Warning, General information – Liquid Controls Back Check Valves A2885 & A2883 LPG, A2882 Refined Fuels User Manual

Page 3

3

InTroduCTIon / a2885 & a2883 (lPG)

!

WarnInG

Power, input, and output (I/O) wiring must be in accordance with the area classification for which it is used (Class I, Div 2).

For North America, installations must be per the U. S. National Electrical Code, NFPA 70, or the Canadian Electrical Code

in order to maintain Class I, Division 2 ratings. This may require using connections or other adaptations in accordance

with the requirements of the authority having jurisdiction.

WARNING: Explosion Hazard -

Substitution of components may impair suitability for Class I, Division 2 applications.

WARNING: Explosion Hazard -

When in hazardous locations, turn power OFF before replacing or wiring modules.

WARNING: Explosion Hazard -

Do NOT disconnect equipment unless power has been switched OFF or the area is known to be Non-Hazardous.

observe national and

local Codes

General Information

Liquid Controls soft seat Back Check Valves are designed to prevent reverse flow of product through the meter.

This assures that the meter and all components downstream remain full of the liquid being measured. The A2885

and A2883 for LPG are installed on the inlet side of the strainer assembly on the meter. The A2885 and A2883 are

applicable for MA-5 and MA-7 meters. The A2882 for Refined Petroleum products is installed on the outlet side of the

meter. The A2882 is applicable for M-5, M-7, and M-10 Meters.

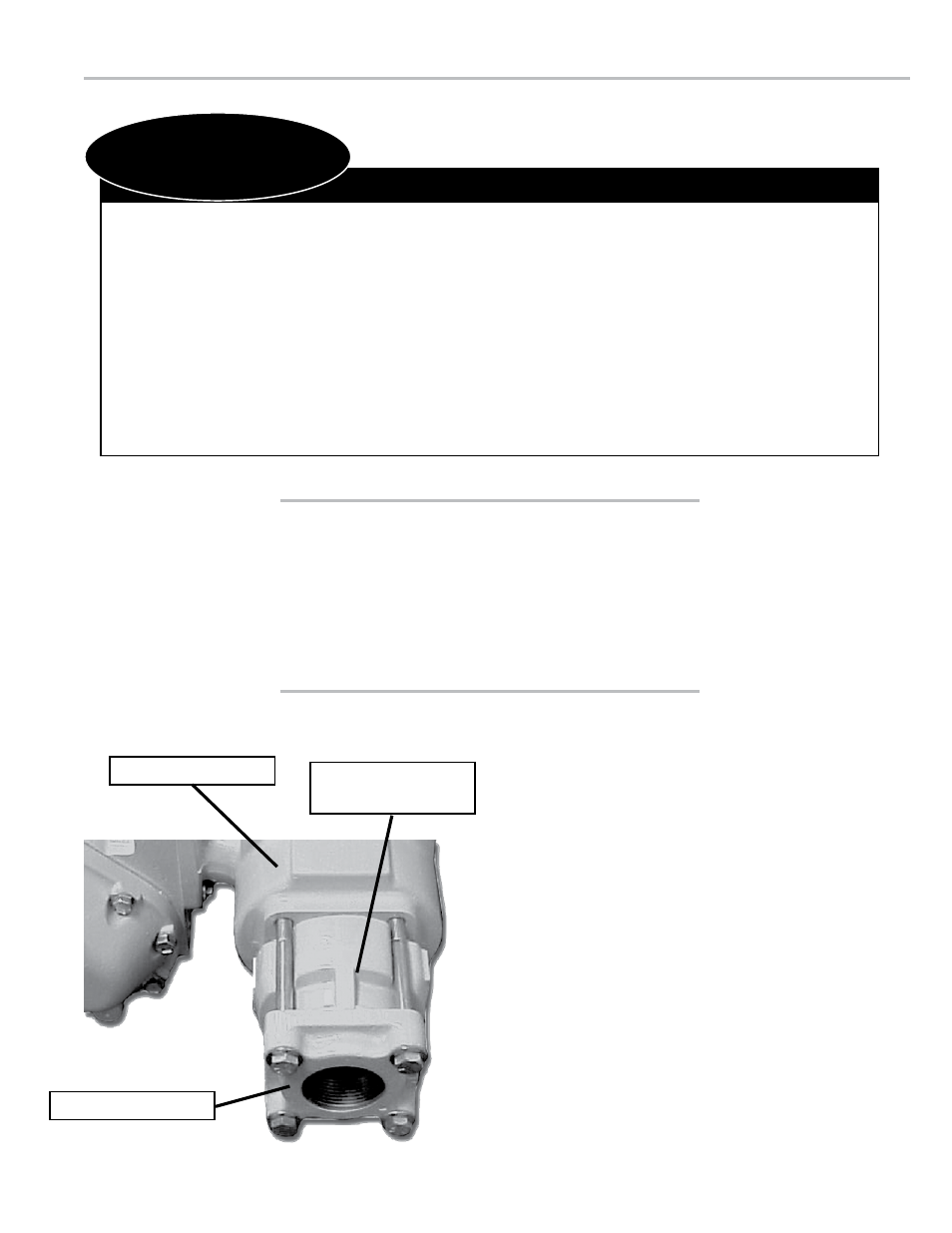

a2885 & a2883 back Check Valves

neW InsTallaTIons

When ordered with a new metering system, the A2885

or A2883 Back Check Valve is supplied mounted to the

inlet side of the strainer housing as shown to the right.

To complete the A2885 or A2883 Back Check Valve

portion of the installation, a liquid line must be connected

to the flange on the inlet side of the valve. The flange

connection is 2” NPT.

Strainer Assembly

2" NPT Flange (Inlet)

A2885 or A2883

Back Check Valve