Ii. operation, Iii. routine maintenance – Mach III Clutch 118SI & 118SI-ULOW User Manual

Page 3

7/10/2013

CLUTCH_SENSIFLEX_SI_MANUAL

Page 3 of 5

B. AIR LINE CONNECTION

Air supply should be both filtered and regulated. Contamination in the air supply will

cause damage to the clutch, particularly to the diaphragm actuator. Connect a flexible

airline to the air inlet using a thread sealing compound. Do not use rigid piping.

C. ANTI-ROTATION (REACTION) ARM CONNECTION

Install a reaction arm (bolt, rod, or other device) into hole provided. This is necessary

to prevent rotation of the air cylinder (due to the drag in the bearings) and to keep

pressure off of the air inlet. This arm should not be held rigidly.

Please refer to Mach III’s Anti-Rotation (Reaction) Arm Installation Instructions

document for illustrations of proper mounting. This document is available from the

Mach III website:

or by

calling Mach III to have a copy sent by email or fax.

D. FINAL INSPECTION & TESTING

Check alignment of the sprocket or pulley. Cycle the clutch with the machine off to

check for air leaks and to ensure proper engagement and release. After a short run,

check set screws and alignment.

II.

Operation:

The SensiFlex® clutch is designed for use in slip applications, typically to maintain tension on a

web during rewinding or a similar tension control application.

III.

Routine Maintenance:

Friction linings (discs) are a “wear” item and in a constant slip application, periodic

replacement of the friction disc will be necessary. The frequency of disc replacement varies

with each application. Screws are used to mount the friction disc on the drive disc. Wear of

the friction disc should be monitored so that it can be replaced prior to the point at which the

heads of the mounting screws would make contact with the input sleeve. See chart below for

replacement point recommendations. Mach III Clutch, Inc. should always be consulted to assist

with selection of a SensiFlex® Clutch to assure that required tension can be maintained while

dissipating the heat caused by constant slip.

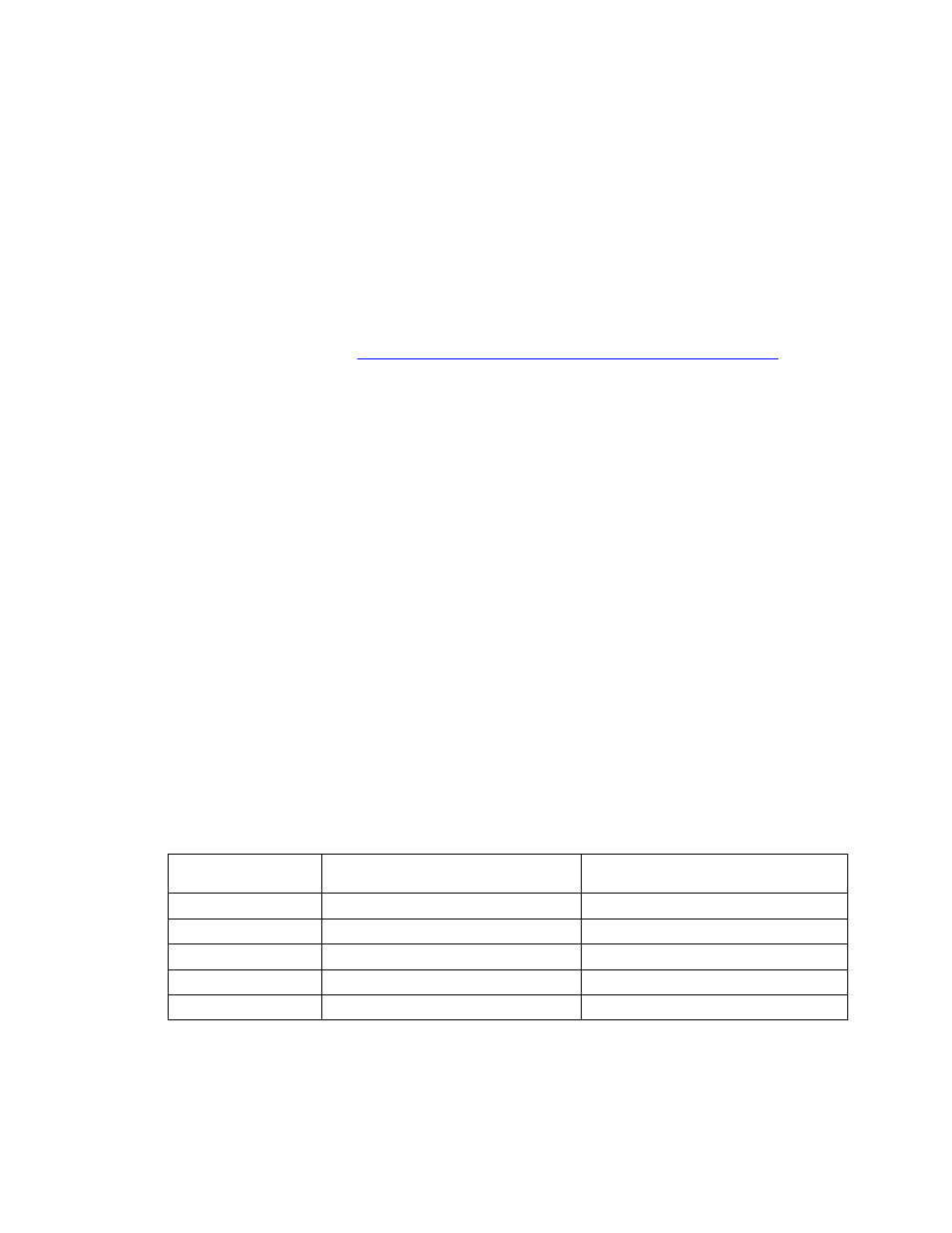

Friction Disc Replacement Recommendations

Product

Original Thickness

of Friction Disc

Replace When Worn To A

Thickness Of:

38SI/38SI-ULOW

3/16 Inch

9/64 Inch

58SI/58SI-ULOW

1/4 Inch

1/8 Inch

78SI/78SI-ULOW

5/16 Inch

3/16 Inch

98SI/98SI-ULOW

7/16 Inch

5/16 Inch

118SI/118SI-ULOW

7/16 Inch

5/16 Inch