Meriam Laminar Flow Elements User Manual

Page 14

14

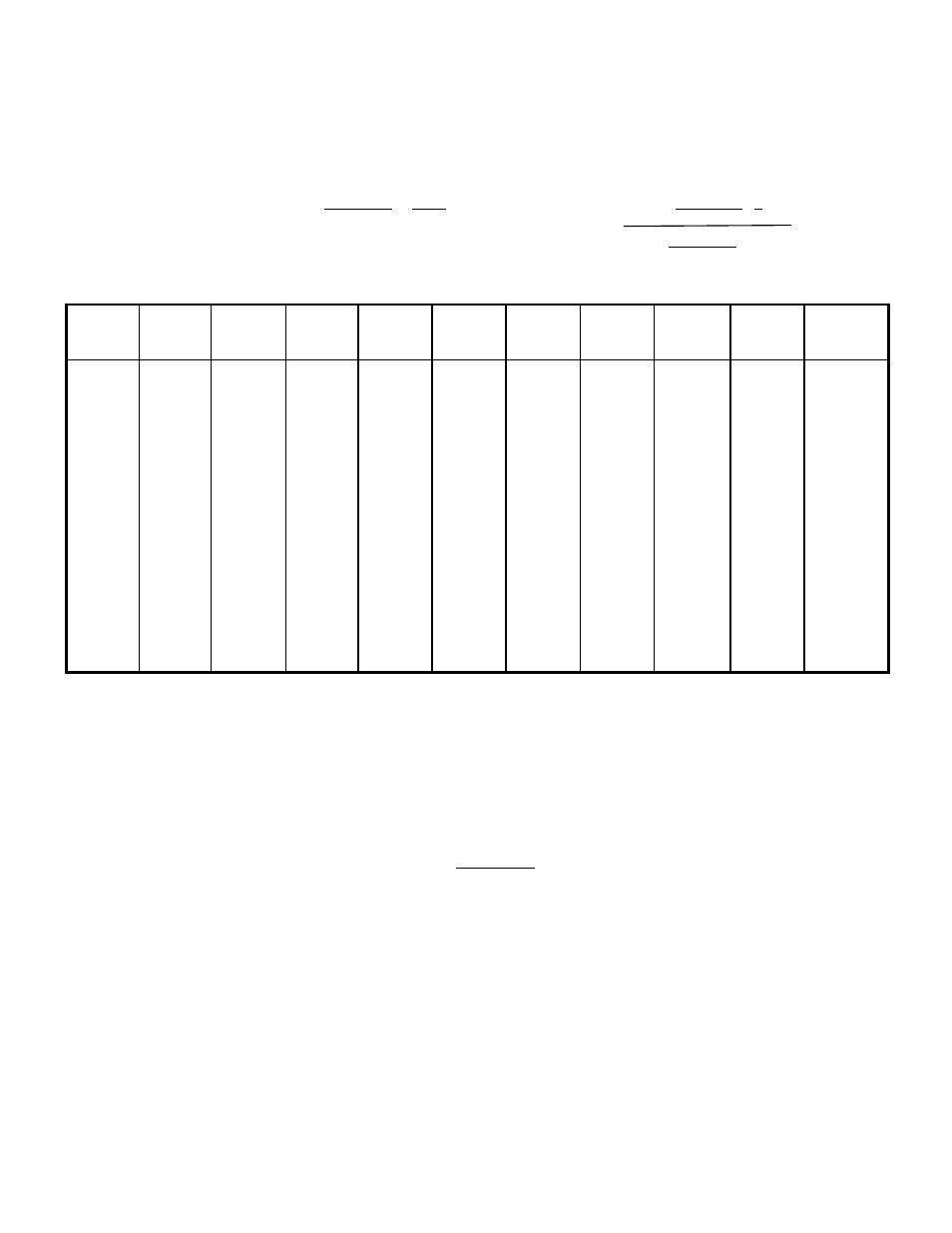

Table A-32422

A i r T e m p e r a t u r e / V i s c o s i t y C o r r e c t i o n F a c t o r s f o r S C F M A i r B a s e

T e m p e r a t u r e 7 0 °F 181.7 Micropoise Reference NBS Circular 564

Correction Factor =

ૢ.ૠ

ૢ.ૠା °ࡲ

x

ૡ.ૠ

ஜ∗

µair = 14.58 x

ቀ

ૢ.ૠା °۴

.ૡ

ቁ

110.4 +

ቀ

ૢ.ૠା °۴

.ૡ

ቁ

Temp

°F

+0

+1

+2

+3

+4

+5

+6

+7

+8

+9

50

60

70

80

90

100

110

120

130

140

150

1.0707

1.0344

1.0000

.9674

.9365

.9072

.8793

.8528

.8276

.8036

.7807

1.0670

1.0308

.9966

.9642

.9335

.9043

.8766

.8503

.8252

.8013

.7785

1.0633

1.0273

.9933

.9611

.9305

.9015

.8739

.8477

.8227

.7990

.7763

1.0596

1.0238

.9900

.9579

.9275

.8987

.8712

.8452

.8203

.7966

.7741

1.0559

1.0204

.9867

.9548

.9246

.8959

.8686

.8426

.8179

.7943

.7719

1.0523

1.0169

.9834

.9517

.9216

.8931

.8659

.8401

.8155

.7920

.7697

1.0487

1.0135

.9802

.9486

.9187

.8903

.8633

.8376

.8131

.7898

.7675

1.0451

1.0101

.9770

.9456

.9158

.8875

.8606

.8351

.8107

.7875

.7653

1.0415

1.0067

.9737

.9425

.9129

.8848

.8580

.8326

.8083

.7852

.7632

1.0379

1.0033

.9705

.9395

.9100

.8820

.8554

.8301

.8060

.7830

.7610

* When flowing gas other than air, use the viscosity in micropoise of the gas at flowing temperature in

the Correction Factor equation.

Table A-35700

Temperature Correction Factor

Base Temperature = 70°F

Tcf =

ૢ.ૠ

(ૢ.ૠା °۴)

Maintenance

Accumulation of dirt in the capillaries of the laminar element will affect the accuracy. When in

doubt, hold the laminar in front of a high intensity light, sighting through the capillaries. Any dirt

will be apparent. Loose dirt can be blown out with shop air (no more than 100 PSI) in reverse direction

of flow. Shop air must be clean and dry. Brushing or rubbing the ends of the matrix element is not

recommended because the matrix can be deformed, altering the calibration. Unless the customer has the

facilities and primary standards to check calibration after cleaning, we recommend returning the unit to

Meriam for cleaning and calibration.