Flow rate setting – Magnum Venus Plastech CTS-9000 CAT SENSE User Manual

Page 19

Cat Sense Operations Manual

Rev. 11/2012

Page | 19

Flow Rate Setting:

In order to achieve the best response from the Cat Sense system it is necessary to

adjust the Cat Sense Body on the Flow Sensor Body to just below the normal catalyst

flow rate expected during production.

There are two considerations regarding catalyst flow which must be taken into account.

1. The flow rate is affected by the catalyst pump ratio setting. - A lower ratio setting on

the ratio arm results in lower flow, while higher ratio settings result in higher flow rates.

2. The pump output speed will affect flow in that the faster the pump is set to pump, the

higher the flow rate of catalyst whatever the ratio setting.

It is necessary to set the Cat Sense Body to a point just below the established

production flow rate. On MVP machines which have full recirculation capability, the Cat

Sense will operate during both recirculation & Mixer nozzle output. In this circumstance

it is a simple task to set the flow prior to production use by switching the machine to

recirculation and setting the Cat Sense Body at a level just below the pump speed and

ratio setting. - In other words, the Cat Sense Body is adjusted vertically to NOT alarm at

this output flow level.

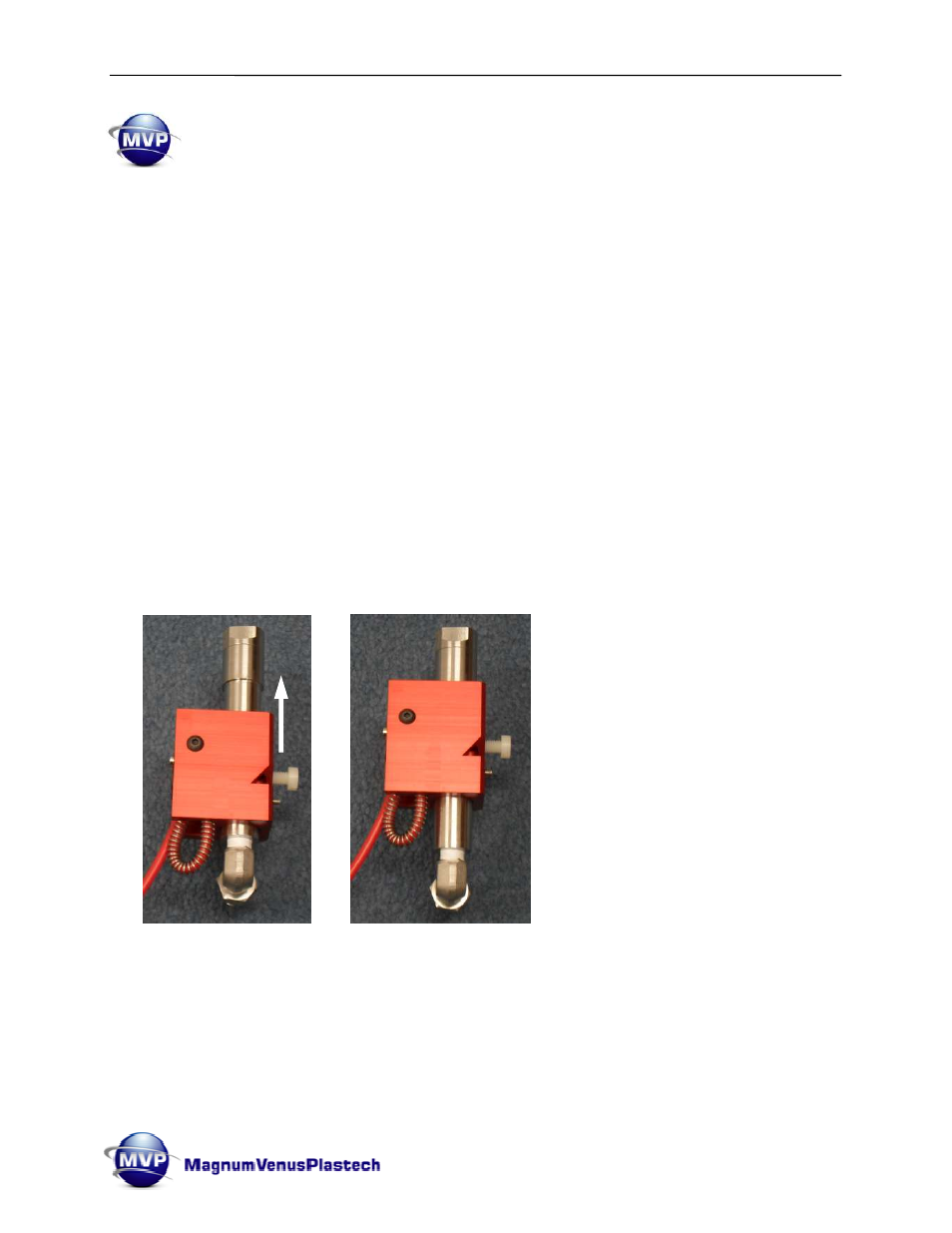

Referring to the photos above, adjust the Cat Sense to the desired flow position by

raising or lowering the Red Cat Sense Body on the Flow Sensor Body to increase or

decrease the flow rate, lock the Cat Sense Body in the position at which the alarm just

turns off. If Recirculation is not available then the above procedure is performed during

standard production output through the dispense head / spray gun. - To test this

setting, simply reduce the pump speed or the catalyst percentage, or open the ball valve

on the catalyst manifold to witness that the Cat Sense alarms as the flow reduces from