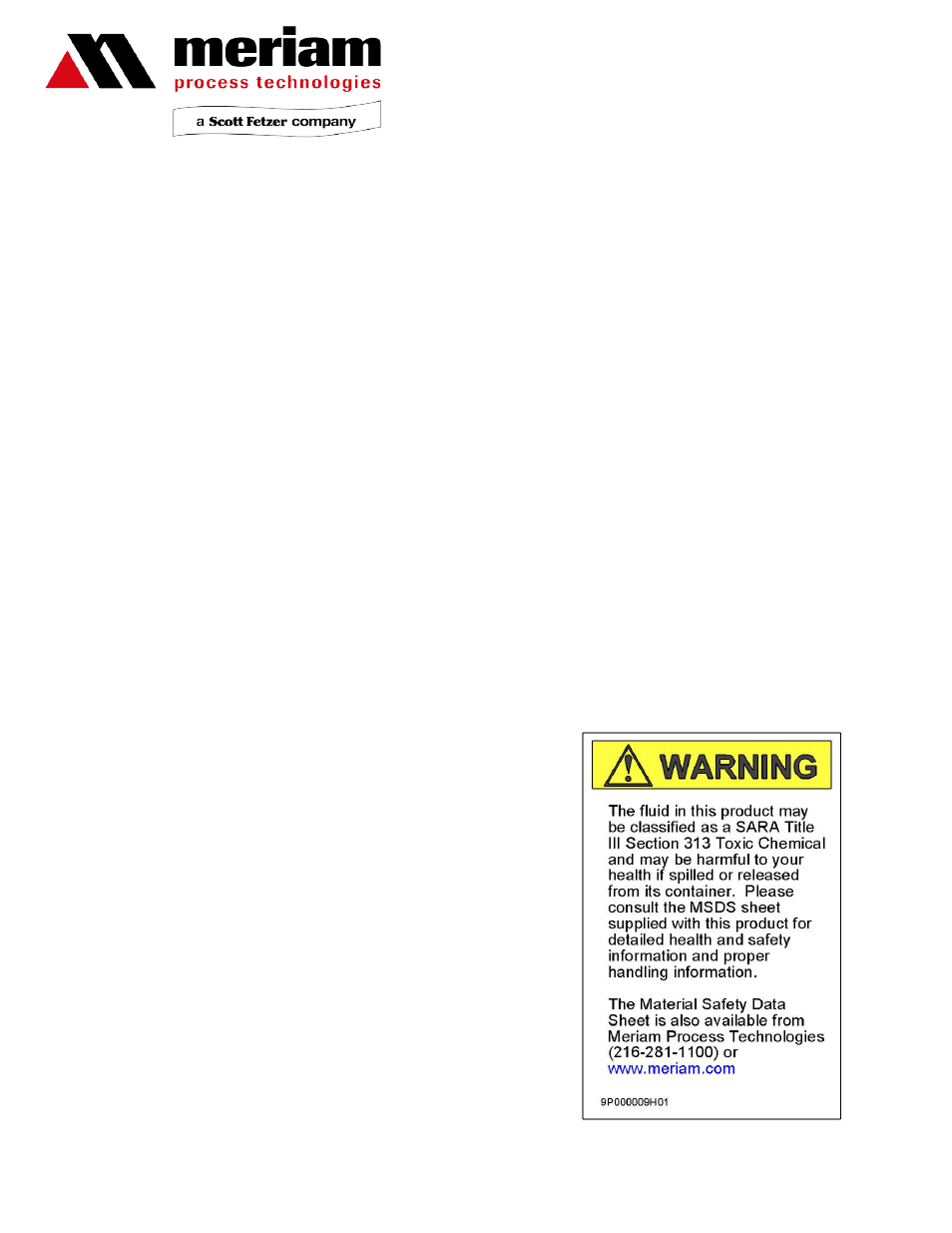

** THESE INSTRUMENTS MAY CONTAIN MERCURY.

PLEASE RECYCLE OR DISPOSE AS HAZARDOUS

WASTE ACCORDING TO LOCAL, STATE, AND FEDERAL

REGULATIONS. Consult Material Safety Data Sheets (MSDS)

for handling information and safety data.

Instruction Sheet

F/N: 022C:440-14

E.O. # 5946