A2882 (refined fuels), A2882 back check valves – Liquid Controls Back Check Valves A2885 & A2883 LPG, A2882 Refined Fuels User Manual

Page 5

5

a2882 (refIned fuels)

Refer to the illustrated parts breakdown on Page 7 for Item

Numbers referenced in these instructions. Item Numbers appear

in circles in the drawing.

Item Numbers

a2882 back Check Valves

neW InsTallaTIons

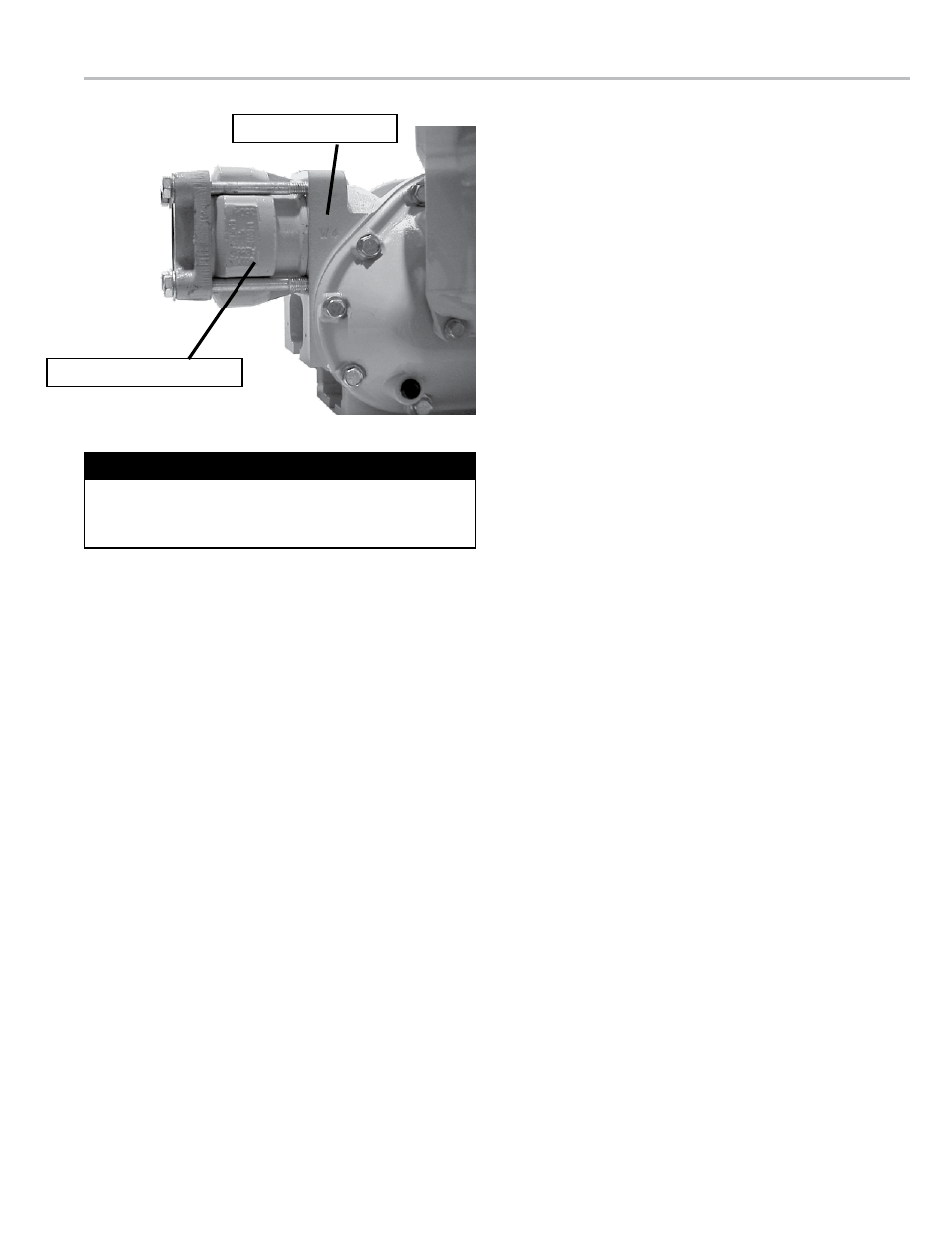

When ordered with a new metering system, the A2882

Back Check Valve is supplied mounted to the outlet

side of the meter as shown to the right. To complete the

A2882 Back Check Valve portion of the installation, a

liquid line must be connected to the flange on the outlet

side of the valve. The flange connection is 2” NPT.

reTrofIT InsTallaTIons

Depending on the existing configuration, adding an

A2882 Back Check Valve may require modification of the

outlet piping.

After the internal pressure is relieved from the

system (see warning on Page 2), the outlet line can

be disconnected from the output side of the meter

assembly. The valve and flange assembly can then be

connected to the outlet side of the meter.

Use the four bolts and washers provided to fasten the

valve/flange assembly to the meter. Tighten the bolts

in a crossing pattern (as shown on Page 4). Once the

valve/flange assembly is secure, the outlet line may be

reconnected to the flange. The flange fitting is 2” NPT.

dIsasseMbly

1. Remove the valve from the line by removing the four

screws (Item 3) and washers (Item 4) that hold it in place.

2. Using a tire valve stem changer, remove the relief valve

(Item 920) from the valve stem (Item 265).

3. From the inlet side of the valve, unscrew the valve stem

(Item 265) from the valve nut (Item 875).

4. Remove the valve nut (Item 875) by pressing down on

the spring holder (Item 382). The spring should be held

down with a press. Lift the valve nut out of position. The

spring holder and lock washer can now be removed from

the housing.

5. Remove the O-Ring retainer (Item 452), O-Ring (Item

470), piston (Item 133), O-Ring (Item 471) and spacer

(Item 472), lifting by the threaded end of the valve stem

(Item 265).

6. Remove the O-Ring retainer (Item 452) and O-Ring (Item

470) from the stem.

7. Remove the O-Ring (Item 471) and the piston (Item 133)

from the stem.

8. Replace components if necessary and reassemble. The

bushing (Item 485) is pressed in place and need not be

removed.

reasseMbly

1. Place the piston (Item 133) on the valve stem (Item 265),

with the raised rim pointing upwards.

2. Place the spacer (Item 472) and O-Ring (Item 471) on

the piston (Item 133)

3. Place the O-Ring (Item 470) on the retainer (Item 452)

and place it over the piston (Item 133) with the O-Ring

downward.

4. Place washer (705) over the valve stem and secure it

with self locking nut (875)

5. Insert this assembly into the housing (Item 110) from the

outlet side.

6. Place the compression spring (Item 595) over the valve

stem (Item 265).

7. Insert the Teflon bearing (Item 486) into the valve spring

holder (Item 382).

8. Place the spring holder (Item 382) on the housing (Item

110) and compress the spring inward. A press should be

used to overcome the force of the spring.

9. Secure the spring holder with the spiral retaining ring

(Item 393).

10. Screw the pressure relief valve (Item 920) into the valve

stem (Item 265) using a tire valve stem changer.

The back check valve is now ready to be reinstalled using the

four screws (Item 3) and washers (item 4).

2882 Back Check Valve

Meter Outlet