Reference diagram, I. installation, Important – Mach III Clutch 118SI & 118SI-ULOW User Manual

Page 2

7/10/2013

CLUTCH_SENSIFLEX_SI_MANUAL

Page 2 of 5

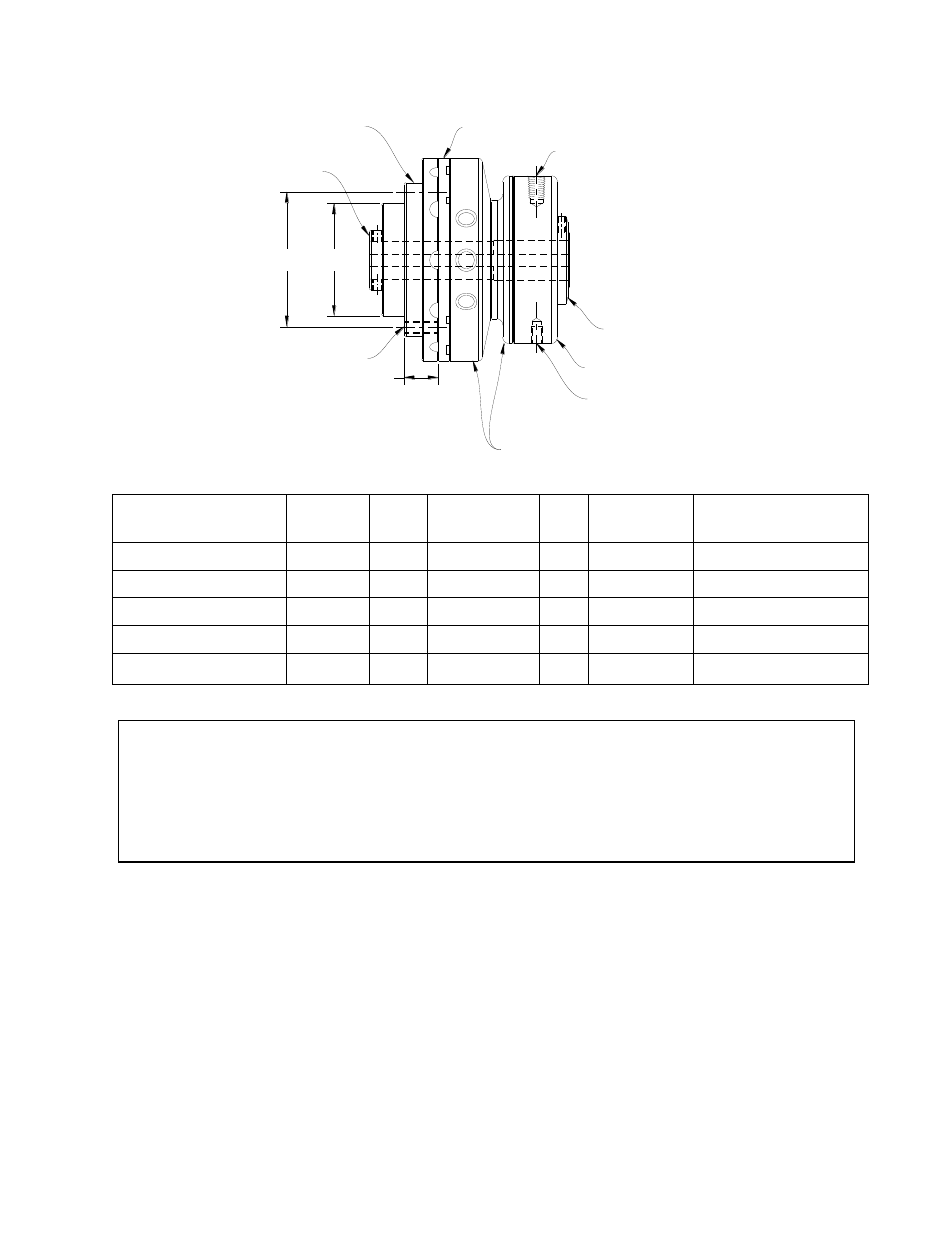

X

DRIVE HUB

INPUT MEMBER

FRICTION LINING

AIR INLET

RETAINER NUT

AIR CYLINDER

INPUT FOR REACTION ARM

E

PISTON - DRIVE DISC

ASSEMBLY

SLEEVE

OUTPUT MEMBER

H

BC

Reference Diagram:

I.

Installation

A. SHAFT PREPARATION & MOUNTING

Mach III Clutch products are bored to fit a precision plug gauge for the specified bore size

and should slide-fit your shaft. Make certain that the shaft is free of burrs or nicks. It

may be necessary to file or sand the shaft to assure a slide fit. Never hammer the clutch

onto the shaft. Hammering on the clutch may cause evident damage or subtle injury that

will shorten the wear life of the unit, and will void the warranty. Apply the anti-seize (E-Z

Break®) lubricant from the packet provided, or equivalent, to the shaft. Slide the clutch

over the key on the shaft, align the pulley or sprocket and tighten the set screws.

Product#

H

E

X

BC

Air Inlet

Reaction Arm Input

38SI/38SI-ULOW

1.875

0.61

(3) 10 - 24

2.25

1/16" NPT

10 - 24

58SI/58SI-ULOW

2.749

0.87

(3) 1/4 - 20

3.25

1/8" NPT

1/4 - 20

78SI/78SI-ULOW

3.875

1.20

(3) 5/16 - 18

4.50

1/8" NPT

1/4 - 20

98SI/98SI-ULOW

5.000

1.25

(6) 3/8 - 16

5.63

1/8" NPT

1/4 - 20

118SI/118SI-ULOW

6.250

1.50

(6) 7/16 - 14

7.00

1/4" NPT

5/16 - 18

**IMPORTANT**

The gap between the friction and drive surface is factory set between 0.010 and 0.020 Inch.

This is the ideal clearance for proper performance.

Increasing this gap may result in air leaks and damage to the diaphragm actuator.

Decreasing this gap prevents full disengagement of the brake.