Gate arm installation (cont.) – Controlled Products Systems Group SWG-111 User Manual

Page 7

SWG Swing Gate Operator Installation Guide

- 5 -

P1227 Revision X5 2-13-2013

Gate Arm Installation (Cont.)

Gate Plate Installation

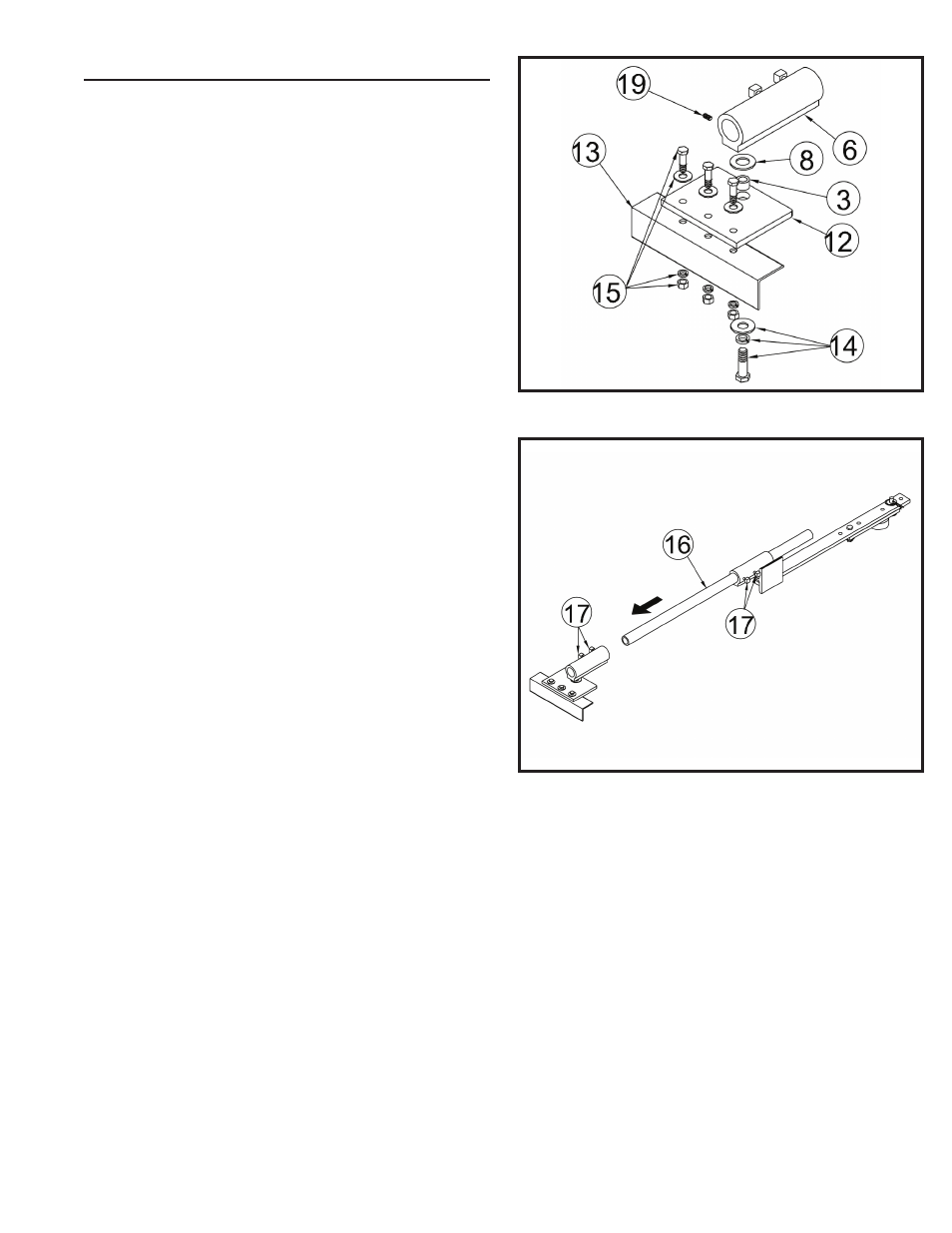

See Figure 6. Angle iron (not supplied) (13) should be

welded to the gate prior to this step. Attach the gate plate

(12) to the angle iron using 3/8 bolts, fl at washers, lock

washers and hex nuts (15). Slide a 1/2-13 x 1 1/4” bolt, 1/2”

lock washer, 1/2” fl at washer (14), and a black spacer (3)

through the gate plate. Place a nylon washer (8) over the

opening in the gate plate. Thread the bolt into the hole in the

gate clamp (6) and tighten carefully. Do not overtighten!

Tighten set screw (19) to further lock hex bolt (14) in place.

Choosing Good Harmonics

Good harmonics are necessary to minimize wear and tear

on the operator. The gate will have smoother starts and

stops when the arm is installed with good harmonics. The

gate will have smooth starts and stops when the gate arm

folds over itself when the gate is fully open. Avoid setting up

the gate arm where the crank arm is parallel to the gate leaf

when the gate is open.

Pipe Link Installation

See Figure 7. Slide the pipe link (16) through the arm

assembly as shown. Place the 5/16” square bolts in the gate

clamps (17) and tighten carefully. Do not overtighten!

Setting the Arm Lengths

Most installations will use the standard dimensions specifi ed.

If non-standard mounting is required, contact the factory for

information.

Figure 6. Gate Plate Installation

Figure 7. Pipe Link Installation