Removal from flow meter, Moisture protection, About explosion proof installations – Max Machinery Explosion Proof Install User Manual

Page 2: Electrical installation

33A

Healdsburg Avenue

Healdsburg,

CA 95448

T

+ 1 707.433.2662

F

+ 1 707.433.1818

Max Machinery, Inc.

maxmachinery.com

EXInstallEnglish_001Q2.pdf • Rev2 • © 08/14/2013 Max Machinery, Inc.

`

Removal from Flow Meter

Note: the transmitter does not need to be removed from the flow meter for any field servicing or adjustments. Normally,

the flow meter and transmitter are shipped back to the factory for calibration as a unit.

1. Remove the locking screw at the edge of the lid and then remove the cap using a 3/8” socket drive.

2. Disconnect wires at the terminal block and remove wiring conduit from transmitter.

3. Locate the locking set screw below the conduit hole and remove it. Rotate the outer housing clockwise until the screw

hole lines up with a hole in the inner housing. (Inserting an Allen key into the threaded hole while rotating the housing

can help in finding the point of alignment.) Now re-insert the set screw and hand-tighten it. This will lock the inner and

outer housing together.

4. Unscrew the transmitter, using a strap wrench if necessary.

Moisture Protection

The housing is a liquid and vapor-tight enclosure certified to IP66. There is an O-ring seal at the lid of the housing — the

seal needs to be fully seated to provide moisture protection and achieve flameproof specifications.

About Explosion proof installations

For the Model EX295 and EX296 to fully adhere to the HazLoc certifications, the wiring must meet the appropriate

codes. (Use of a wire conduit does not make the installation explosion proof – read below.) The transmitters which are

certified for use in hazardous locations require the use of a 1/2” NPT hazardous location rated conduit fitting. The

wiring conduit must be sealed with a conduit stop within 18” of the device. If you choose to use exposed cables, cable

seals must be used with sealing fittings and the wiring must be an approved armored cable. (For detailed information on

the joint constructions used to achieve a flame proof housing, please contact Max Machinery.)

Electrical Installation

The transmitter includes a wiring pigtail and 2 part connector - use of the pigtail is optional and direct wiring to the

PCA is recommended if the circuit board is accessible. Use wiring that is between 20 and 28 gauge and rated to at least

5°C above the maximum ambient temperature, and rated to at least 80% of the maximum fluid temperature. Cut back

the cable bundles’ outer sheath several inches to make it easier to coil the wire loop inside the housing. The pigtail

connector’s terminals correspond to the terminal block on the PCA. Refer to the diagram below for wire number and

functions.

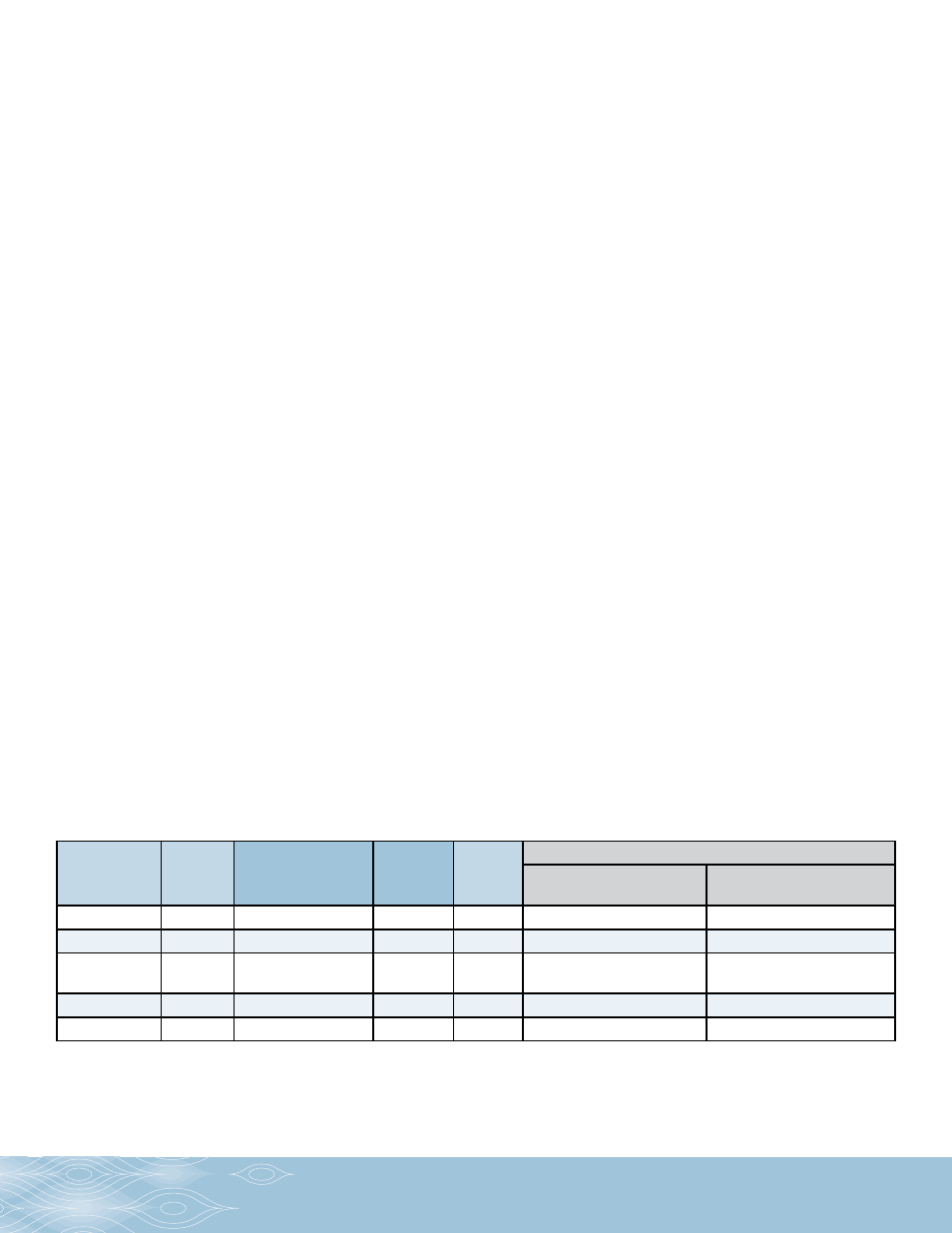

* Consult Electrical Requirements Table

Pulse Output

Wiring

Pulse

PCB

Label

Analog Output

Wiring

Analog

PCB

Label

Wiring

Adaptor

Pin #

Two Part Transmitter Wiring

Ex-Proof Sender

(Example: EX29x-051-000)

Remote Receiver

(Example: EX296-x8x-xxx)

Power *

V+

Power

V+

1

Case

Case

Common

Com

Common

Com

2

5V

5V

Signal

Output

PhA

Signal Output (+)

Sig

3

Ra

Ra

(Quad only)

PhB

Signal Output (-)

Ret

4

Rb

Rb

Case Ground

Case

Case Ground

Case

5

Com

Com