Mach III Clutch 118SI & 118SI-ULOW User Manual

Page 4

7/10/2013

CLUTCH_SENSIFLEX_SI_MANUAL

Page 4 of 5

Repair Parts & Services

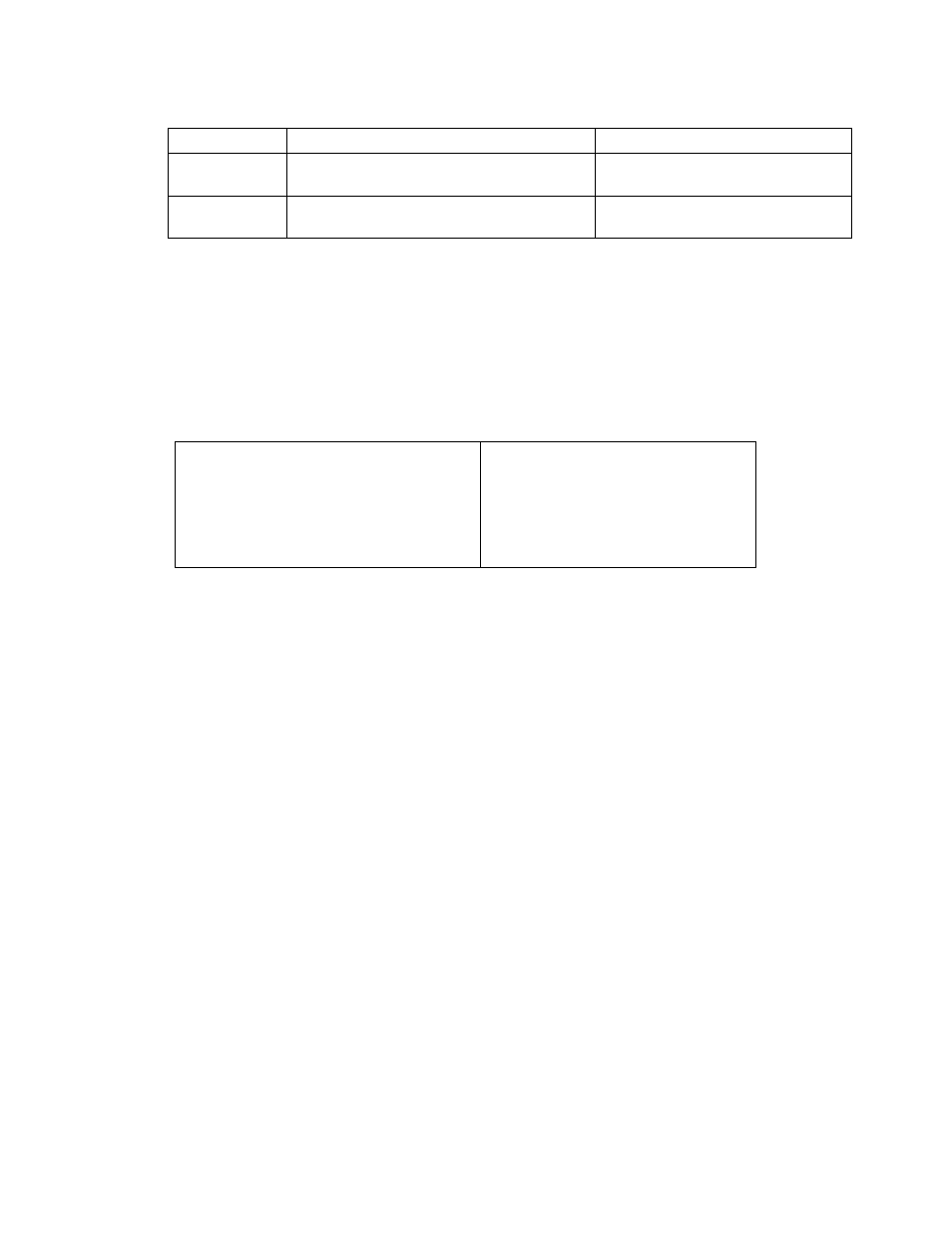

Kits Available

Contents

Part Numbers

Facing Kit

Friction Disc & Mounting Screws

38SI-FCGK, 38SI-ULOW-FCGK,

58SI-FCGK, Etc. . . .

Repair Kit

Friction Disc, Mounting Screws, Spring(s),

Diaphragm

38SI-RPRK, 38SI-ULOW-RPRK,

58SI-RPRK, Etc. . . .

For part numbers of components not included in the kits above, please contact Mach III Clutch,

Inc. or your distributor. Factory repair is also available. A return materials authorization (RMA)

number must be obtained prior to sending any unit in for repair. Mach III Clutch is not

responsible for products returned without authorization.

IV.

Repair Procedure

Tools Needed

Hex wrench set

Retainer (snap) ring pliers

Flat head screw driver

Scraper (if replacing bearings)

0.010 Inch feeler gauge

Compounds Required

Grease

O-Ring lubricant

Anti-Seize Lubricant

A. DISASSEMBLY

Loosen set screws using appropriate hex wrench and slide the clutch off of the shaft. Place the

clutch on a work surface with the air cylinder end of the clutch upward. Loosen the set screw

in the retainer nut and remove nut using a wrench or channel lock pliers. The air cylinder

bearing is a slide fit on the drive hub. The cylinder, piston and cone assembly should come off

of the drive hub together. You may need to strike the hub, or on an object inserted into the

hub with a rubber mallet or similar soft face hammer, while pulling the cylinder upwards to

remove.

B. DRIVE SURFACE INSPECTION & FRICTION DISC REPLACEMENT

Inspect the drive surface of the cast iron sleeve input member. Grooves in the surface would

indicate that the friction disc should have been replaced sooner and the heads of the mounting

screws have made contact. This surface must be free from grooves, burrs and foreign materials

in order for the clutch to operate properly. If damage is pronounced, please contact Mach III

Clutch or your distributor about replacing the sleeve and procedure. In addition, clutch should

be inspected for discoloration (turning blue). If discoloration is present, the unit is being

operated beyond its capacity and Mach III Clutch should be contacted for assistance. To

replace the friction disc, remove brass screws and friction disc, make sure mounting surface is

smooth and free from contamination. Mount new friction disc by snugging all screws first then

tighten firmly using an alternating sequence. Do not over-tighten.

C. INSPECTION OF BEARINGS

Check bearings for external damage (missing seals, etc.). Make sure the bearings rotate freely

and smoothly by hand. If bearing replacement is necessary, consult Mach III or your distributor

for the bearing sizes and replacement procedures.